Circular Economy and Resources - Industrial Ecology Programme (IndEcol)

Circular Economy and Resources

We address resources, materials, recycling and environment under different scenarios for material demand for products and capital infrastructure.

Contact

-

Helge Brattebø Professor Emeritus

+47-73594744 +4795022976 helge.brattebo@ntnu.no Department of Energy and Process Engineering -

Daniel Beat Müller Professor, Industrial Ecology Programme

+4791897755 daniel.mueller@ntnu.no Department of Energy and Process Engineering -

Johan Berg Pettersen Associate Professor, Industrial Ecology Programme

+4793809682 johan.berg.pettersen@ntnu.no Department of Energy and Process Engineering

The aluminium industry aims to promote a wider understanding of its activities and demonstrate both its responsibility in producing the metal and the potential benefits to be realized through their use in sustainable applications and through recycling.

FME ZeMe developes the fundamental knowledge and technologies needed by the Norwegian metallurgical industry to become climate neutral by 2050. Funded by NRC.

FOSIMO - "Forskningsbaserte sirkulære forretningsmodeller"

FoSiMo tackles the untapped potential of residual resources in Norway’s agriculture, forestry, and aquaculture sectors by developing research-based circular business models. The project bridges gaps between industries, enabling seamless collaboration to transform waste into value, driving sustainability, efficiency, and new economic opportunities.

To facilitate the transition to a circular bioeconomy in Norway through a strategic decision tool that enables policy makers, businesses, and civil society to coordinate actions for balancing employment, climate change mitigation, and resource use. Funding by RCN, 2020-2026

circWOOD will investigate aspects of wood use in the Norwegian economy, with particular emphasis on the reuse of wood in construction projects, and recycled wood as raw material in today's wood industry. 2022-2026

WoodStock develops climate-smart solutions and strategies to increase the use of wood, including underutilised wood resources, in the European construction sector. Funded by the European Union (Horizon Europe project), 2024-2028.

The Circular City project is an interdisciplinary collaboration to better understand the role of existing buildings as a resource base for a future circular economy. Specifically, the project aims to develop the necessary quantified models, qualitative approaches, domain knowledge and methods to develop a Circular City Information Infrastructure (CCII) that details the quantities, qualities and potential of materials and building elements at a large scale.

Hydrogen technologies for decarbonization of industrial heating processes HyInHeat helps to accelerate the transition to a more sustainable and decarbonized energy future.

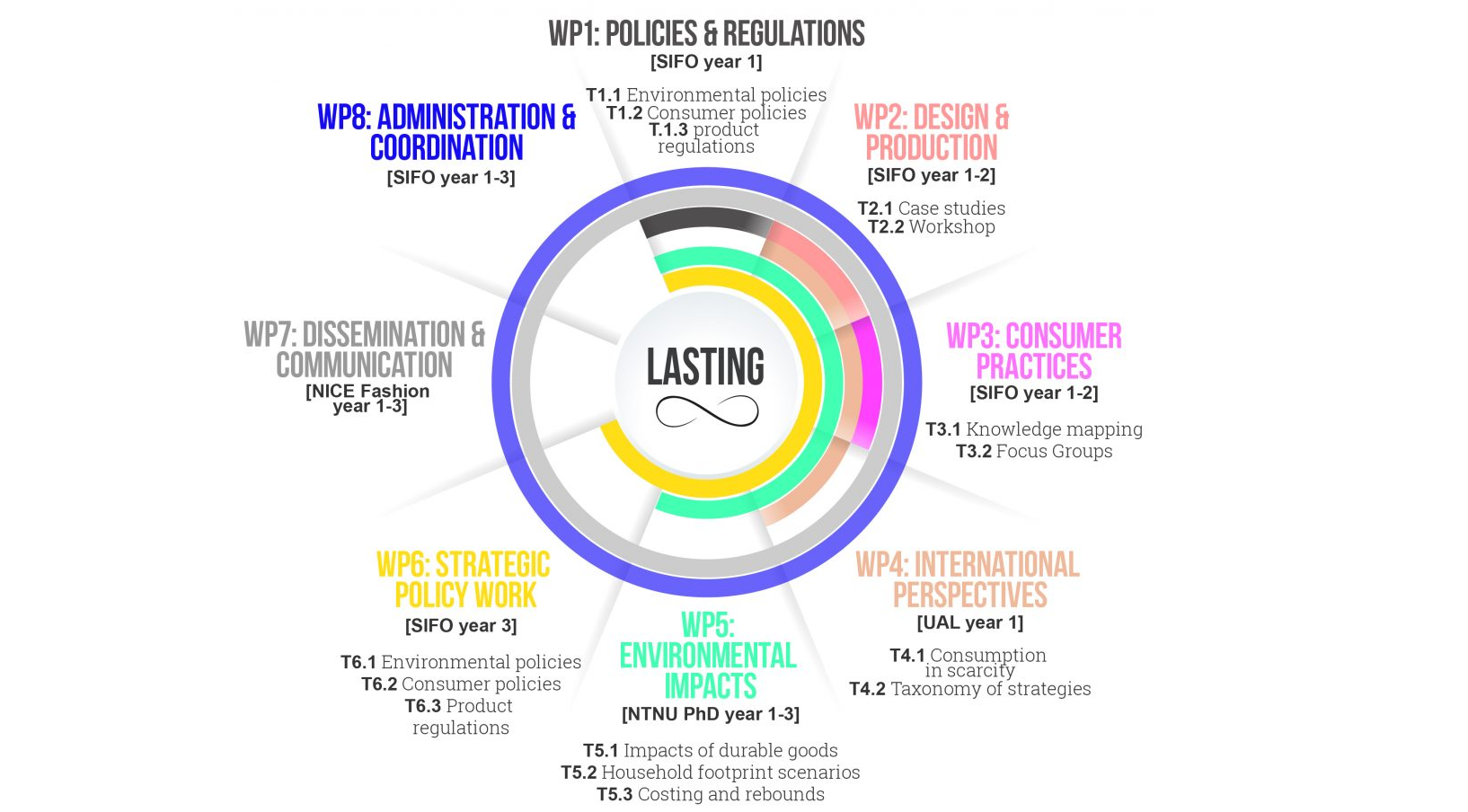

The LASTING project works with sustainable prosperity thought product durability.