WP4: Joining Processes

WP4: Joining Processes

WP4: Joining Processes

Main research questions:

RQ4.1: Is the weldability and joinability (such as defect formation or HAZ softening) of aluminium affected by increased PCS content and how does it affect the resulting properties (strength, ductility and fatigue)?

RQ4.2: How can numerical modelling assist the development of innovative welding/joining processes with minimal susceptibility to welding defects and optimal mechanical performance?

RQ4.3: How to predict joint performance with regards to welding parameters and PCS content?

RQ4.4: To which extent can novel joining methods be developed to enable repair and disassembly of aluminium structures?

RQ4.5: How to develop advanced joining and solid-state additive manufacturing (AM) processes for efficient production of structures/components?

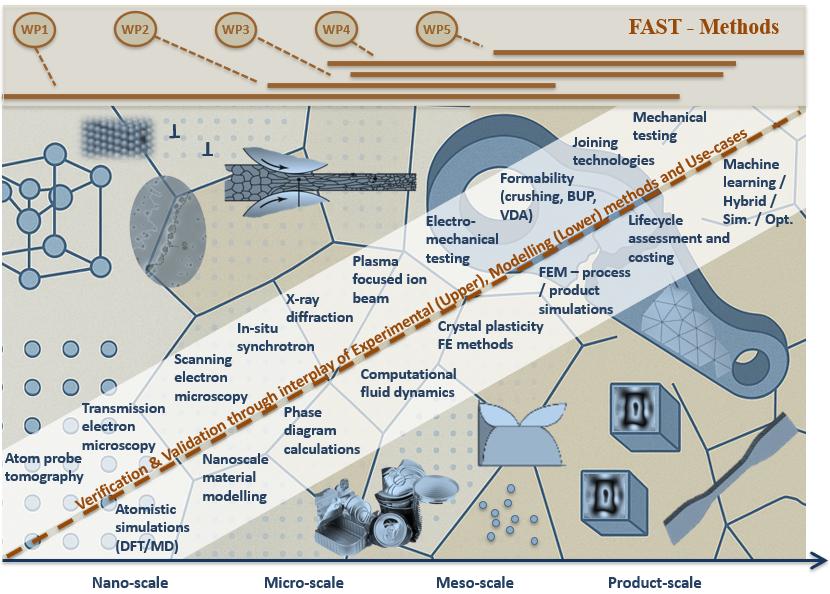

Approach and methodology: Establish the joining-microstructure-properties and performance relationship through experimental and numerical investigations and depending on joining process apply methods such as computational fluid dynamics, X-ray tracing, material point methods, microstructure models to support welding/joining process development and optimization. Property predictions will be explored by combining experimental data on thermomechanical history with numerical models as well as data-driven and in-situ models – to understand the underlying physics and explore mitigation strategies for welding of PCS aluminium (see figure).

Research Tasks:

T4.1: This task aims to develop novel joining and welding technologies to achieve zero-defect, high-quality welds. It includes exploring the suitability of advanced techniques such as, but not limited to oscillating LBW, laser-assisted FSW and HYB on PCS. The use of local post-welding heat treatments to manipulate the microstructure and correspondingly manipulate and increase the resulting properties (fatigue, corrosion, strength) will also be explored. Benchmarking will be made to well-established welding processes.

T4.2: A multi-scale modelling approach will be developed to enable virtual optimization of the joining processes and performance prediction of welded structures across both micro- and macro-scales. This approach will support process parameter optimization to minimise defects and provide foundation for adaptive control when coupled with in-line sensors and data-capturing. Microstructural models, capturing phenomena such as grain structure evolution and precipitate formation will be integrated with process simulations. These coupled numerical models will predict the properties and possible defects and performance based on the alloy composition and welding process.

T4.3: Explore how to employ data and in-depth knowledge about the welded and joint structures, in design optimization, while also enabling reuse, refurbishment or repair. The design space for welding and joining of PCS aluminium will be mapped, optimised and benchmarked for strength, fatigue, minimised distortion, environmental resilience and ease of disassembly. Task will build on the established data foundation and modelling tools of T4.1 and T4.2.

T4.4: Develop joining-based technologies for repair and refurbishment of aluminium structures for increased lifetime of components, or local strengthening of weak regions, using techniques such as FSW, HYB and FSW-AM. The work also includes strategies for disassembly.

Main expected outcomes:

OU4.1: Provide modules for FAST Virtual Lab to predict the behaviour of PCS alloys on weldability and joint performance.

OU4.2: New model framework that couple models along scales for supporting design optimization and adaptive process control.

OU4.3: Develop novel joining and welding processes that tolerate high PCS content, and a design strategy for enabling dis-assembly, repair, reuse and recycling.

OU4.4: 3 PhD candidates are connected to WP4.