Laser Physics Group - Department of Physics

Laser Physics Group

Generation of ultimately short pulses in the mid-infrared wavelength range is a challenging aim, but very desirable as this novel class of fiber-based lasers opens up a wide field of research and industrial applications. Indeed, the visible wavelength range corresponds to energy transitions of atoms, whereas mid-infrared range above 2 micrometers is where most of the molecules have their "fingerprints".

As such, this class of lasers is particularly suitable for "real-world" applications. Such lasers have enormous potential for many applications of scientific, bio-medical and industrial importance. They can can be used for such applications as ultrasensitive gas analysis using, for example, double frequency combs, or for bio-imaging and time-resolved measurements as well as for THz generation, just to name a few.

Fiber laser vs. crystal laser

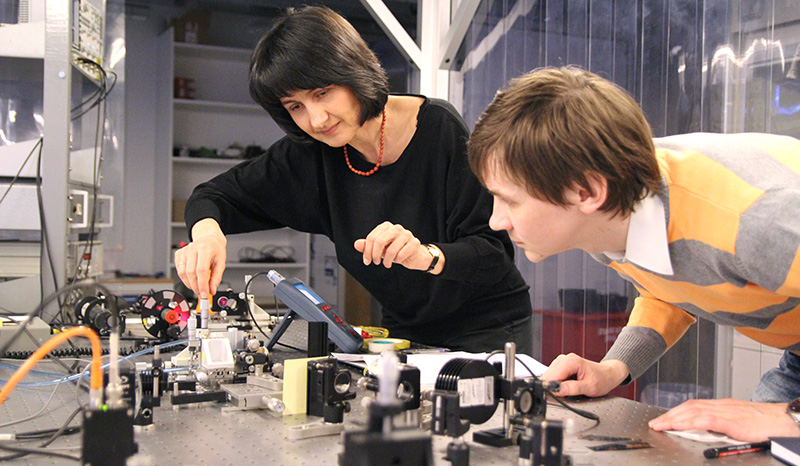

We have advanced instruments in the NTNU Laser Lab. Research here is done both on solid state laser based on crystals and fiber laser.

The advantage with fiber laser is that it is more sensitive and therefore gives more reliable results than crystal based laser. It can also be made more compact and more durable and used for more practical applications. Crystal based laser is a strong challenger in its flexible construction and a generally wider spectrum of operation. NTNU has sophisticated equipment and experience that is used to create lasers with different properties, pulses, wavelength and colours etc.

The laser physics laboratory

It is important that all the components are exactly placed at the right location. The lab tables has a honey comb structure that reduces vibrations and makes it stable. Optomechanical translators are used to help the optical components to align and position the laser beam correctly.

Oscilloscope instruments are used to visualize the duration of the laser pulse. In clean air, you cannot see the trace of the laser beam, even though it is considered a visible beam. Diagnostical instrument used to measure the pulse length in time units.

Mirrors and beam spiltters are used. The mirrors direct the laser beam to the desired location while the splitters divide the beam into two parts allowing many different types of experiments.

Electric current creates the laser light inside laser diodes. The light will be coupled (connected) into the fiber to transport it to a desired location. Optical fiber in protective coating transports the laser beam. The lab has instruments for precise cutting and splicing of fibers. Fiber that contains infrared light shines with a blue colour in the dark. This process is called fluorescence. Fluorescence is usually undesired in laser as it wastes energy and unnecessarily emits light.

The group's research interests are in the laser and nonlinear optics field, with an emphasis on ultrafast nonlinear optical phenomena and their applications. The group is focusing on the generation of intense, ultrashort optical pulses in the mid-infrared spectral region with time durations close to the shortest possible, consisting of only two or three optical cycles. Such pulses have extremely broad spectral bandwidth in the wavelength range where most of the molecule have their "fingerprints".

Research projects

UNLOCK - Universal Non-Linear Optical Crystal based intense laser light systems

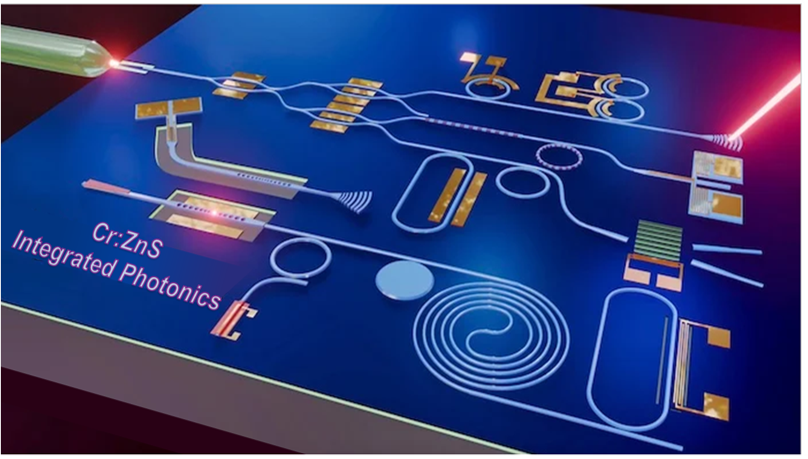

The project is a large international collaboration effort aimed at the development of advanced active ion doped and passive nonlinear optical materials based on II-VI single crystalline layers for use in particularly compact integrated and robust mid-infrared laser systems operating in the mid-infrared wavelength region between 2 and 18 microns.

Read more about the UNLOCK research project

MIR - Mid-IR ultra-short pulsed laser technology for science and green industry

MIR project is an interdisciplinary effort that aims at the development of mid-infrared ultra-fast laser technology as an enabling technology for industry, green energy and environmental sensing as well as fundamental science.

Read more about the MIR research project

Media coverage

Norsk forskermiljø utvikler verdens mest avanserte laser (Aftenposten vitenskap) (PDF) (In Norwegian)

Project summary

Development in this project of the new, ultra-Precise laser technology enables fabrication of silicon solar cells that will be produced without material waste.

In the manufacturing process of silicon-based solar cells the precisely cut blocks of silicon wafers will be produced, which are then further processed and fabricated to the solar cells we know.

However, during the cutting process a lot of excess material is being produced. In order to streamline production and reduce costs, it is important for industry to reduce this waste of expensive materials and make the technology 'kerfless'.

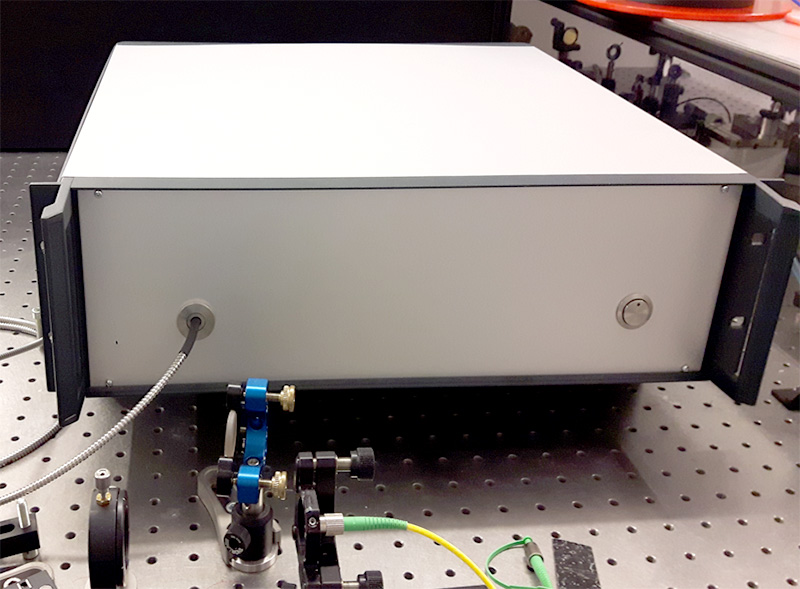

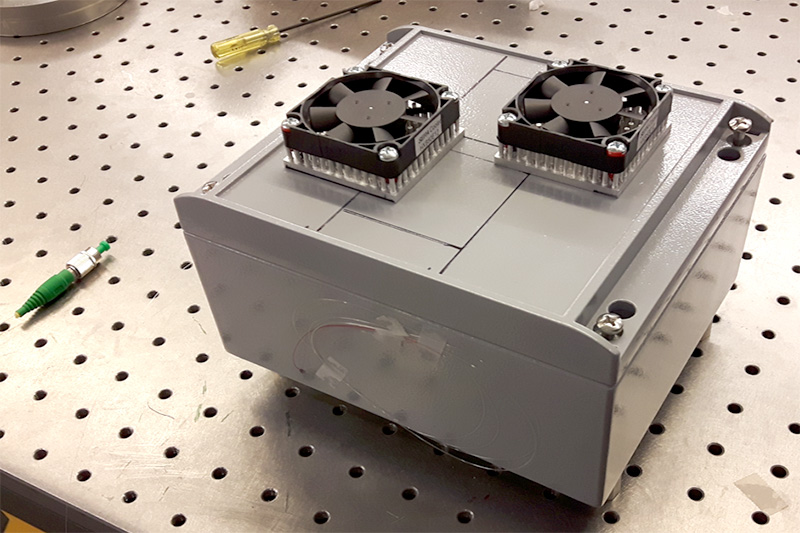

Now scientists at NTNU and SINTEF together with other partners, including an NTNU startup company Atla lasers, are developing new laser technology to create thin films of silicon for solar cells, without creating excess material. The laser can be used to cut slices of material, and to create ultrathin slices under the material surface.

Industry partner Atla Lasers have emerged from NTNU. The team is partnering also with the other German and Norwegian lasers and photovoltaics industry. The new laser technology can also be applied to other semiconductor materials in electronics and telecommunications industry.

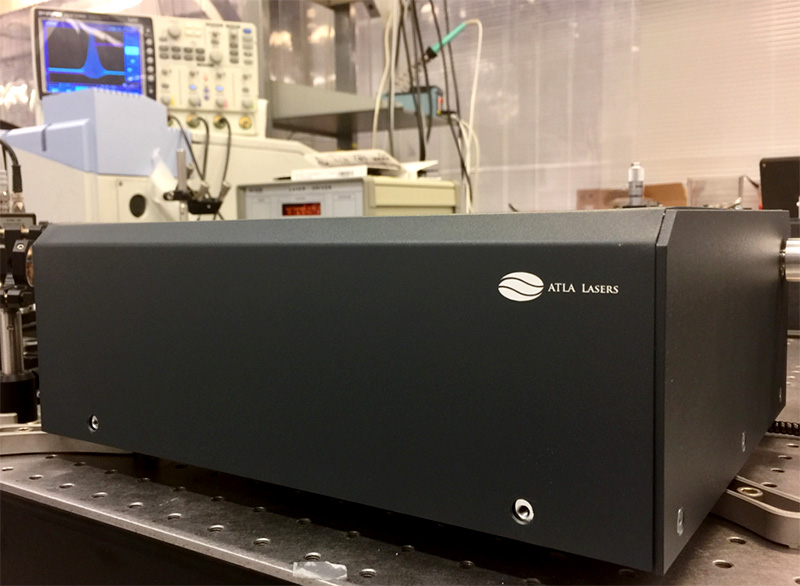

ATLA Lasers

ATLA Lasers is a high-tech company that develops, industrializes and commercializes in international markets industrial grade cost effective sub-picosecond and femtosecond fiber-based laser products that operate in the mid-infrared region of the electromagnetic spectrum, in the range 2µm to 4µm.

Our target application areas are real-time spectroscopy for fast sensitive hydrocarbon (oil and gas) sensing and molecular fingerprinting, as well as high throughput fine materials processing. For these applications, our proprietary laser technology offers important competitive advantages and unique features.

ATLA was founded by a team of experienced managers, engineers and scientists with proven international business and scientific track records.

ATLA actively seeks to establish business partnerships and strategic cooperation frameworks with other companies and entities.

Products

Demonstrated at Photonics Exhibit, Sweden, Nov. 2016

Product description (PDF)

Product description (PDF)

Latest product, demonstrated at Photonics Europe 2018 in Strasbourg

Contact

Irina T. Sorokina

irina.sorokina@atla-lasers.com

Irina T. Sorokina (PDF)

Nikolai Tolstik (PDF)

We have advanced instruments in the NTNU Laser Lab. Research here is done both on solid state laser based on crystals and fiber laser.

There are three parameters in laser technology that influence results:

- The wavelength

- The power applied

- The pulse duration

There are two different types of lasers: constant or pulsed. Shorter pulses give a wider spectrum (wavelength) and therefore more areas of use. Nanosecond pulses (10-9 of a second) can be used for marking, for instance patterns on your smart phone. When using femtosecond pulses (10-15 of a second) most material change form from solid to gas. In their research, Irina and Nikolai work on creating the shortest pulse possible.

Principal investigators

-

Christoph Brüne Associate Professor

+47-73413246 christoph.brune@ntnu.no Department of Physics -

Christos Grivas Head Engineer

christos.grivas@ntnu.no Department of Physics -

Vladimir Kalashnikov Researcher

+4796880162 vladimir.kalashnikov@ntnu.no Department of Physics -

Alexander Rudenkov Researcher

+47-73412536 alexander.rudenkov@ntnu.no Department of Physics -

Irina T Sorokina Professor

+47-73593633 +4791897909 irina.sorokina@ntnu.no Department of Physics

Collaborators

-

Paul Gunnar Dommersnes Professor

+47-73413079 +4794186110 paul.dommersnes@ntnu.no Department of Physics -

Andreas Erbe Professor of Corrosion and Interface Chemistry

+47-73594048 andreas.erbe@ntnu.no Department of Materials Science and Engineering -

JOF Departed

jon.fossum@ntnu.no Department of Physics -

Ursula Gibson

+47-73593336 ursula.gibson@ntnu.no -

Matti Knaapila Researcher

+4790982196 matti.knaapila@ntnu.no Department of Physics -

Olof Mikael Lindgren Professor

+47-73593414 mikael.lindgren@ntnu.no Department of Physics -

Barbara Pacáková Researcher

+47-73413135 +4748509263 barbara.pacakova@ntnu.no Department of Physics -

Marisa Di Sabatino Professor

+47-73551205 +4798243462 marisa.di.sabatino@ntnu.no Department of Materials Science and Engineering

Former group members

Nikolai Tolstik

Roland Richter

Ingrid Bakke

Cherrie S. Lee

Sebastien Rigaud

Paul DelaValé

Marius Skogen

Upcoming event!

International workshop on Innovation for Quantum Sensing Technologies

Dates: 06.06.2025 – 09.06.2025

Venue: Thon hotel Svolvaer, Lofoten Islands, Norway

Download the pogramme (pdf)