RA 2: Scale and process bridging methodologies - SFI PhysMet

Scale and process bridging methodologies

– Research area 2

Objectives

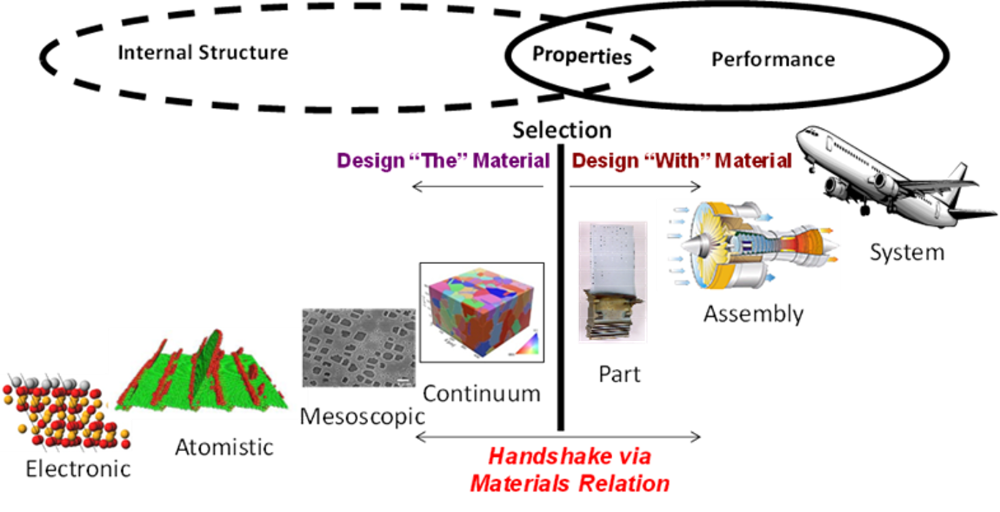

- Provide fundamental material data and understanding through high-throughput calculations and simulations from atomistic to microstructure scale.

- Develop and validate specific models for alloy recycling, AM and innovative processing.

- Establish and validate multiscale and multi process modelling framework and AI methods, providing smart design and developing tools of innovative alloys and products.

Approach and methodology

- Atomic scale modelling: Density functional theory (DFT), molecular dynamics (MD) and kinetic Monte Carlo (KMC) approaches.

- Microstructure and process model: further development and coupling of existing microstructure simulation models, including solidification, heat treatment, recrystallization, working hardening, crystal plasticity, and so on.

- AI tools: Machine learning tools for data mining, data analysis and optimization of processing parameters and chemistry.

- Combination of the through process modelling tools with AI approaches.

Challenges

- How to reach a deeper understanding on the mechanisms and kinetics behind the physical metallurgical phenomena down to atomic scales:

- How to realise computational engineering based smart design of alloys and products with tailored properties.

- How to realise digitalization and automatization of the production in physical metallurgical industry.