Chemical reactor research

Bio and Chemical Reactor Research

The activity on reactor engineering has been concentrated in fields directly supporting the analysis, understanding of physical processes, optimization of process performance, scale-up and design of bio and chemical reactors and phase separators. The most important research areas are:

- Mathematical modelling of bio and chemical reactors

- Multiphase flow modelling

- Direct numerical simulations of turbulence

- Development of novel numerical solution methods and algorithms

- Modelling of fluid particle coalescence and breakage

- Interactions of mass transfer, bubble hydrodynamics and complex fluid properties

- Understanding and experimental validation of numerical models by experimental investigations of phenomena:

- Single and multiphase fluid flow

- Fluid particle coalescence and breakage mechanisms

- Interfacial mass transfer in bio and chemical reactors

- Bubble hydrodynamics

- Rheology of complex fluids

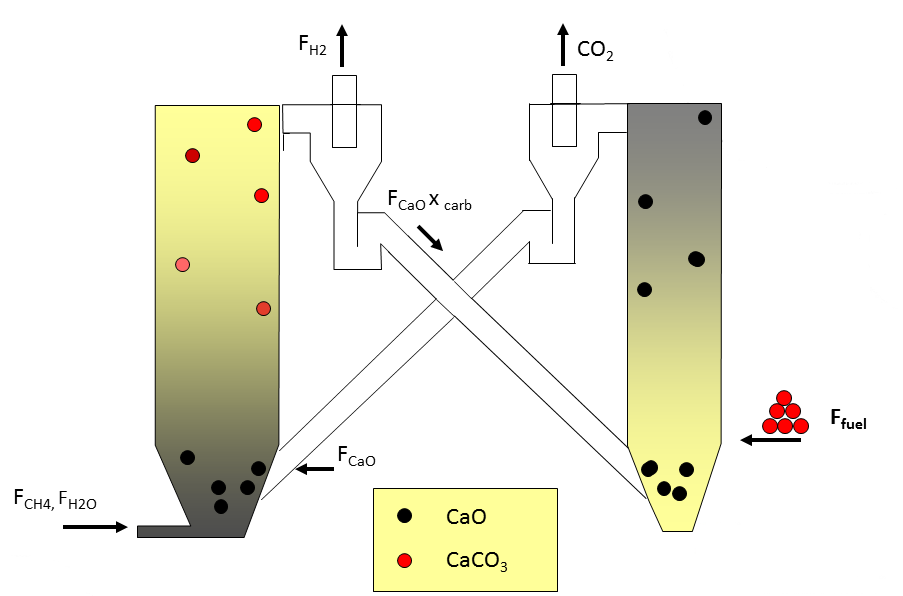

- Analysis and design of reactors for environmentally friendly bio and chemical processes

We have for more than 25 years been developing in-house computational fluid dynamics (CFD) codes for simulating multiphase flows in chemical reactors. The work in this area is focused on investigating the performance of chemical reactive systems like fixed packed bed, fluidized beds, bubble columns, airlift or draft tube and agitated tanks. The most common bioreactors are the stirred tank, the bubble column and the airlift bioreactors.

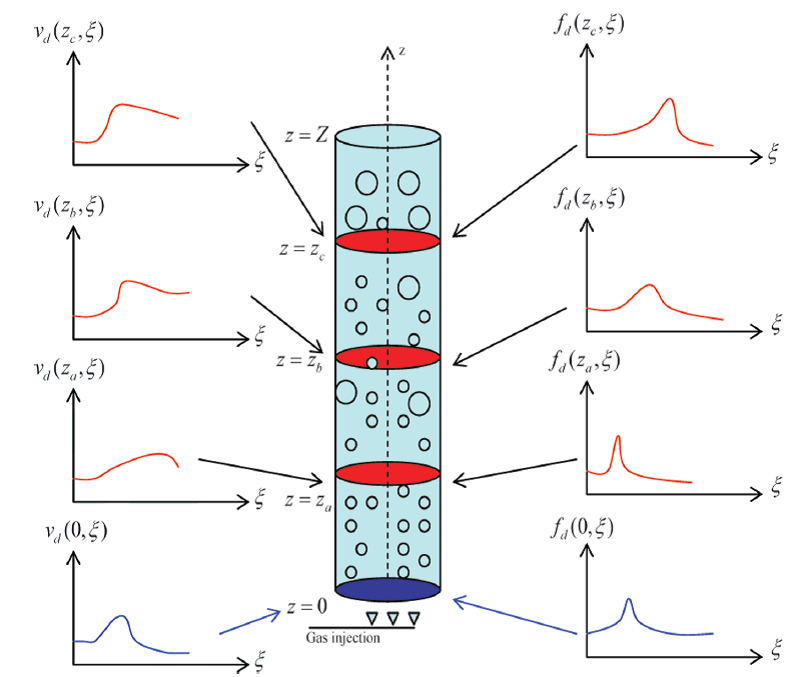

The combined multifluid-population balance model is the preferred modelling concept for multiphase bio and chemical reactors.

This research field is optimized by teamwork and excellent communication between researchers having excellent theoretical knowledge and others having excellent skills in experimental analysis and design of facilities such that a common notation is worked in the group. This also comprises statistical analysis of experimental data, model discrimination and determination of uncertainty of experimental data and model predictions.