Laboratory for Mechanical Testing

Fatigue, Fracture and Mechanical Characterization Laboratory

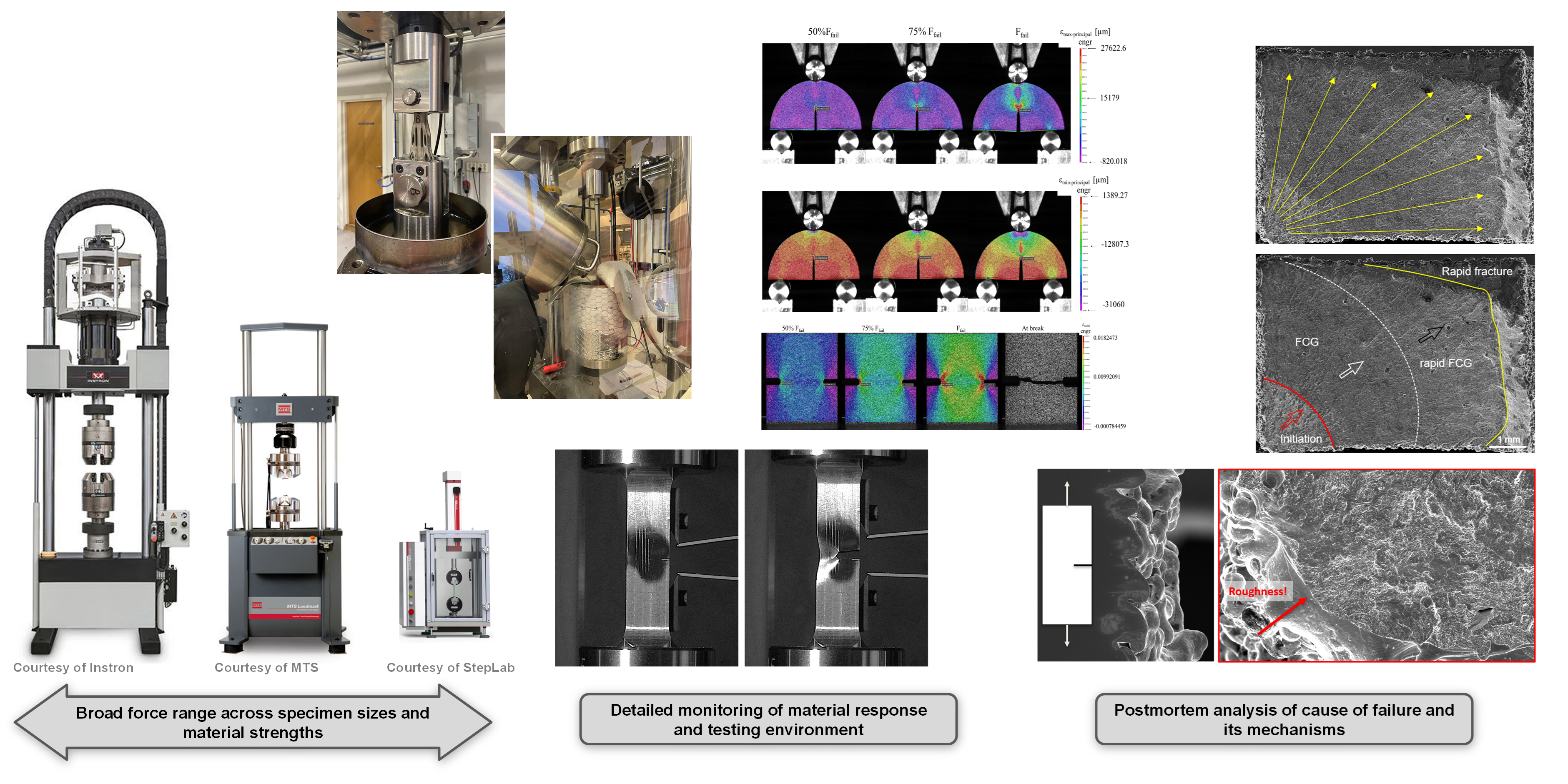

The laboratory supports experimental mechanical characterization, with particular emphasis on fatigue and fracture behaviour, damage evolution, and durability of metallic and non-metallic materials. Testing covers uniaxial, multiaxial, and rotating-bending loading, as well as other monotonic and cyclic loading modes relevant to structural integrity and performance. Experiments can be conducted under controlled environmental conditions, including elevated and low temperatures, using multiple integrated environmental chambers. Strong emphasis is placed on high-quality load, strain, and response monitoring to support detailed analysis of material behaviour beyond end-of-life metrics.

Testing capabilities

- Mechanical characterization under monotonic and cyclic loading

- Uniaxial fatigue testing (low cycle fatigue and high cycle fatigue)

- Multiaxial fatigue testing (combined tension/compression and torque)

- Rotating bending fatigue testing

- Fatigue testing at elevated and low temperatures

- Fracture and failure testing under monotonic and cyclic loading

- Slow strain rate (SSRT), constant load (CL), and low-cycle fatigue testing in autoclave environments for stress corrosion cracking and hydrogen embrittlement studies

- In-situ mechanical testing combined with SEM and X-ray computed tomography (XCT)

Monitoring and control

Experiments are conducted using servo-hydraulic and electromechanical test systems with closed-loop control in load and strain. Monitoring capabilities include:

- High-resolution load and displacement measurement

- Axial and torsional extensometry

- Synchronized data acquisition for force, torque, displacement, and strain

- Monitoring of stiffness degradation and cyclic response evolution

- Environmental monitoring during temperature-controlled testing

Laboratory equipment

Universal testing machines:

- Multiaxial Instron® 250 kN / ±2000 Nm (servo-hydraulic with hydraulic grips)

- Instron® 100 kN (servo-hydraulic with hydraulic grips)

- Instron® 50 kN (servo-hydraulic with hydraulic grips)

- Multiaxial MTS® 100 kN / ±1100 Nm (servo-hydraulic with hydraulic grips)

- MTS® 50 kN (servo-hydraulic with hydraulic grips)

- MTS® desktop 5 kN (electromechanical with manual grips)

- Five portable Ametek® CS2 1 kN systems (education purposes)

- Cormet® SSRT 50 kN (electromechanical with manual grips) †

- Cormet® SSRT 25 kN (electromechanical with manual grips) †

- Kammrath x Weiss® tensile/compression stage 5 kN (in-situ SEM testing) ‡

- Bruker® MTS2 tensile/compression stage 440 N (in-situ XCT testing) ‡

High-frequency fatigue test machines:

- Instron® 10 kN (electrodynamic with pneumatic grips)

- Multiaxial StepLab® 20 kN / ±140 Nm (electromechanical with pneumatic grips)

- StepLab® 10 kN (electromechanical with pneumatic grips)

- StepLab® 2 kN (electromechanical with pneumatic grips)

- Zwick® ARBM120 rotary bending machine

Temperature chambers:

- Instron® model 1706A, up to 1400°C

- Instron® model 3119, -150°C to +400°C

- Zwick®, -80°C to +850°C

- MTS®, -150°C to +450°C

Monitoring tools:

- High-performance infrared camera (TELOPS® TS-IR MW)

- Digital Image Correlation (DIC) systems (Correlated Solution® VIC-2D and VIC-3D)

- Ultra-high speed camera (Photron® FASTCAM SA-Z)

- High speed camera (Photron® FASTCAM SA3)

- Digital machine-vision cameras (Allied Vision Stingray® F-504B)

- Acoustic emission monitoring system

- Electrical potential drop measurement system

Specialized testing and conditioning systems:

- Zwick® BUP600 (sheet metal formability testing machine)

- GABO Qualimeter Eplexor® 150 N (low-force dynamic mechanical testing)

- Memmert® HPP1400 (stability/constant climate chamber)

† autoclave compatible, located at Metallography Laboratory

‡ located at Nanomechanical Testing Laboratory