Aluminium activities - TEM Gemini Centre

Aluminium activities (light metals)

The study of aluminium alloy systems using TEM has been a pillar in the Trondheim TEM environment for many years.

In studies of light metal alloys there are challenges when it comes to establishing relations between the nano‐structure and the mechanical properties in for example strength and ductility. In Al‐Mg‐Si/Ge‐(Cu) alloys the hardness increase is due to precipitation of nanometre sized metastable phases that form from solid solution during heat treatment. High strength- and weight ratio and good corrosion properties is industrially relevant due to superior mechanical properties.

Several people are studying aluminium alloys at the TEM Gemini Centre. We have ongoing projects working in close collaboration with SINTEF, Hydro Aluminium and other companies producing aluminum products. TEM Gemini Centre collaborate with Hydro Bonn and two universities in Japan, University of Toyama and Tokyo Tech.

Collaboration with Japan

The collaboration within aluminium and TEM with Japanese research groups will be expanded in the years to come. In 2015 we were awarded a new international Partnership (INTPART) project.

The collaboration within aluminium and TEM with Japanese research groups will be expanded in the years to come. In 2015 we were awarded a new international Partnership (INTPART) project.

In addition to NTNU and SINTEF, Hydro, University of Toyama and Tokyo Institute of Technology are partners. The objective of this project is to continue the fruitful partnership we obtained through the earlier project, and also include and formalize educational issues as guest lecturers, workshops and joint courses.

Norwegian-Japanese aluminium alloy research and education collaboration, INTPART

Research projects

Smart 6xxx alloy development for rolling and extrusion (RolEx)

The project focuses on precipitation in extruded and rolled products with the goal of keeping/ improving properties while decreasing production costs. A set of new alloys to test out the effect of different additions in very lean 6xxx alloys have been screened.

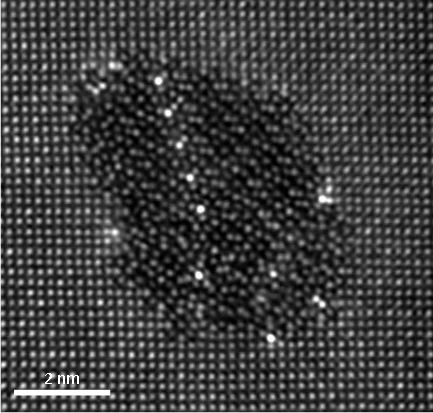

Fundamental investigations of precipitation in the solid state with focus on Al-based alloys

A project funded by the Research Council’s FRIPRO program. As a part of the project, several aluminium alloy systems have been examined for different types of precipitates. STEM images from the new ARM microscope are a main contribution to this project. HAADF STEM and precipitate-matrix strain measurements have also been conducted.

Fundamentals of intergranular corrosion in aluminium alloys (FICAL)

A five year competence (KPN) project that has the objective of establishing new fundamental understanding of the mechanisms of intergranular corrosion (IGC) susceptibility. Grain boundary segregation and connection to precipitates and corrosion properties are some of the issues being studied.

Aluminium alloys with mechanical properties and electrical conductivity at elevated temperatures (AMPERE)

A five year competence (KPN) project where Al alloys will be studied for several combined properties at elevated temperature (100°C and above), responding to the demand for a combination of high strength and high conductivity without degrading other properties such as fatigue resistance. The project aims, among other things, to provide new advances in experimental technologies.

TEM Gemini Centre involved in two SFI centres

In addition two of the SFI Centres the TEM Gemini Centre is involved in are connected to aluminium.

In the CASA project we are involved in the “lowest scale” of the multiscale activities, including TEM of precipitates, grain boundaries, precipitation free zones and interactions of them with dislocations in deformed, mostly industrial Al alloys. In the SFI Manufacturing project, joining of aluminium with other materials in multi-material products will be a central topic.

Projects ending during the last two years

- Nucleation Control (KK).

- Sustainable aluminium surface applications (SALSA).

- VITA Multiscale modelling in Aluminium (MultimodAl).

- MoReAl - competence project.

- Japanese- Norwegian Al-Mg-Si precipitation project, a bilateral competence building project.

All these projects have been jointly between NTNU and SINTEF, and supported by the Research Council of Norway, in addition, many of them were supported by Hydro Aluminium.

Contact

In the media

New Girl on the Block (15.09.2015, SFI CASA news)

Down to the atom [pdf] (10.11.2014, International Innovation)