Research - CO2 Impact Gemini Centre

Research

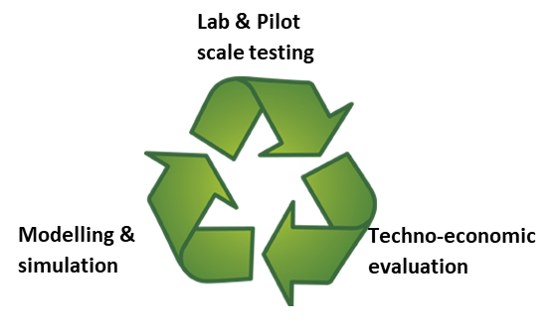

The partners have extensive experience in absorption research covering many aspects of the technology. The partners are also active in many research projects, both national and international (EU, CETP). These research projects have led to numerous publications. We have also provided some blog posts (like those linked on these pages).

We have produced an information package for the assessment of new amine solvents, summarising some of the most important topics to consider when assessing the stability of a new solvent for post-combustion CO2 capture.

Ongoing research activities

Development of economically and environmentally favorable absorbent systems

- Screening apparatus – experimental testing of a large number of chemicals

- Molecular simulation

- Combined H2S and dehydration

Establishing basic models

- Thermodynamic models

- Kinetic models

- Effective gas/liquid contact area

- Degradation model

Studies of environmental impacts of the technology

- Degradation chemistry

- General ecotoxicology and biodegradation

- QSPR/QSAR methodology

Process monitoring

- Emission measurements from the gas phase (both offline and online)

- Online monitoring of process (liquid and gas phase)

- Measurement of mist

Experimental characterization of absorbents and packing materials

- LP and HP vapour-liquid equilibrium

- Kinetics

- Thermal properties

- Transport properties

- Solvent degradation and corrosion

Validation of models for absorption and desorption

- Pilot rigs (flexible flue gas based on propane gas, biomass, and coal)

- Testing rig for packing materials, liquid distribution, effective contact area etc.

Modeling and optimization of full-scale plants

- Using both commercial tools like Aspen Plus, Hysys and in-house process simulator, CO2SIM, rate-based rigorous models of the absorber, desorber, membrane-contactor and whole plants

- Dynamic modeling and advanced process control

- Modelling of mist particles

Techno-Economic Analysis (TEA) of industrial plants

- Benchmarking of solvent systems and absorption-based processes

- In-house tool for CAPEX and OPEX calculations

Projects and Centers

Gemini members are part of several research projects. Some examples are given below:

- AURORA focusing on the CESAR1 solvent blend

- FME gigaCCS is a Norwegian CCS research center

- MISSION-CCS is an EU doctoral networ

- REALISE demonstrates a refinery-adapted cluster-integrated strategy to enable full-chain CCUS implementation.

- LAUNCH focuses on understanding and controlling degradation.

- ALIGN-CCUS interlinked carbon capture, utilisation and storage research with the goal of transforming industrial regions into economically robust, low-carbon centres.

- FME NCCS is large Norwegian CCS research center.

Contact

Professor, NTNU

E-mail: hanna.knuutila@ntnu.no

Research Manager,

SINTEF Industry

E-mail: Eirik.Silva@sintef.no

Professor, USN

E-mail: Lars.Oi@usn.no