COVID-19 test

NTNU's COVID-19 test: From basic research to innovation

Based on knowledge built up over years of solid basic research, the researchers developed a new and effective test method for COVID-19 within a few weeks. In addition to academic excellence, interdisciplinary collaboration was an important key to success.

Why NTNU developed a new test method

In the beginning of the coronavirus pandemic in spring 2020, there was quickly a great demand for COVID-19 tests. These were absolutely necessary in the authorities' TISK strategy (Testing, Isolation, Tracking and Quarantine). The strategy was in line with WHO recommendations.

After a short period of intensive corona testing, St. Olav's hospital in Trondheim was one of the players in the Norwegian healthcare system that was about to run out of test equipment.

There was one bottleneck in particular that created an obstacle to getting many people tested. The bottleneck was reagents (chemical solution) to isolate the genetic material from the coronavirus in samples from patients.

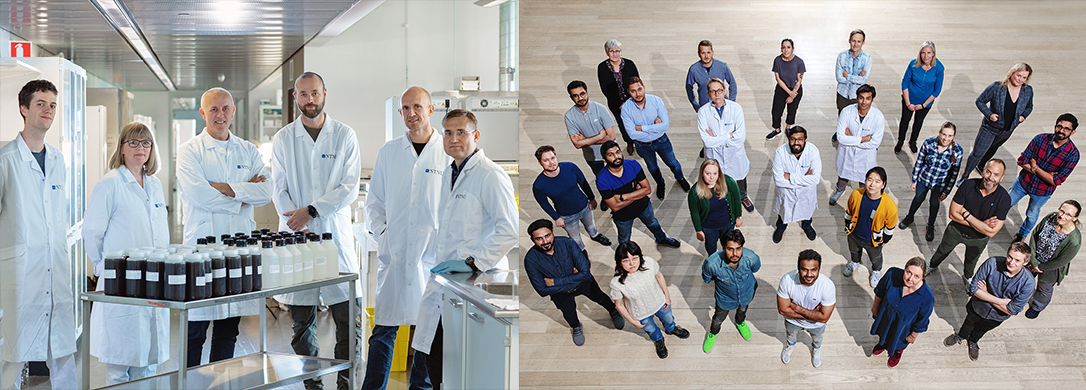

Already on 21 March 2020, St. Olav's hospital contacted NTNU to ask if NTNU researchers could develop reagents. Professor Magnar Bjørås at the Department of Clinical and Molecular Medicine and his research group quickly decided to try.

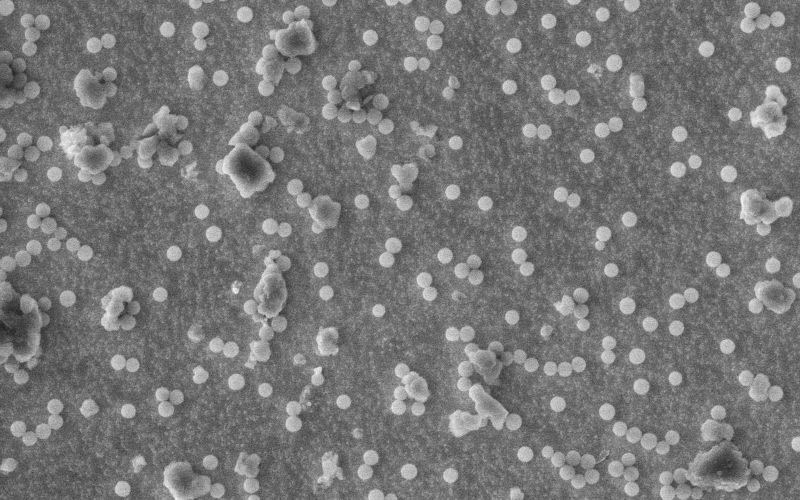

They had much of the knowledge they needed, but to succeed they also needed magnetic particles that can capture RNA, the virus's genetic material.

Associate Professor Sulalit Bandyopadhyay and colleagues at the Department of Chemical Engineering have been researching on magnetic nanoparticles for years. Bjørås' network knew about this work and made contact.

Eight days later, the two research communities had jointly developed a corona test technology that worked at least as well as the commercial tests.

From the laboratory bench to industrial production

While the researchers were able to produce COVID-19 tests on a laboratory scale, establish a manufacturing line capable of producing thousands of tests a week would take time.

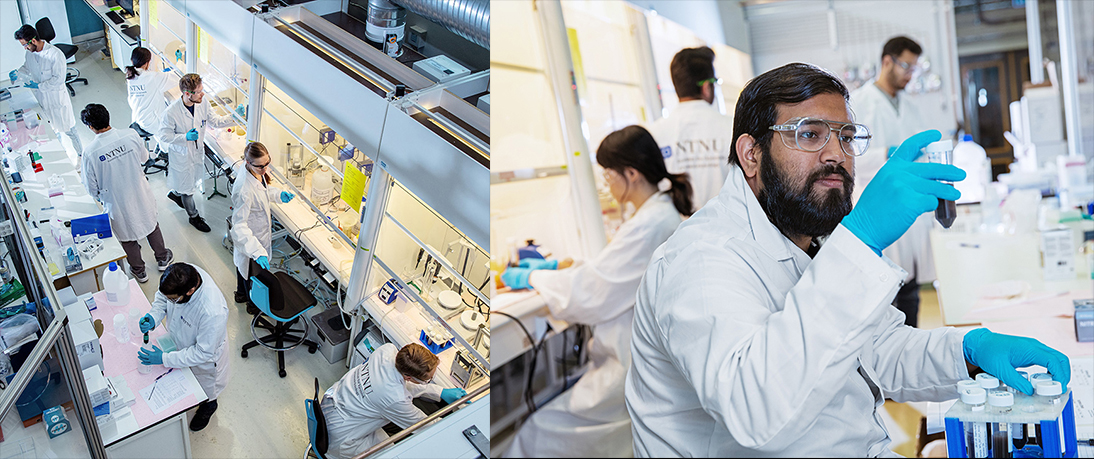

At the NTNU's Department of Chemical Engineering, two laboratories were established for the production of magnetic nanoparticles. Here, the Glass Blowing Workshop and Fine Mechanics Workshop at NTNU contributed by designing and making special equipment.

An instrument laboratory was established to check and ensure the quality of the particles before sending them to the Department of Clinical and Molecular Medicine. In this laboratory, the particles were added to the chemical solution produced.

For several months, researchers and technicians from NTNU and from St. Olav's hospital worked on the production of millions of tests.

NTNU’s COVID-19 test was exported to several other countries during the pandemic, including Denmark, India, Nepal, and Brazil.

Established the innovation company Lybe Scientific

Lybe Scientific further develops and commercializes test technologies that can be used in the diagnostics of various types of viruses – not only in humans, but also in fish farming.

The procedure, which is based on magnetic nanoparticles and an optimized nucleic acid extraction, is robust, reliable and simple. It provides high-quality nucleic acids in just 14 minutes.

Due to its simplicity and low cost, implementation of this technology to diagnose viral infections will be beneficial to the healthcare system in many countries.

Continuation of academic research activities

In addition to establish a spin-off company, it has been important to continue the research into, among other things, nanoparticles.

At the Department of Chemical Engineering a research center called the Particle Engineering Center was established in 2021. The center is led by Associate Professor Sulalit Bandyopadhyay, and one of the research areas is nanomedicine.

Honors

The Research Council of Norway's Innovation Award

Professor Magnar Bjørås and Associate Professor Sulalit Bandyopadhyay were awarded the The Research Council of Noray's Innovation Award (in Norwegian) in 2021.

NTNU employee award

Bjørås and Bandyopadhyay received the NTNU employee award the same year for Innovation and collaboration with working life.

The faculty's innovation award

At the Faculty of Natural Sciences Sulalit Bandyopadhyay's research group received the innovation award Innovator of the Year at NV 2021.

Video on YouTube with the research group that was awarded the innovation prize.

Posten's corona stamp

Posten's stamp series Research, Innovation and Technology launched the corona stamp Bionanotechnology for COVID-19 diagnostics in collaboration with The Research Council of Norway in 2023.

How does the NTNU's COVID-19 test work?

Video at YouTube.

Samples taken from the nose and throat are mixed with a chemical solution that dissolves the virus so that the virus's RNA (genetic material) is released.

The RNA molecule represents the genetic material in the coronavirus. The RNA molecules are well protected inside the virus and closely surrounded by other molecules. The first challenge is to "unpack" the virus's RNA for analysis.

NTNU therefore developed a specific combination of polar solvents, buffers, salts and other chemicals to achieve this without damaging the RNA molecule itself. Optimizing this combination is part of the NTNU innovation and contributes to being able to extract RNA from a small amount of virus.

Once the RNA molecules have been liberated from the virus, they must be extracted from the solution for analysis.

This is done by adding magnetic nanoparticles of iron oxide covered with a specific material with a high binding capacity to RNA. Then, the magnetic nanoparticles, which have linked to the RNA, can be removed from the the solution using a magnet.

The RNA is then released from the nanoparticles by adding water.

A standard PCR analysis will clarify whether the sample contains RNA from the coronavirus.

Department of Clinical and Molecular Medicine

Department of Chemical Engineering

Department of Medical Microbiology, St. Olavs hospital

NTNU Technology Transfer (TTO) and Lybe Scientific

Innovation of the technology for the OVID-19 test was patented in collaboration with NTNU Technology Transfer (TTO).

Lybe Scientific was established in 2021. The company further develops and commercializes the test technology.