Archive news 2020 - SFI Metal Production

News from 2020

Continuation strategy for the SFI

The SFI centre funding period is coming to an end in the beginning of 2023. It is important to start the in-depth discussions on how to ensure that the good results and strong research groups are maintained and prolonged. Our ambition is to develop a new SFI project based on the strong fundament of SFI Metal Production. March 2nd we organized a strategy seminar for the SFI Management team on this topic.

New EU-financed project for SINTEF and NTNU

SINTEF and NTNU are partners in a newly awarded EU financed project called HARARE. The project will demonstrate sustainable pathways to produce metals using hydrogen as an enabler. Hydrogen as a reductant to substitute carbon is one of the few ways metallurgical industry can potentially become truly free of CO2-emissions.

New spin-off project on automotive battery recycling

In 2019, it was estimated that only about 5 % of lithium-ion batteries were recycled. The market for lithium-ion batteries is expected to grow tenfold the coming decade, mostly driven by the growth in the number of electrical vehicles. The low recycling rate and the high growth demonstrates the need for increased focus on recycling and improved recycling technologies. A team of scientists from SINTEF will the coming year be working on innovative solutions for recycling of batteries. Their new ideas spring from their wide experience in recycling of metals and molten salt electrochemistry. SINTEF is financing the project so that new inventions can be patented by SINTEF. Anne Kvithyll, Research Domain leader in SFI Metal Production, is the contact person to this project.

When you can't go to Japan - go to Finnsnes!

Every 5-10 years NTNU professors are excused of their teaching duties and have the possibility to visit other universities, or cooperating partners, to gain insight. 2020 was the year that Professor Merete Tangstad planned to go to China and Japan to spend some time at University of Science and Technology Beijing and University of Tokyo. Read about Merete’s experience with sabatical 2020, in her own words:

A Roundtable Discussion: Challenges for a Sustainable Aluminum Industry and Advice for the Next Generation

Do you wonder what five well-known specialists both from primary and secondary aluminium industry think is the most critical challenges how we might face them? Then you should read the report from the discussion initiated by SFI RD leader Anne Kvithyld that is printed in the October issue of The Journal of The Minerals, Metals & Materials Society, JOM. You will notice the more optimistic view from China than USA and Europe. And last but not least you will find out what people late in their carriers would have liked to know when they started.

Visiting researcher at SFI Metal Production

This Autumn researcher Kurian Vachaparambil has joined SFI Metal Production to work in close collaboration with Kristian Etienne Einarsrud (IMA, NTNU) and Halvor Dalaker (SINTEF Industry). The aim of the project is to develop a simulation framework which can be used to simulate industrially relevant reactive flow simulations which can treat both fluid dynamics, heat transfer and chemical reactions.

This Autumn researcher Kurian Vachaparambil has joined SFI Metal Production to work in close collaboration with Kristian Etienne Einarsrud (IMA, NTNU) and Halvor Dalaker (SINTEF Industry). The aim of the project is to develop a simulation framework which can be used to simulate industrially relevant reactive flow simulations which can treat both fluid dynamics, heat transfer and chemical reactions.

Simulating of chemically reactive flows are difficult due to the complex coupling between fluid flow, heat transfer and chemical reactions. Modelling these phenomena can provide knowledge to understand the operation of experimental and industrial reactors as well as in developing strategies to optimize these processes like by reducing NOx generation.

Kurian recently submitted his PhD thesis at the electrochemistry group at IMA, NTNU. In his PhD he focused on developing multiphysics solver for electrochemical gas evolution on OpenFOAM.

Field trip to Alcoa Mosjøen

As part of the kick-off for our new students working on aluminium, a field trip to Alcoa Mosjøen was arranged. As some of the older students for various reasons had not visited a smelter before, the delegation was extended to 2 MSc students, 3 PhD students and 2 Associate Professors.

Congratulations Dr Jayakumari!

Congratulations to Dr Sethulakshmy Jayakumari who successfully defended her thesis September 10th. Sethulakshmy did an excellent presentation of the trial lecture: “Production of Mn by electrolyses – state of the art and future prospects” followed by the presentation of her PhD thesis “Formation and characterization of β-and α-Silicon Carbide produced during Silicon/Ferrosilicon process”.

More sustainable production of Silicon from quartz

The project SisAl Slag Valorisation coordinated by prof. Gabriella Tranell receives funding from the EU body EIT Raw Materials. Prof. Ann Mari Svensson and Assoc. Prof. Jafar Safarian will also be active in the project. The project is an acceleration action within the thematic area: Increased resources efficiency in mineral and metallurgical process. The duration of the project is three years and the total budget is about 4.8 M Euro.

Postdoctor Vincent Canaguier in new position at SINTEF Industry

In August Postdoctor at SFI Metal Production Vincent Canaguier started in a new position as researcher at SINTEF Industry. Vincent har joined the Process metallurgy and raw materials group. At SINTEF he will be working with many projects, including SFI projects. In the beginning he will focus particularly on manganese projects.

As a postdoctor at SFI Metal Production Vincent has worked mainly with kinetics of the reduction reactions in the SiMn production process. He has been postdoctor for two years, but he has been working for NTNU for 6 years overall, including the Ph.D.

Vincent expect that working at SINTEF presents new challenges: "It is important to keep track on the hours worked and have a good control on the different projects I work on simultaneously. Also, while I was working on my own projects as a PhD candidate and as postdoctor, I now share the project workload with my colleagues to a higher extent. Thus, we provide a collective answer to scientific questions."

Congratulations and best of luck in your new job Vincent!

Congratulations Dr Jusnes!

Congratulations to Dr Karin Fjeldstad Jusnes who successfully defended her thesis June 19th. Karin did an excellent and comprehensive presentation of the trial lecture: “Sustainable Low-Carbon Footprint Production of Si and FeSi” followed by the presentation of her PhD thesis “Phase transformations and thermal degradation in industrial quartz”.

100 persons registered for the online Silicon Conference June 16th

![]() The Silicon for Chemical and Solar Industry conference was originally going to be arranged in Trondheim from15th to 18th of June 2020. Due to the Covid-19 situation the confernce was changed to an integrated webinar with proceedings and online talks: A 3 hours plenary webinar, taped presentation of the rest of the papers, as well as the standard proceedings.

The Silicon for Chemical and Solar Industry conference was originally going to be arranged in Trondheim from15th to 18th of June 2020. Due to the Covid-19 situation the confernce was changed to an integrated webinar with proceedings and online talks: A 3 hours plenary webinar, taped presentation of the rest of the papers, as well as the standard proceedings.

The aim of Silicon for the Chemical and Solar Industry conference is to discuss new development in Silicon Process Technology, Silicon Quality Assessment and Performance in the Subsequent Chemical Reactions including resource, energy and environmental issues.

The different processes from quartz to metallurgical and solar grade silicon, silicones or electronic silicon are strongly linked, and a sustainable process is dependent on a thorough understanding of the total process. The development of production of solar grade silicon directly by metallurgical routes is also included.

Worldwide almost 100 participants from silicon industry, users and academia registered for the conference.

Congratulations Dr Azof!

Congratulation to Dr Fabian Imanasa Azof who successfully defended his thesis May 8th. Fabian did an excellent presentation of the trial lecture “Alumina quality, performance and applications: Dependence on ore quality and production process” followed by the presentation of his PhD thesis “Pyrometallurgical and Hydrometallurgical Treatment of Calcium Aluminate-containing Slags for Alumina Recovery”.

Spring meeting April 29th – A successful online webinar

April 29th SFI Metal Production organized the yearly Spring Meeting. Due to the extraordinary coronavirus situation we were not able to have a physical meeting this time. The traditional two-day spring meeting were replaced by an all-day online webinar. A positive effect was that the online solution enabled more participants from the industry and research institutions outside Trondheim to join the meeting.

to the webinar.

Ketil Rye, Process Technology Manager at Alcoa, congratulated the centre on a very well-organized agenda and a professional performance in the SFI Spring Webinar: “Alcoa had more than 15 direct participant and even more clustered around their computers to watch the latest news from the activities in Trondheim. Making the spring meeting as a webinar enabled a very good dissemination of results in spite of the present travel restrictions. Actually, in many respects the webinar format enabled a much better result dissemination than the traditional face-to-face meetings, as we could now invite participants throughout our world-wide company.” Another upside was the low cost of participation, as no time was spent in travel and the net time consumed was focused on the hours the webinar was open.

TWO NEW INTPART PROJECTS TO SFI METAL PRODUCTION!

Professors Merete Tangstad and Gabriella Tranell from SFI Metal Production have received funding for INTPART projects from the Research Council of Norway.

INTPART is a programme for International Partnerships for Excellent Education, Research and Innovation. The objective of the INTPART programme is to develop world-class research and education in Norway through long-term international cooperation with priority partner countries: Brazil, Canada, China, India, Japan, Russia, South Africa, the US, Germany and France. The purpose is lay a foundation that enables such research groups to develop longterm relations with strong academic groups in the priority countries.

How does materials relate to society?

Member of the SFI Scientific Committee, Professor Jean-Pierre Birat, has published a book with a holistic vision of the connection between materials science, the environment and society. The title of the book is Sustainable Materials Science - Environmental Metallurgy.

In his book Birat stresses that it is no longer possible to think of materials from the restricted standpoint of Materials and Engineering Sciences.

In his book Birat stresses that it is no longer possible to think of materials from the restricted standpoint of Materials and Engineering Sciences.

The book examines how materials relate to society with complex metrics, but also how they generate eco-social services, and have agency along with the people who use them and invent them (Actor Network Theory). Materials are at the core of our societies and of our economies. They are part of pressing environmental challenges, but they also provide powerful answers.

There are many excellent treatises on materials science and more on industrial ecology. However, the con-nection with the social dimension of sustainability is still rarely discussed and the pluridisciplinary cocktail of approaches used here is truly new.

In its pluridisciplinary approach the book is meant for students, researchers, engineers, and concerned citizens interested in how materials, nature and people interact.

Jean-Pierre Birat is a metallurgist, who discovered environmental issues as a researcher with a major steel producer. He is a graduate of the Paris School of Mines and UC Berkeley. He has worked in France (IRSID, ArcelorMittal Research), Japan and Belgium (ESTEP), headed the ULCOS program and has been organizing the “Materials and Society” conferences for 14 years. He teaches the content of this book at the University of Science and Technology of Beijing.

Field trip to Alcoa Mosjøen for new students on alumina dissolution

As part of the kickoff for our new students on alumina dissolution, a field trip to Alcoa Mosjøen was organized in february.

Guided by Kim Ronny Elstad and Martin Grimstad, we were given a detailed tour in potrooms to see alumina feeding in action.

Guided by Kim Ronny Elstad and Martin Grimstad, we were given a detailed tour in potrooms to see alumina feeding in action.

In order to gain insight of the real process, the crust was broken, enabling visualization and video recording of raft formation – as performed by summer interns earlier.

Results from the last year were showcased by PhD student Sindre Gylver. Our BSc students Simen Aase, Simen Bekkevoll and Sigmund Forberg and MSc student Maria Frenkel participated in good discussions with representatives from Alcoa Mosjøen.

Activities will be followed up during the coming months by our students, further probing the behaviour of alumina in primary aluminium production.

Norwegian Process Industry and “Green Deal”

Norwegian industry is tightly connected to Europe through power trading. How is the power market system connected to the vision of a clean industry? How will «Green Deal» affect Norwegian industry? Are we able to reach the goals defined in the government’s roadmap for the process industry by 2050? These questions were addressed at an all-day seminar in Oslo February 4th.

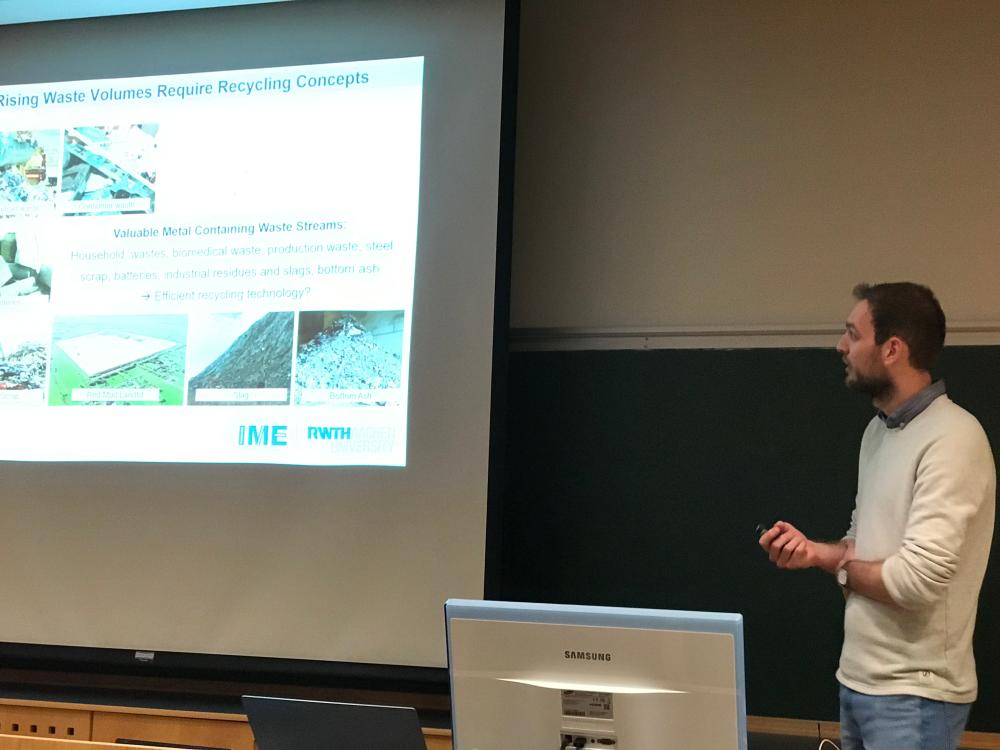

Well attended joint seminar for the SFI and RWTH Aachen

Organizers from NTNU with guests from Aachen. First row: Sven Anton Halvorsen, Mertol Gökelma, Hugo Lucas, Gabriella Tranell, Shokouh Haghdani, Hossein Salehi Second row: Gunnar Hovestadt, Marcus Sommerfeld, Bernd Friedrich, Manuel Sparta, Stefan Andersson, Mengyi Zhu, Adamantia Lazou.

13-14 January SFI Metal Production and IME, RWTH Aachen, organized a joint seminar entitled “The Versatile SAF”.

The program included presentations from both academic and industrial partners in the SFI focusing primarily on production and modelling of primary production of metals using SAF Technology. Presentations from Aachen focused on various applications of SAF technology in processing of exotic materials such as sea nodules and valorization of secondary materials such as incineration bottom ash and slags from metal production.

The program included presentations from both academic and industrial partners in the SFI focusing primarily on production and modelling of primary production of metals using SAF Technology. Presentations from Aachen focused on various applications of SAF technology in processing of exotic materials such as sea nodules and valorization of secondary materials such as incineration bottom ash and slags from metal production.

The seminar was well attended with over 30 participants. RWTH Aachen is a strategic partner for collaboration in both EU projects and student exchange.

Happy New Year 2020

Happy New Year from Metal Production