Battery Materials - FACET

Battery Materials

FACETs work on battery materials is dedicated to design novel materials for Li-ion batteries and beyond Li-ion battery technologies and to tackle on the key challenges in realizing the next generation energy storage devices. We focus on Gen4a, Gen4b, and Gen5 batteries comprising Li metal or Si anodes in combination with high voltage or high-capacity electrodes with novel liquid electrolyte recipes or solid-state electrolytes. Moreover, we have mutual interest in the development of, e.g., Na-ion and Mg-ion batteries. Hence, our research focus on the synthesis of advanced materials and the engineering of the interfaces between the individual components and their characterization by using a wide spectrum of techniques at lab and large-scale facilities combined with computational methods.

Faculty members who are involved in FACETs work on battery material are:

Prof Daniel Rettenwander, Assoc. Prof Nils Wagner, Prof Sverre Magnus Selbach, and Prof Ann Mari Svensson

The battery research in FACET is strongly coordinated with battery work in the electrochemistry group, lead by Prof. Ann Mari Svensson.

Research Interests

*Under construction - new content is coming soon*

Experimental Equipment

*Under construction - new content is comming soon*

F.H. Fagerli, P. E. Vullum, T. Grande, Z. Wang, S. M. Selbach, K. Wiik, N. P. Wagner

Bulk Substitution of F-terminations from Ti3C2Tx MXene by cation pillaring and gas hydrolysation

FlatChem (2023)

F. H. Fagerli, Z. Wang, T. Grande, H. Kaland, S. M. Selbach, N. P. Wagner and K. Wiik

Removing Fluoride-Terminations from Multilayered V2CTx MXene by Gas Hydrolyzation

ASC Omega (2022)

E R. Østli, Y. Tesfamhret, S. Wenner, M. J. Lacey, D. Brandell, A. M. Svensson, S. M. Selbach and N. P. Wagner

Limitations of Ultrathin Al2O3 Coatings on LNMO Cathodes

ACS Omega 6 (2021) 45

J. Hadler-Jacobsen, F. H. Fagerli, H. Kaland and S. K. Schnell

Stacking Sequence, Interlayer Bonding, Termination Group Stability and Li/Na/Mg Diffusion in MXenes

ACS Materials Lett. 3 (2021) 1369–1376

I. T. Røe and S. K. Schnell

Slow surface diffusion on Cu substrates in Li metal batteries

J. Mater. Chem. A (2021)

H. Kaland, F. H. Fagerli, J. Hadler‐Jacobsen, Z. Zhao‐Karge, M. Fichtner, K. Wiik and N. P. Wagner

Performance Study of MXene/Carbon Nanotube Composites for Current Collector‐ and Binder‐Free Mg–S Batteries

ChemSuSChem (2021)

H. Kaland, J. Hadler-Jacobsen, F. H. Fagerli, N. P. Wagner, S. K. Schnell and K. Wiik

Dipentamethylene Thiuram Tetrasulfide-Based Cathodes for Rechargeable Magnesium Batteries

ACS Appl. Energy Mater. 3 (2020) 10600-10610

L. Wang, B. Jiang, P. E. Vullum, A. M. Svensson, A. Erbe, S. M. Selbach, H. Xu, and F. Vullum-Bruer

High Interfacial Charge Storage Capability of Carbonaceous Cathodes for Mg Batteries

ACS Nano 12 (2018) 2998–3009.

L. Wang, Z. Wang, P. E. Vullum, S. M. Selbach, A. M. Svensson and F. Vullum-Bruer

Solvent-Controlled Charge Storage Mechanisms of Spinel Oxide Electrodes in Mg Organohaloaluminate Electrolytes

Nano Lett. 18 (2018) 763-772.

K. Inzani, M. Nematollahi, F. Vullum-Bruer, T. Grande, T. W. Reenaas and S. M. Selbach

Electronic Properties of Reduced Molybdenum Oxides

Phys. Chem. Chem. Phys. 19 (2017) 9232-9245.

K. Inzani, M. Nematollahi, S. M. Selbach, T. Grande and F. Vullum-Bruer

Progression of reduction of MoO3 observed in powders and solution processed thin films

Thin Solid Films 626 (2017) 94-103.

L. Wang, K. Asheim, P. E. Vullum, A. M. Svensson and F. Vullum-Bruer

Sponge-like Porous Manganese(II,III) Oxide as a Highly Effi-cient Cathode Material for Rechargeable Magnesium Ion Batteries

Chem. Mater. 28 (2016) 6459-6470.

N. P Wagner, P. E. Vullum, M. K. Nord, A. M. Svensson and F. Vullum-Bruer

On Vanadium Substitution in Li2MnSiO4/C as Positive Electrode for Li-ion Batteries

J. Phys. Chem. C 120 (2016) 11359-11371.

X. Chen, F. L. Bleken, O. M. Løvvik and F. Vullum-Bruer

Comparing electrochemical performance of transition metal silicate cathodes and chevrel phase Mo6S8 in the analogous rechargeable Mg-ion battery system

J. Power Sources 321 (2016) 76-86.

C. E. L. Foss, A. M. Svensson, S. Sunde and F. Vullum-Bruer

Edge/basal/defect ratios in graphite and their influence on the thermal stability of lithium ion batteries

J. Power Sources 317 (2016) 177-183.

N. Wagner, A. M. Svensson and F. Vullum-Bruer

Liquid-feed flame spray pyrolysis as alternative synthesis for electrochemically active nano-sized LiMn2SiO4

Transl. Mater. Res. 3 (2016) 025001.

K. Inzani, T. Grande, F. Vullum-Bruer and S. M. Selbach

A van der Waals Density Functional Study of MoO3 and Its Oxygen Vacancies

J. Phys. Chem. C 120 (2016) 8959-8968.

N. Wagner, A. M. Svensson and F. Vullum-Bruer

Flame-Made Lithium Transition Metal Orthosilicates

Electrochimica Acta 203 (2016) 246-256.

N. P. Wagner, A. R. M. Dalod, A. M. Svensson and F. Vullum-Bruer

Fe and V Substituted Li2MnSiO4/C As Potential Cathode Material for Li-Ion Batteries

ECS Trans. 64 (2015) 33-45.

N. Wagner, A. M. Svensson, F. Vullum-Bruer

Effect of carbon content and annealing atmosphere on phase purity and morphology of Li2MnSiO4 synthesized by a PVA assisted sol–gel method

Solid State Ionics 276 (2015) 26-32.

O. S. Burheim, M. A. Onsrud, J. G. Pharoah, F. Vullum-Bruer, P. J. S. Vie

Thermal Conductivity, Heat Sources and Temperature Profiles of Li-Ion Batteries

ECS Trans. 58 (2014) 145-171.

F. Lou, H. Zhou, T. D. Tran, M. E. Melandsø Buan, F. Vullum-Bruer, M. Rønning, J. C. Walmsley and D. Chen

Coaxial Carbon/Metal Oxide/Aligned Carbon Nanotube Arrays as High-Performance Anodes for Lithium Ion Batteries

ChemSusChem. 7 (2014) 1335–1346.

H. Zhou, F. Lou, P. E. Vullum, M.-A. Einarsrud, De Chen and F. Vullum-Bruer

3D aligned-carbon-nanotubes@Li2FeSiO4 arrays as high rate capability cathodes for Li-ion batteries

Nanotechnology 24 (2013) 435703.

HQ. Lu, H. Zhou, A. M. Svensson, A. Fossdal, E. Sheridan, SQ. Lu, F. Vullum-Bruer

High capacity Li[Ni0.8Co0.1Mn0.1]O2 synthesized by sol–gel and co-precipitation methods as cathode materials for lithium-ion batteries

Solid State Ionics 249-250 (2013) 105-11.

F. Lou, H. Zhou, F. Vullum-Bruer, T. D. Tran and De Chen

Synthesis of carbon nanofibers@MnO2 3D structures over copper foil as binder free anodes for lithium ion batteries

J. Energy Chem. 22 (2013) 78–86.

H. Zhou, M.-A. Einarsrud and F. Vullum-Bruer

In situ XRD and EIS of a nanoporous Li2FeSiO4/C cathode during the initial charge/discharge cycle of a Li-ion battery

J. Power Sources 238 (2013) 478–484.

F. Lou, H. Zhou, F. Huang, F. Vullum-Bruer, T. D. Tran and De Chen

Facile synthesis of manganese oxide/aligned carbon nanotubes over aluminium foil as 3D binder free cathodes for lithium ion batteries

J. Mater. Chem. A 1 (2013) 3757-3767.

H. Zhou, M.-A. Einarsrud and F. Vullum-Bruer

High capacity nanostructured Li2FexSiO4/C with Fe hyperstoichiometry for Li-ion batteries

J. Power Sources 235 (2013) 234.

C. E. L. Foss, A. M. Svensson, S. Sunde and F. Vullum-Bruer

Electrochemical Impedance Spectroscopy of a Porous Graphite Electrode Used for Li-Ion Batteries with EC/PC Based Electrolytes

ECS Trans. 41 (2012) 1-6.

H. Zhou, M.-A. Einarsrud and F. Vullum-Bruer

PVA-assisted combustion synthesis and characterization of porous nanocomposite Li2FeSiO4/C

Solid State Ionics 225 (2012) 585-589.

Scientific Highlights

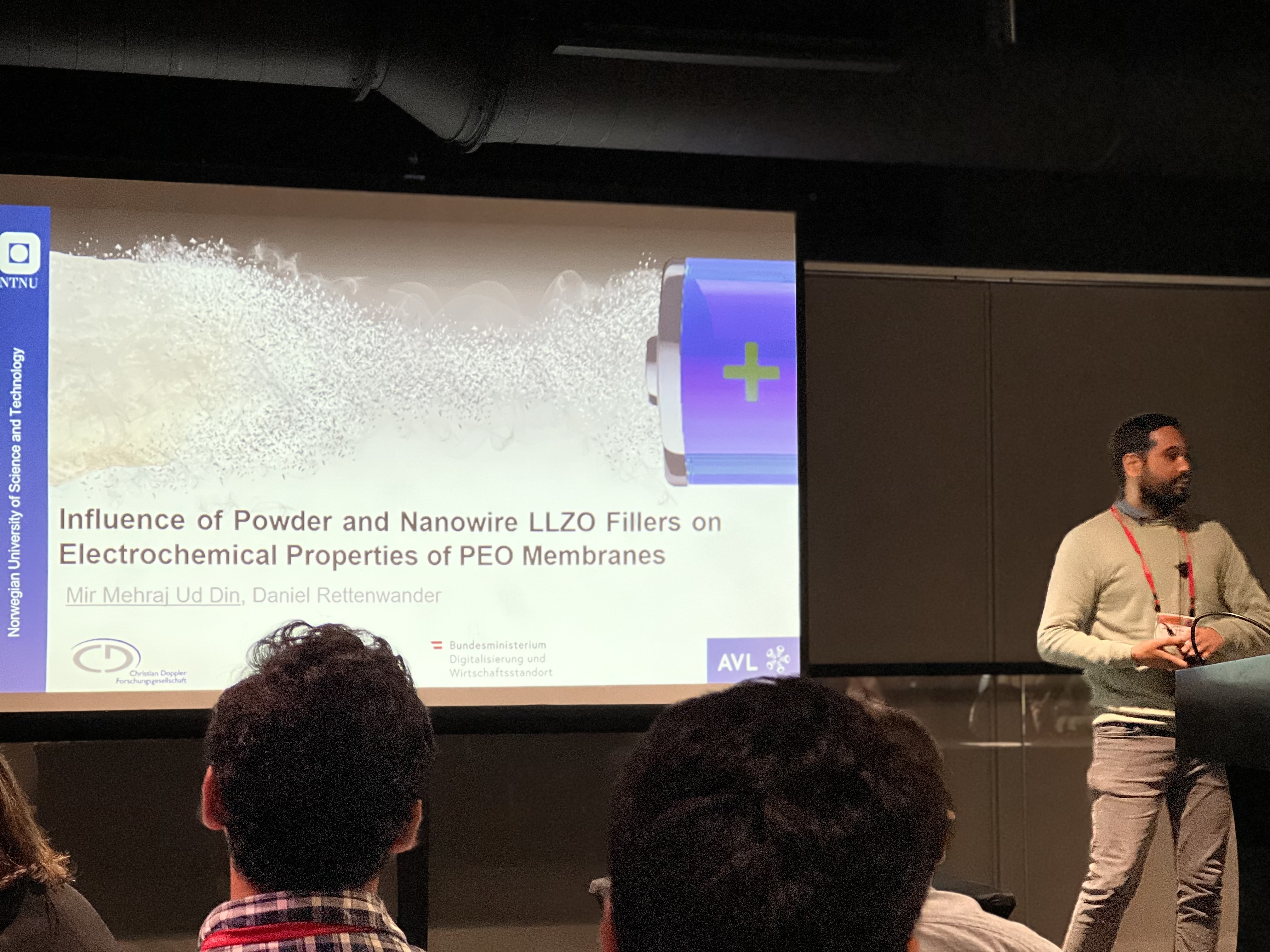

Austria's Magazine for Economy, Technology and Research (Chemiereport.at) has published an article (in German) about The International Christian Doppler (CD) Laboratory for Solid State Batteries led by Associate Professor Daniel Rettenwander .

Daniel Rettenwander and Mir Mehraj Ud Din joned the Kick-Off Meeting of Daniels new M-ERA.NET Project SOLIMEC at the UAM in Madrid

Associate Professor Daniel Rettenwander received funding from the RCN. He will coordinate a consortium based on UiO, Freyr, and Cerpotech developing advanced composite electrolytes. A PhD position will be announced soon.

Our PhD-student Florian and Postdoc Mir did great contributions at the Solid-state ionics (SSI-23) in Boston (23rd International Conference on Solid State Ionics (SSI 23) (mrs.org))

We congratulate Maria and Daniel on getting the 2x M-Era-Net project funded! This is also associated with 2 new post-doc positions

Selected publications

L. Wang et. al., Solvent-Controlled Charge Storage Mechanisms of Spinel Oxide Electrodes in Mg Organohaloaluminate Electrolytes, Nano Lett. 18 (2018) 763-772.

L. Wang et. al., Sponge-like Porous Manganese(II,III) Oxide as a Highly Efficient Cathode Material for Rechargeable Magnesium Ion Batteries, Chem. Mater. 28 (2016) 6459-6470.

N. P Wagner et.al., On Vanadium Substitution in Li2MnSiO4/C as Positive Electrode for Li-ion Batteries, J. Phys. Chem. C 120 (2016) 11359-11371.