Mechatronics Laboratory - Valgrinda

Manufacturing

The Manufacturing research group focuses on sustainable manufacturing processes in three main areas: Metal forming; AM, subtractive and manufacturing metrology; Joining, welding and assembly. This group is closely linked to the NTNU Aluminium Product Innovation Centre (NAPIC), MANULAB - national infrastructure and the Gemini Center for Metal Forming.

Metal forming

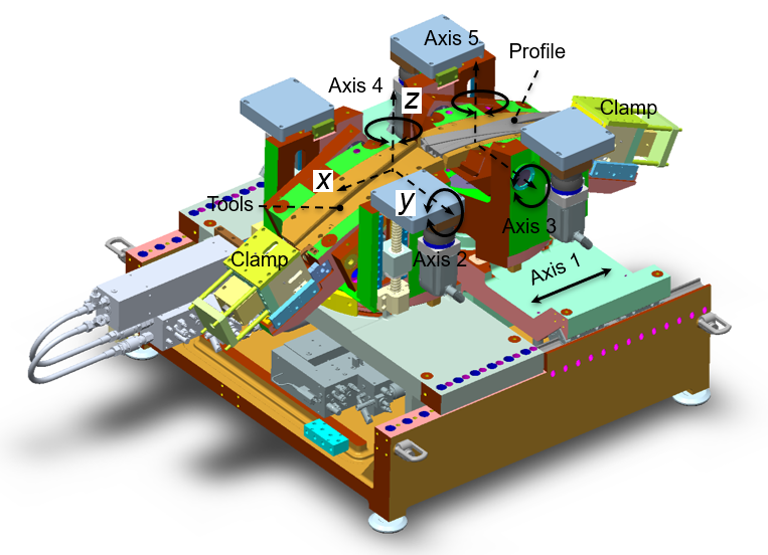

In recent years, the demand for lightweight materials, particularly aluminum, has surged as part of a broader push toward more sustainable solutions. This trend is especially evident in electric mobility. Norway has a long history of a key player in the aluminum value chain. The Manufacturing group's research and educational activities are centered around not only recycling and re-use of extruded aluminum products but also incorporate traditional bending methods such as rotary draw bending, roll bending, and compression Bending. Furthermore, the group is actively exploring innovative processes like 3D flexible rotary stretch forming.

|

|

AM, subtractive and manufacturing metrology