Infrastructure on Hydropower - NTNU Energy Team Hydropower - NTNU Energy

Infrastructure on hydropower

Hydraulic lab

The hydraulic laboratory holds an area of 3000 m2 – of which 2000 m2 can be utilised for custom built hydraulic models. Serving both an educational purpose and providing opportunities for academic research, as well as commercial research with clients across the world. State of the art models are made in-house, as the lab boasts a competent machining shop and a separate workshop for woodwork and plastics.

There are three permanent flumes installed, including a tilting flume for steep slope simulation and sediment research. The laboratory is highly flexible and serves all manners of hydraulic research, such as sediment transport, flow analysis, slope stability, hydropower structures and studies in hydropower dynamics.

Geology lab

Most hydropower projects have long waterways consisting of tunnels, shafts and underground caverns. Rock and tunnel engineering remains a central aspect in design of hydropower systems. For over a century, NTNU and Norway have successfully developed cost-effective and optimal design principals and methods for hydropower, infrastructure and use of underground space.

The Department of Geoscience and Petroleum at NTNU features a state-of-art engineering geology and tunneling laboratory. The lab includes all necessary equipment, including unique test rigs for drillability, recognized by the international community within rock and tunnel engineering, and the strongest available triaxial test equipment for highly competent and hard rocks. The tests performed at this laboratory are conducted on rock samples from all around the world, spanning more than sixty countries.

National Smart Grid Laboratory

The Smart Grid Laboratory is a system oriented laboratory providing state-of-the-art infrastructure for R&D, demonstration, verification, and testing over a wide range of Smart grid use cases.

Water power laboratory

The waterpower laboratory at NTNU combines more than 100 years of experience, with modern facilities unique for Europe. The laboratory has played a leading role in the development of global hydropower, particularly with regards to designing effective hydraulic turbines.

The lab offers many possibilities for fluid dynamic research, including test rigs for both Pelton, Francis and pump turbines, with opportunity for testing at over 100m of head. Both Master-students, PhD-candidates, post-docs and international scientists are working on projects here.

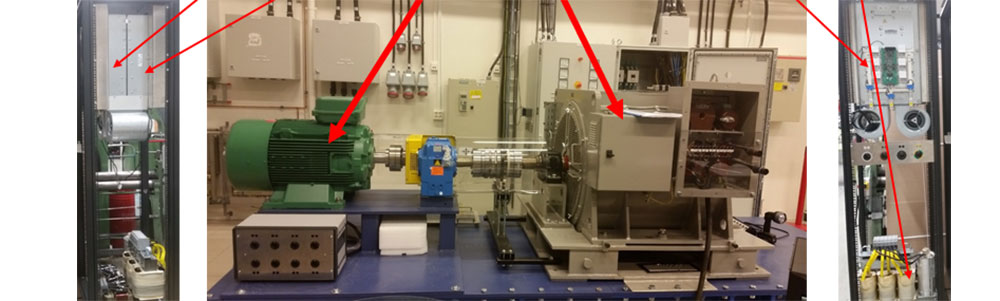

Hydroelectric power laboratory

As part of the HydroCen project, the Electric Power Laboratories is extended with a new test setup dedicated to hydropower, located within the NTNU Smartgrid laboratory. The test makes it possible to have test setups comprising of a mix of real-time emulated waterways and turbine, real physical synchronous generator and including variable speed operation in combination with real and emulated power grid. The setup is made for variable speed pumped hydro power using a converter-fed synchronous generator, but it is possible to bypass the variable speed for study of traditional fixed speed Hydropower as well. There is an on-going work to connect the generator in the electric power lab to the turbine in the Waterpower Laboratory. Thus the to two test facilities will run as twins.

The tailormade synchronous generator can be modified to have different types of faults (electric, magnetic and mechanic). This is used for developing fault detection systems. The total test setup comprises two AC-AC frequency converters, a 100 kVA induction motor and a 100 kVA synchronous machine.