WP3

WP3: Forming Processes

WP3: Forming Processes

Main research questions:

RQ3.1: How does texture, impurity-driven microstructure and heterogeneities change during thermomechanical treatments and how can these changes be accurately predicted or controlled?

RQ3.2: Can in-situ real-time diffraction techniques be successfully applied to a prototype of an extrusion process and reveal fast occurring phase transformations as the recrystallization?

RQ3.3: How can in-line measurements, advanced forming simulations, and data-driven process optimization be configured to control novel and advanced forming processes and the PCS-based component’s microstructure evolution?

Approach and methodology:

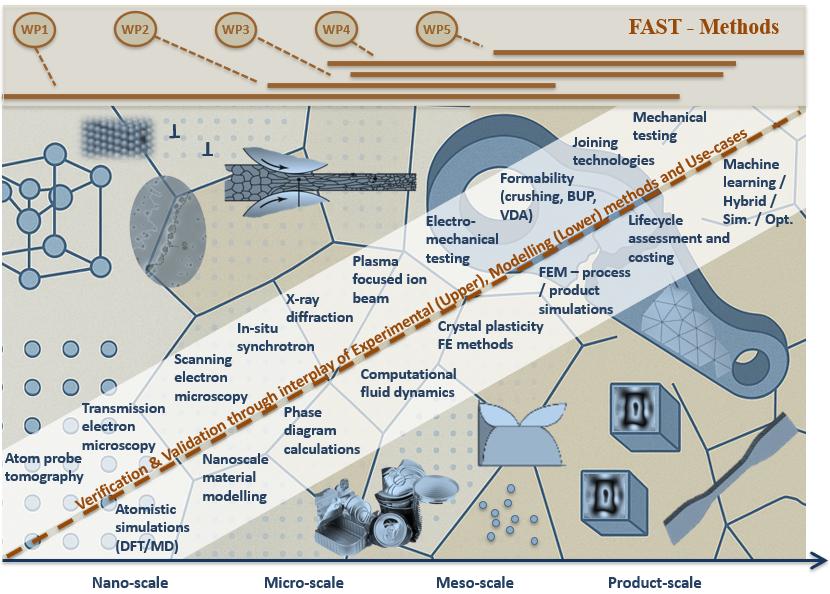

Simulation tools and models, across multiple material scales, including physics-based models predicting essential microstructural changes and texture evolution during plastic deformation. Continuum plasticity-based FEM analysis will be employed at product scale. ML methods will create surrogate representations enabling seamless integration into higher-scale simulations (see figure).

Research tasks:

T3.1: This task will explore advanced forming and microstructure modelling of aluminium components based on PCS. Develop integrated experimental and simulation approaches for hot forming of PCS-aluminium - focusing on texture evolution, plastic anisotropy, and to model microstructure evolution including recrystallization, the role of intermetallics, and precipitates, supported by thermodynamic and kinetic databases. Create surrogate models for FE integration, enabling efficient simulations of complex and novel forming processes with industrial relevance.

T3.2: We will apply in-situ/operando time-resolved synchrotron diffraction study to analyse microstructural changes at the extruder nozzle. We will develop a custom apparatus and software for time-resolved measurements to capture recrystallization in real-time and conduct post-mortem TEM for validation.

T3.3: We aim to study hetero-structured PCS-based aluminium alloys and engineer intermetallic phases to create beneficial heterostructures. Further, utilise strain-gradient CPFEM to model heterostructures incl. grain boundary and PFZs and characterise strength-ductility via mechanical testing and digital image correlation.

T3.4: Adaptive control system for in-line and real-time 3D bending process, developing sensor feedback system for digital twin of bending operations. Applying ML surrogates trained on continuum FEM results, predicting spring-back and improved dimensional accuracy.

Main expected outcomes:

OU3.1: Provide formability and texture modules for the FAST Virtual Lab to understand and predict the behaviour of PCS-based alloys during forming,

OU3.2: Extensive experimental results and prototypes of forming processes with adapted thermo-mechanical routes that are designed for high-quality PCS-based products.

OU3.3: 5 PhD candidates are connected to WP3.