IVB - Additive Manufacturing

Laboratory for 3D printing

Laboratory for 3D printing

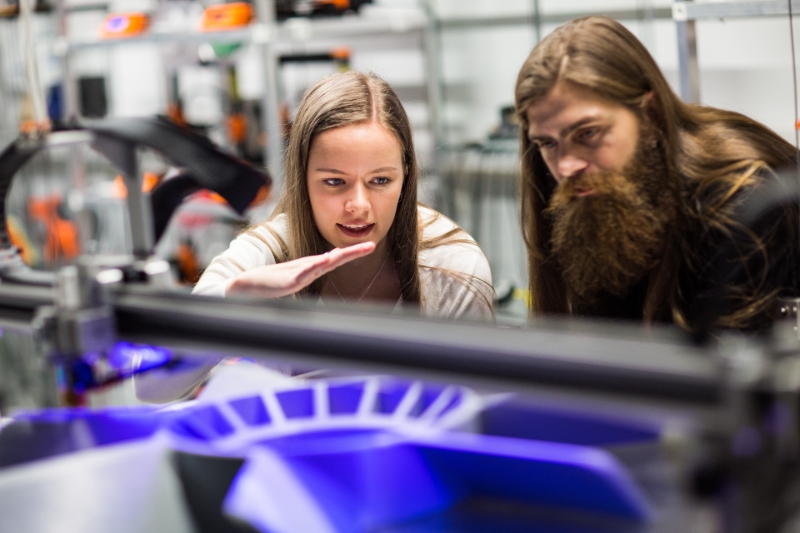

At our 3D-print lab we can manufacture components in various plastics and polymers. We use several different types of printers with various printing methods to ensure a usable and good result.

Access and opening hours

Opening hours vary – see the notices on the doors to S-113 and S-112. A student assistant will always be present during the lab's opening hours.

What can you do

The 3D Print Lab for students is deeply integrated into engineering and design study programs. It is used for prototyping, product development, and visualizing and testing individual products. To use the 3D Print Lab, you need a digital model of the object you want to produce.

Using a 3D modeling tool (SolidWorks, Autodesk Inventor, Fusion 360, Tinkercad, etc.), you can create the desired geometry, which is then "translated" into code that the 3D printers can read.

By taking a basic 3D printing course, you will gain an understanding of how selected 3D printers work and which software is used to give the digital model the desired properties.

Equipment and materials

Equipment:

The student lab in S-112 is equipped with a wide selection of desktop printers, including models from PRUSA and Phrozen.

Materials:

Printing is commonly done using PLA in various colors (a plant-based material). However, other materials such as PETG, ABS, and TPU can also be used, depending on the product's requirements. The choice of material affects properties like strength, flexibility, transparency, and weight.

Training and safety

-

Using the 3D Print Lab requires both theoretical and practical training, including HSE (Health, Safety, and Environment). For details, contact the student assistant.

Innovation and entrepreneurship

The ability to turn an idea or sketch into a physical model for functional testing creates excellent opportunities for innovation and entrepreneurship.

Previous students have used 3D printing for a variety of projects, ranging from redesigned hand orthoses to casting molds for polyurethane.