Tours

INALCO2026

Tours

we will organise two tours on the last day of the INALCO 2026 conference. The tours run in parallel, so you can only attend one of the tours.

Photo: Vegard Thorvaldsen/Statens vegvesen

Date: Friday 12 June

Time: 12:30

Meeting point: TBA

Visit the newly opened Hangar Bridge in Trondheim, a 55-m-long and 9-m-wide all-aluminium pedestrian bridge.

This bridge is among the few aluminium bridges built in Norway over the past three decades. The bridge deck is made from 100% recycled aluminium, sourced from the dismantled offshore oil and gas platform Gyda, which was in operation in the North Sea from 1990 to 2021. More than 18,000 t of steel and other metals were cut into coarse pieces, sorted, remanufactured, and remelted, achieving a recovery rate exceeding 98%.

Aluminium was primarily used in helidecks, walkways, and equipment modules, mainly from the 5xxx and 6xxx series. The material was sent to Stena and Hydro in Sweden for shredding, sorting, remelting, DC billet casting, extrusion, and friction stir welding of bridge profiles and panels.

Furthermore, sub-assembly of the bridge sections took place at Leirvik AS in Norway before final on-site assembly. The 60-tonne structure was installed using a single crane. Parts of the bridge sections, including non-load-bearing elements, were also joined using automated laser–arc hybrid welding (LAHW). This is a novel and promising technology that improves productivity, reducing welding time by 10–20 times, while also lowering consumable use and energy demand compared with MIG welding.

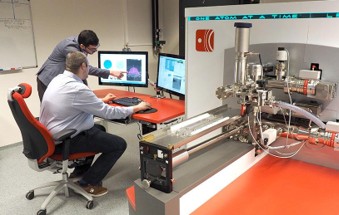

Atom Probe Tomography (APT) at Department of Materials Science and Engineering Photo: NTNU

Date: Friday 12 June

Time: 12:30

Meeting point: TBA

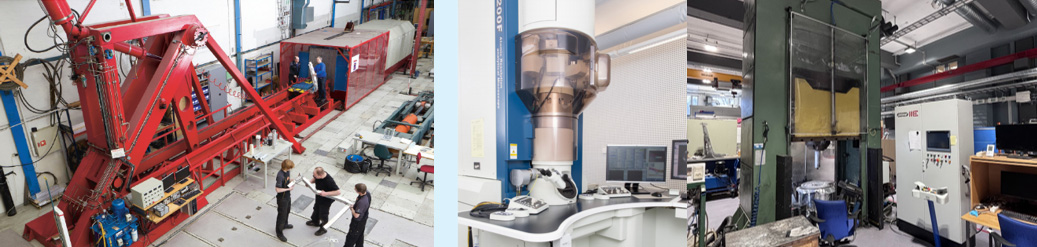

Join us for an exclusive tour of NTNU and SINTEF’s research laboratories, featuring state-of-the-art equipment for materials testing, characterization, and manufacturing. This is a rare opportunity to explore the advanced facilities and pilot‑scale installations driving cutting‑edge innovation in aluminum alloy development.

Get an inside look at our atom probe tomography and transmission electron microscopy labs, where researchers investigate materials down to the atomic scale. You will also see our comprehensive lab- to industrial-scale equipment for welding, machining, casting, extrusion, forming, and high‑strain‑rate impact testing. Guided by our experts, you'll learn about ongoing research and explore potential avenues for collaboration.

From left - 1: High‑strain‑rate impact testing at Department of Structural Engineering. 2: Aberration transmission electron microscopes (TEMs) at Department of Physics. 3: 800 tonns extrusion press at SINTEF Industry. Photo: NTNU/SINTEF