SFI SUBPRO

RAMS group in SFI SUBPRO

RAMS group in SFI SUBPRO

A new center for innovation-driven research on Subsea Production and Processing (SFI SUBPRO) started up in mid 2015 and will last for 8 years. The center is headed by Professor Sigurd Skogestad from the process systems group at the Chemical department, and involves key research groups at NTNU including the RAMS group. Professor Mary Ann Lundteigen from the RAMS group is the co-director and also part of the core team. For more information about the center see the center web pages https://www.ntnu.edu/subpro.

The RAMS group has carried out research in relation to subsea oil and gas systems since the mid 1980s. Focus has been on reliability assessment of drilling and well production systems, as well as subsea processing systems and subsea control systems. Our contribution into the area resulted in a new Professor in Subsea Reliability, Professor Anne Barros (funded by DNV-GL for the first 5 years).

SFI SUBPRO is therefore a very key arena for us to continue our research in this area. Together with the industry partners, we are starting out with three sub-projects from 2015:

- Developing a safety and control philosophy that is tailor-made for subsea environment and safety challenges (2016-2019)

Postdoc: Dr. HyungJu Kim (Main supervisor: Professor Mary Ann Lundteigen. Co-supervisor: Christian Holden)

- Incorporating reliability, availability, and maintainability assessments into the design of new subsea systems (2015-2018)

Phd Candidate: Juntao Zhang (Main supervisor: Professor Mary Ann Lundteigen. Co-supervisor: Associate Professor Yiliu Liu)

- Developing new methods and models for prognostics based maintenance planning (2015-2018)

PhD Candidate: Yun Zhang (Main supervisor: Professor Anne Barros. Co-supervisor: Professor Antoine Rauzy)

- Optimizing condition-based maintenance and prognostics (2017-2020)

PhD Candidate: Himanshu Srivastav (Main supervisor: Professor Anne Barros. CO-supervisor: Professor Mary Ann Lundteigen)

The subprojects involves contributions from industry partners,2 new PhD candidates, and 1 new postdoc, in addition to Professor Mary Ann Lundteigen, Professor Anne Barros, and Associate Professor Yiliu Liu.

Main contact: Professor Mary Ann Lundteigen

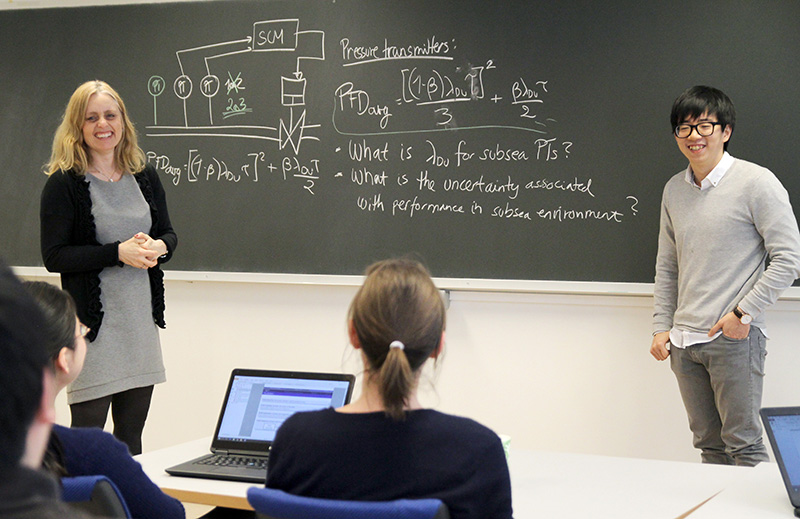

SUBPRO pictures