WP1

Work Package 1: Material Properties

Main research questions:

RQ1.1 - What are the effects of PCS on critical properties like strength, ductility, fatigue, corrosion and conductivity?

RQ1.2 - Which accumulated element, or combination of elements, are responsible for the property changes, and at what critical concentrations?

RQ1.3 - What are the changes in microstructure caused by the altered alloy chemistry, and how do this relate to the thermo-mechanical process?

RQ1.4 - How can we integrate advanced experimental techniques and numerical methods to better understand and mitigate the effects of PCS?

RQ1.5 - How can FAST Virtual Lab be capable of predicting the relevant properties of PCS alloys solely based on checmical composition and thermo-mechanical history?

Approach and methodology:

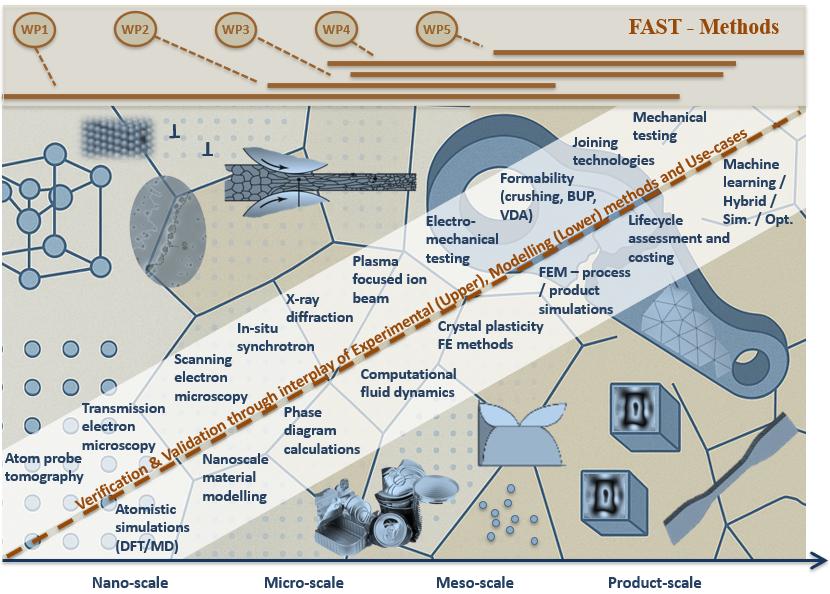

A multi-physics approach across material scales from the nanoscale up to meso-scale, integrating both experimental and simulation methods (see figure below). This includes TEM and SEM measurements, X-ray tomography, and mechanical tests (both ex-situ and in-situ) combined with numerical methods ranging from DFT/MD to CPFEM analyses of relevant microstructural features.

Research tasks:

T1.1 - Experimental investigations will quantify how varying fractions of PCS affect yield strength, ultimate tensile strength, and work-hardening in selected aluminium alloys. Based on these investigations, we will develop a Strength module for the virtual laboratory. This module will predict relevant properties using the chemical composition and thermo-mechanical history of the alloy as input.

T1.2 - Numerical methods will be developed to predict crack initiation and propagation in HPDC and wrought alloys. Additionally, we will create a Ductility module for the virtual laboratory, which will predict the ductility of an alloy based solely on its microstructure.

T1.3 - This task will map the effect of PCS on fatigue performance and corrosion resistance for selected alloys by combining advanced microscopy and lower-scale simulations. Mitigation techniques will be proposed and applied to these alloys. Finally, an evidence-based Durability module for the virtual lab will be developed.

T1.4 - We will quantify how PCS alters electrical conductivity in relevant alloys. A Conductivity module for the virtual lab will be developed.

Main expected outcomes:

OU1.1 - Identification of properties of high PCS content alloys, and their effects, across relevant length- and timescales.

OU1.2 - Physics-based and data-driven digital toolkits capable of predicting critical properties (input Virtual Lab).

OU1.3 - PhD candidates are connected to WP1.