WP2

Work Package 2: Casting Processes

Work Package 2: Casting Processes

Main research questions:

RQ2.1: How will a wider range of elements affect castability and product quality for different casting processes?

RQ2.2: How can casting defects be minimised by adjusting alloys and processes?

RQ2.3: How can conventional alloy limits be challenged while maintaining castability and properties?

RQ2.4: How can numerical modelling assist in reducing casting defects and improve process control and product properties (input to FAST Virtual Lab)?

Approach and methodology:

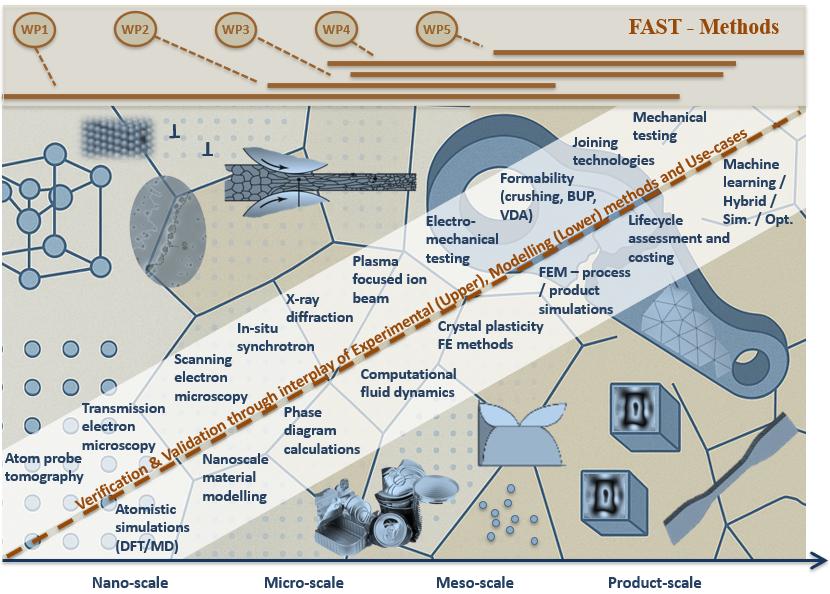

Thermodynamic approach, coupled with microstructure models, to evaluate alloy compositions and effects of scrap on the microstructure, castability, and final properties. Process model tools will be used to predict casting defects and process optimization ranges - combines with lab-scale experiments for solidification and castability (see figure).

Research tasks:

T2.1. This task will explore the capability of state-of-the-art microstructure modelling tools, in-house codes, commercial thermodynamic software codes, and open-source software to predict microstructural features like solid solution levels, amount and type of intermetallic phases and the size distributions of hardening particles after casting and heat treatments of alloys with PCS content. These models are verified from conventional alloys and need to be developed and validated for PCS-based alloys.

T2.2: Defect formation in continuous casting processes (e.g. hot-tearing and macro-segregation) will be studied, by process modelling, to reveal the effect of PCS on the alloy defect susceptibility.

T2.3: This task focuses on understanding the effect of impurities on the near-net shape HPDC process. Models linking the metallurgical microstructure features predicted by the microstructure models to predictions of alloy properties (e.g. properties and conductivity) will be developed for rapid screening of effects of impurities on HPDC alloys. To predict the grain-structure (morphology, size and density), meso-scale modelling approaches like cellular automation will be developed, process simulations with FEM software will be used to link alloy, process and cast product quality. Thermal histories from simulations will be used to study the microstructure at different locations in the castings. The model development will be accompanied with in-situ X-ray tomography, diffraction or laminography of cast components during mechanical testing.

Main expected outcomes:

OU2.1: Thorough understanding of the complex interdependence of composition-castability-microstructure-property relationships that are essential for achieving defect free castings of recycled alloys.

OU2.2: Mitigation strategies that include exploring and adjusting alloy compositions and modifying process conditions.

OU2.3: 3 PhD candidates are connected to WP2.