Nanomechanical Lab

4 PhD & post doc positions available

4 PhD & post doc positions available

At least 4 new PhD and post doc positions in Hydrogen Embrittlement and Seawater Adhesion will be available from August 2023. If you are interested, please contact.

NML season's greeting 2022

NML season's greeting 2022

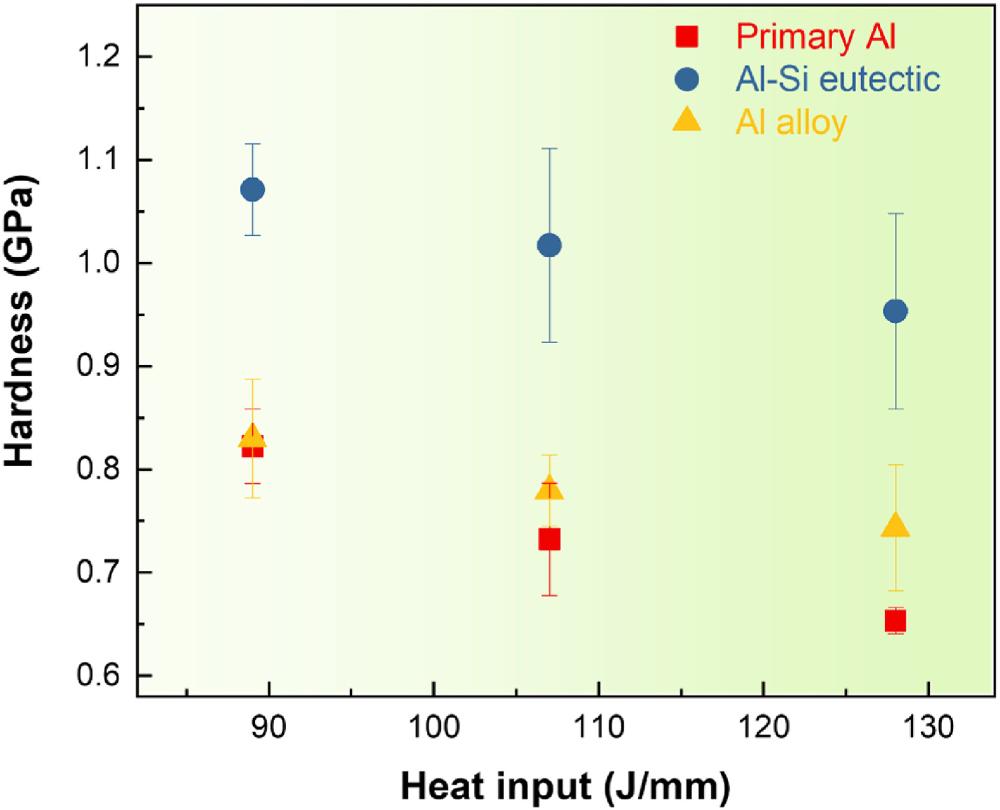

Effect of heat input on nanomechanical characteristics of additive manufactured alloys

Effect of heat input on nanomechanical characteristics of additive manufactured alloys

New paper published in Materials Science and Engineering: A, 2022, 860: 144288.

Wire-arc additive manufactured (WAAM-ed) Al 4047 alloys under different heat inputs were produced to investigate the effect of heat input on the nanomechanical properties by nanoindentation. The WAAM-ed Al alloys showed hypoeutectic microstructure that consisted of primary Al (α-Al) dendrite and ultrafine Al-Si eutectic. Interestingly, it is found that the hardness of α-Al dendrite and Al-Si eutectic decreased with the increasing heat input, in accordance with the trend of yield strength and microhardness in the previous studies. Different from the microscale mechanism explained by the grain growth model and Hall-Petch relationship, this work reveals the nanoscale mechanism regarding the effect of heat input on hardness, which is the enhanced solid solution strengthening produced by low heat input. However, the heat input had little effect on the SRS and activation volume. This work leads to new insights into the understanding of the heat input effect, and further benefits to improve the targeted mechanical properties and engineering applications of the AM-ed materials.

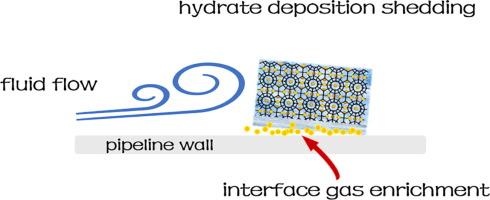

Novel interfacial gas-enrichment strategy is proposed for mitigating hydrate adhesion and blockage

Novel interfacial gas-enrichment strategy is proposed for mitigating hydrate adhesion and blockage

See our new publication in Chemical Engineering Journal, 2023, 453, 139918.

On achieving low hydrate adhesion force, a precise knowledge of the interactions between hydrate and solid surfaces is a prerequisite. By utilizing molecular dynamics simulations, gas hydrate with an intermediate layer (IML) containing varied gas content is brought to contact with several kinds of solid surfaces. The results show that the presence of gas layers or bubbles on the solid interface can fatally weaken hydrate adhesion strength, which indicates for the first time the possibility of surface chemical design and engineering in fabricating anti-hydrate surfaces. Based on this, a novel passive anti-hydrate surface design approach is proposed by means of an interface gas enrichment strategy to weaken hydrate adhesion strength on solid surfaces.

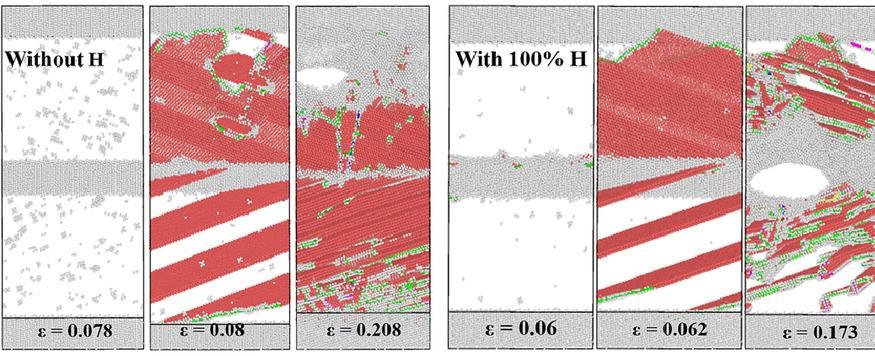

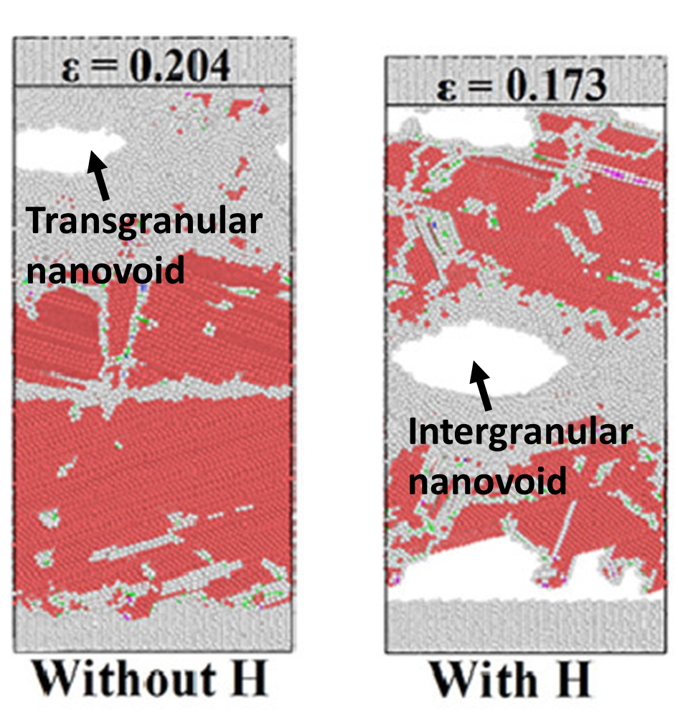

How hydrogen causes transgranular to intergranular fracture transition?

How hydrogen causes transgranular to intergranular fracture transition?

August 2022 Acta Materialia 239(156-163):118279

Without hydrogen, vacancy generation at grain boundary is limited and transgranular fracture mode dominates. When charged, hydrogen as a booster can enhance strain-induced vacancy generation by up to ten times. This leads to the superabundant vacancy stockpiling at the grain boundary, which agglomerates and nucleates intergranular nanovoids eventually causing intergranular fracture.

Find full article in ScienceDirect here.

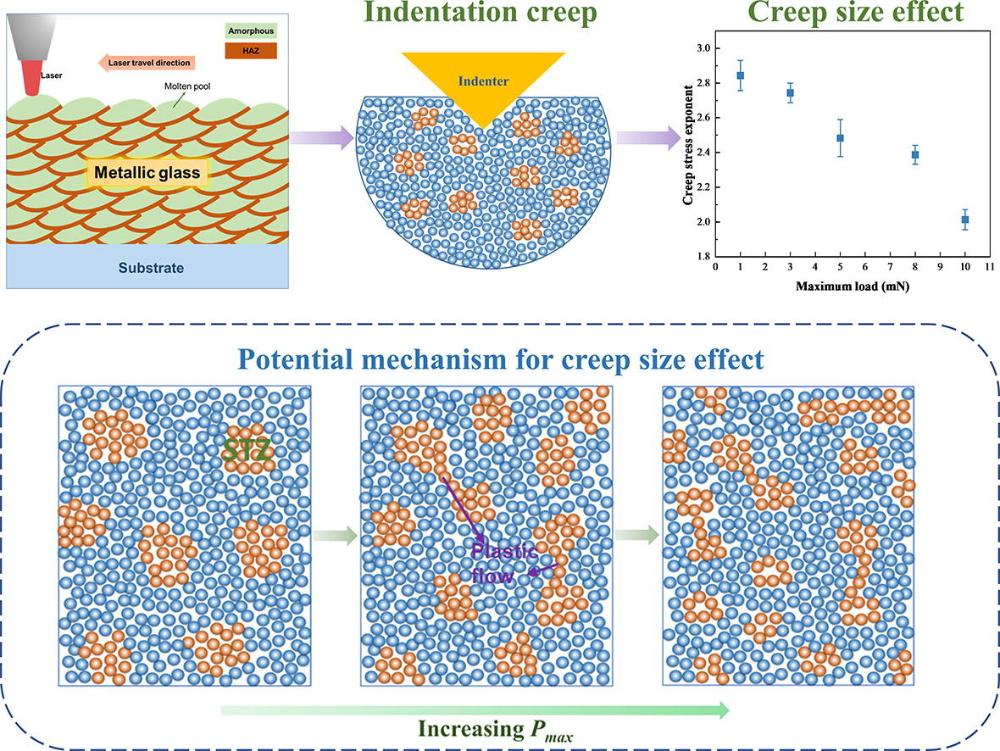

Creep of additive manufactured metallic glass

Creep of additive manufactured metallic glass

Size dependent creep behavior of AM-ed metallic glass published in Materials & Design, 2022, 218: 110723

The nanoscale creep behavior and creep size effect of a selective laser melted (SLM-ed) Zr-based metallic glass (MG) were investigated by aid of nanoindentation. The creep compliance and creep retardation spectra were extracted from the fitted parameters of the generalized Kelvin model. The creep stress exponent (n) and shear transformation zone (STZ) volume, as the indicators of creep mechanism, were estimated, demonstrating the creep mechanism is the non-Newtonian flow and the creep resistance decreased with the increscent peak loads. A potential mechanism for this creep size effect was revealed in this work: the smaller of the STZ volume, as well as the greater ratio of plastic flow under the higher maximum load, are responsible for the decreasing tendency of creep resistance. The significance of this work lies in the fact that it filled the blank of an in-depth understanding of the atomistic mechanisms in the AM-ed MG during the nanoscale creep deformation process.

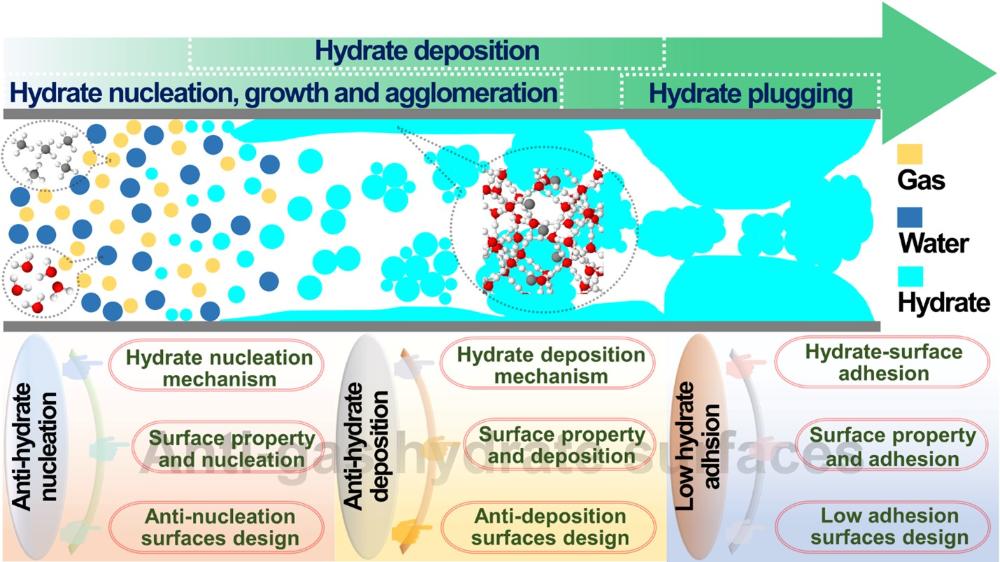

Anti-gas hydrate surfaces: perspectives, progress and prospects

Anti-gas hydrate surfaces: perspectives, progress and prospects

New review article in Journal of Materials Chemistry A, 2022, 10, 379-406.

Mitigating gas hydrate formation and the subsequent pipeline plugging is of critical importance for ensuring safety in exploring and transporting deep-water resources. Until now active methods that use chemicals and thermal energy are mainly applied in tackling the unwanted hydrate accumulation problems. However, these methods not only are costly and but also can result in unavoidable environmental concerns. The rapid developments in surface modification technology and advanced surfaces design offer alternative solutions to mitigate the challenges raised by gas hydrate. In this review, three current research priorities are pinpointed. Firstly, the intrinsic interactions between solid surface-gas hydrate should be scrutinized, which can shed light in solving the complex role of surface properties in hydrate nucleation. Secondly, hydrate deposition mechanisms and surfaces that could suppress hydrate deposition need to be well addressed. Gas hydrate deposition is more than a sequential process of hydrate agglomeration and should be highly related to chemistry/physics of surfaces. Thirdly, hydrate adhesion from nanoscale to continuum scale need to be corelated, which can facilitate the design of surfaces with low hydrate adhesion. After a thorough review on the fundamental relationships between surfaces and hydrate nucleation, deposition and adhesion, anti-gas hydrate surfaces with potentials of suppressing hydrate nucleation, inhibiting hydrate deposition and lowering hydrate adhesion are discussed, aiming to provide a knowledge base for the design and creation of next generation multifunctional hydrate-phobic surfaces.

Anti-gas hydrate surfaces: perspectives, progress and prospects

Anti-gas hydrate surfaces: perspectives, progress and prospects

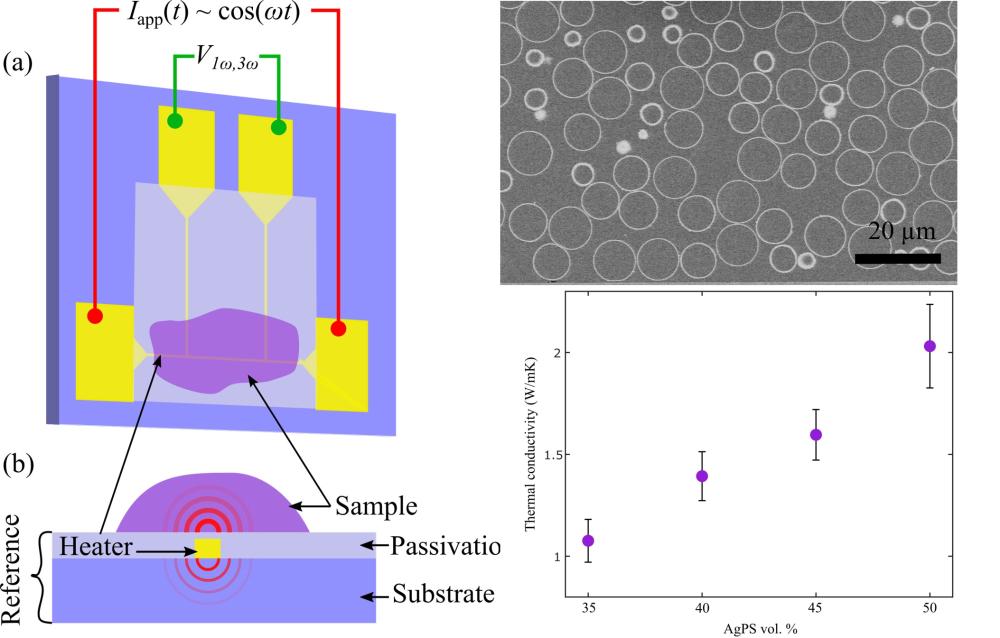

New paper in Journal of Applied Physics, 2022, 131: 125107.

The first 3Ω thermal characterization of a silver coated polymer-sphere based isotropic conductive adhesive (AgPS-ICA). This material has a large potential for use in electronics. Thus, we show a new way of characterizing a material group which is of high significance to many technological applications. This would be of interest to both academic and industry researchers looking for a way of thermally characterizing their samples, as well as those interested in thermal transport on the micro- and nanoscale in general.

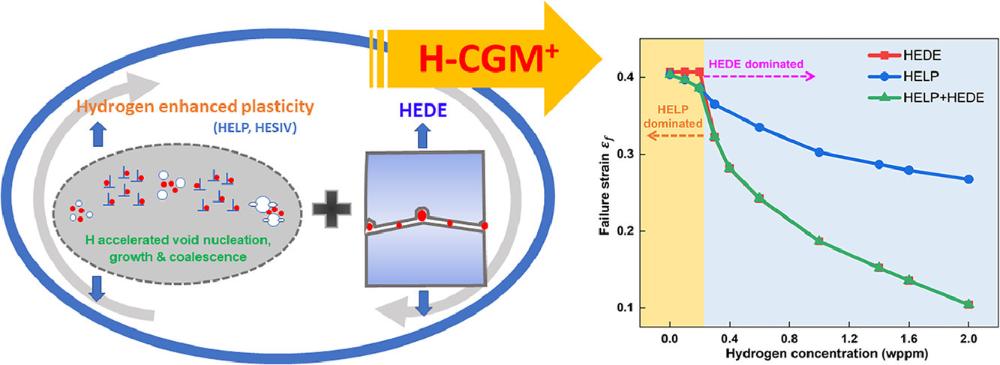

A predictive model unifying hydrogen enhanced plasticity and decohesion

A predictive model unifying hydrogen enhanced plasticity and decohesion

Thanks to the potential of hydrogen as a carbon-free energy carrier, hydrogen embrittlement, a 150 years old problem, has recently received an exponentially growing interest. Historically, hydrogen enhanced plasticity and hydrogen enhanced decohesion have been treated separately. In this work, we for the first time, presented a model which can unify these two failre modes together in a computational framework, capturing the full transition of hydrogen induced ductile to brittle fracture transition.

A hydrogen embrittlement predictive model unifying plasticity and decohesion.

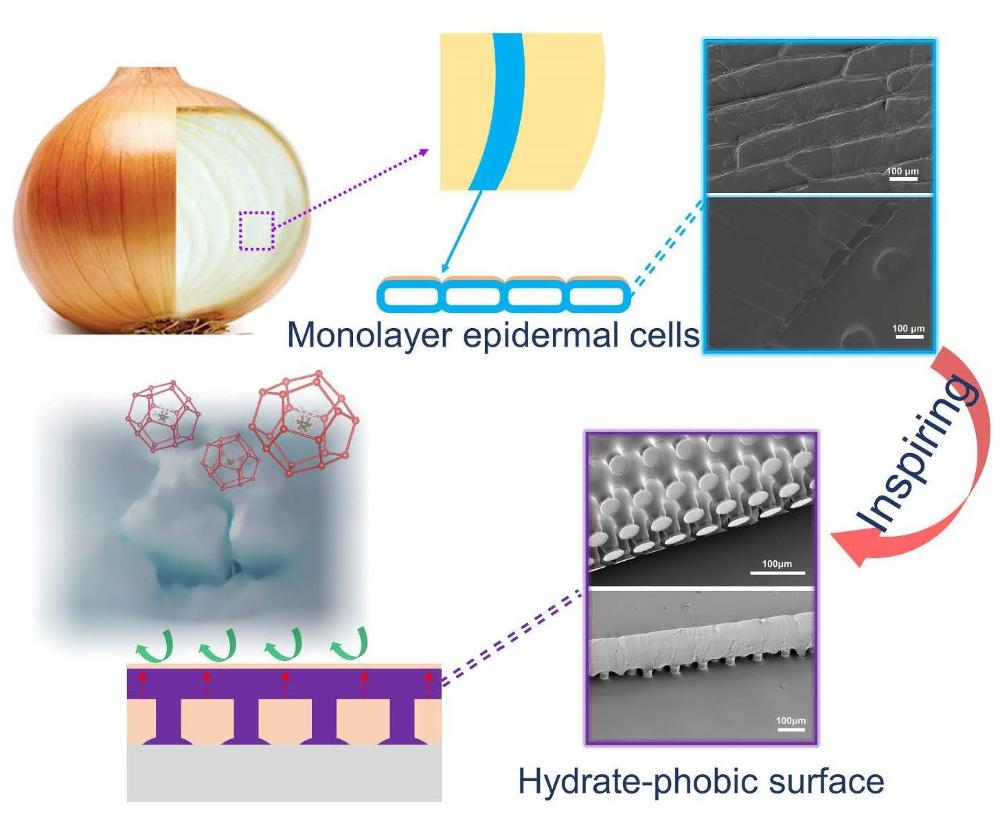

Onion inspired hydrate-phobic surfaces

Onion inspired hydrate-phobic surfaces

New paper published in Chemical Engineering Journal

Hydrate plugging in gas- and oil-production and transport systems has long been a critical challenge. Traditional hydrate mitigation strategies through applying chemicals and thermal destabilization are costly and eco-unfriendly. Passive anti-hydrate surfaces with potential to enable self-removal of hydrates are desired. Surprisingly, thin onion film peeled off from an onion bulb scale is found to have low hydrate adhesion, thanks to the porous structures and the surface cuticle layer. Subsequently, through mimicking the bio-properties of an actual onion film, a hydrate-phobic onion inspired surface with super low hydrate adhesion strength is fabricated. By engineering abundant pores below smooth surface, the onion inspired surface dramatically decreases the cyclopentane (CyC5) hydrate adhesion strength from 95 kPa to 4.7 kPa. The onion inspired surface also maintains super low hydrate adhesion (8.7 kPa) after 20 hydrating/de-hydrating cycles. Furthermore, the performance of this new hydrate-phobic surface is enhanced by integrating a regenerable artificial cuticle layer, which enables even lower hydrate adhesion (2.9 kPa). Therefore, the onion inspired surface can provide alternative solutions for future hydrate mitigation.

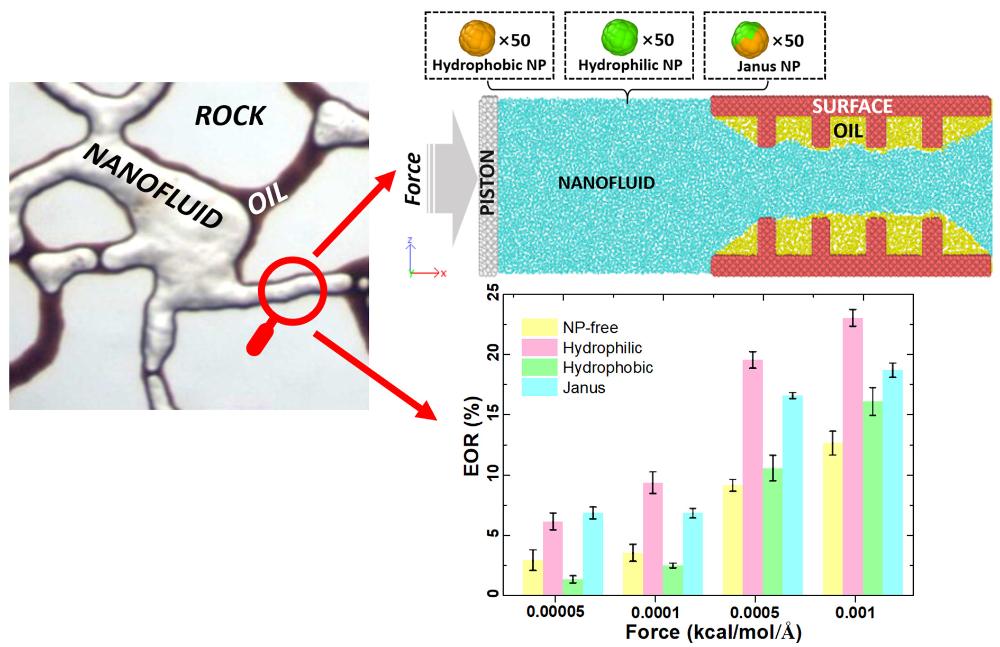

Nanofluids help trapped oil recovery in rough channels

Nanofluids help trapped oil recovery in rough channels

New paper published in Fuel

Nanoparticles hold promising potentials in enhanced oil recovery. The mechanics of nanoparticles interacting with different components in confined nanochannels still awaits in-depth clarification. The reported theoretical studies on nanoscale oil displacement focused on smooth channel, the results of which cannot be directly applied in real reservoir. In the current work, atomistic modeling and molecular dynamics simulations were utilized to investigate the displacement mechanisms of trapped oil in the rough channels by injection of different nanofluids. The results detailed the specific mechanisms of different nanoparticles in displacing residual oil on rough surface under various injection pressure and shed light on the rational design and selection of nanoparticles in practice. Particularly, this work indicated that Janus NPs played multiple roles (extrusion, wettability alteration, and possible structural disjoining pressure), and were effective in oil displacement even under low external pumping force comparable to experimental conditions. With extra analysis on the capillary number, the bright prospects of Janus NPs in the actual reservoirs were further highlighted.

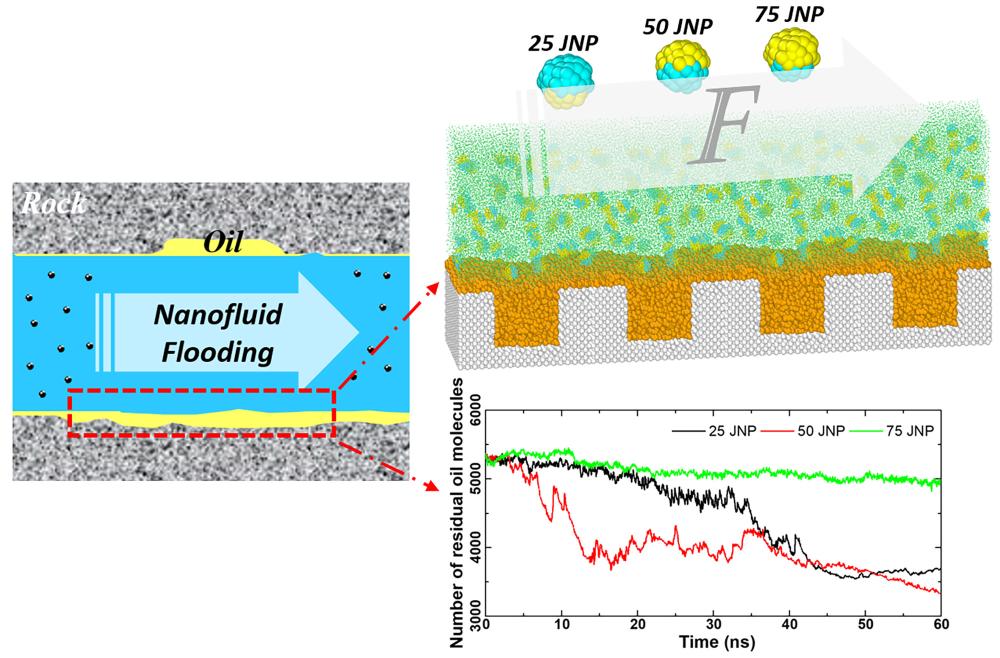

How do Janus nanoparticles displace the trapped oil from rough surface?

How do Janus nanoparticles displace the trapped oil from rough surface?

New paper published in Energy

Janus nanoparticles (NPs) exert the great prospects in enhanced oil recovery (EOR). Their role in displacing the residual oil system inside the confined nanochannels still awaits in-depth clarification. The limited theoretical studies on nanoscale oil displacement focused on the oil-filled smooth channel, the results of which cannot be directly applied in the real reservoir. In the current work, atomistic modeling and molecular dynamics simulations were utilized to investigate the displacement mechanisms of trapped oil in the rough channels by injection of Janus NPs. The results present the oil extraction effects of Janus NPs with varied fractions of nonpolar beads, detail the motion pattern and intrinsic EOR mechanism of Janus NPs and clarify the crucial parameters for optimizing the EOR effect. Particularly, a ‘adsorption invasion process’ is proposed as the dynamics of wettability alteration by Janus NPs for the first time, which highlights the previously concealed crucial successive events in the dynamics of Janus NPs, namely anchoring onto the surface, sweeping trapped oil, pinning at rough edge, and entering the oil-trapping pockets.

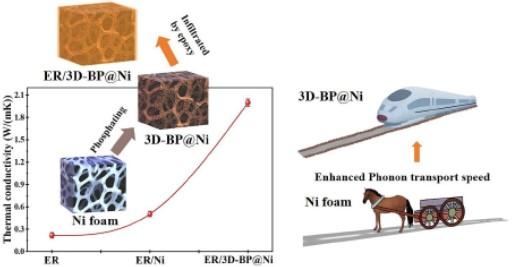

Boron phosphide based 3D network as a new thermal management strategy

Boron phosphide based 3D network as a new thermal management strategy

New paper published in Composites Part B: Engineering

According to the widely accepted theory of thermal conduction pathways, 3D network has been a plausible solution to improve the thermal conductivity of polymer composites. Common 3D thermal conductive networks have often been constructed by complicated methods, such as filtration, ice-template, and self-assembly. However, weak interaction between 3D network carries are noticeable drawbacks for traditional thermal conductive network. To cope with that, in the present work, the continuous and high-quality 3D-BP@Ni network with strong bond has been synthesized by a simple high-temperature treatment process using Ni foam as a template. The good quality and structural integrity endow 3D-BP@Ni network with the high isotropic thermal conductivity. The infiltrated epoxy resin has successfully maintained the continuity and integrity of 3D-BP@Ni to obtain ER/3D-BP@Ni composites. The ER/3D-BP@Ni composite, with strong interfacial bonding between epoxy and 3D-BP, has achieved a high thermal conductivity of 2.01 W/(mK), which corresponds to 908% and 402% enhancement compared to pure epoxy and ER/Ni composite. The CTE of the composite has reached 26.95×10-6/℃, much lower than epoxy of 60.69×10-6/℃ and ER/Ni composite of 59.42×10-6/℃. The designed ER/3D-BP@Ni composite with excellent heat transfer and low CTE greatly improves thermal capability and reduces the mismatch between encapsulated materials and chips.

NML Season's Greetings 2021

NML Season's Greetings 2021

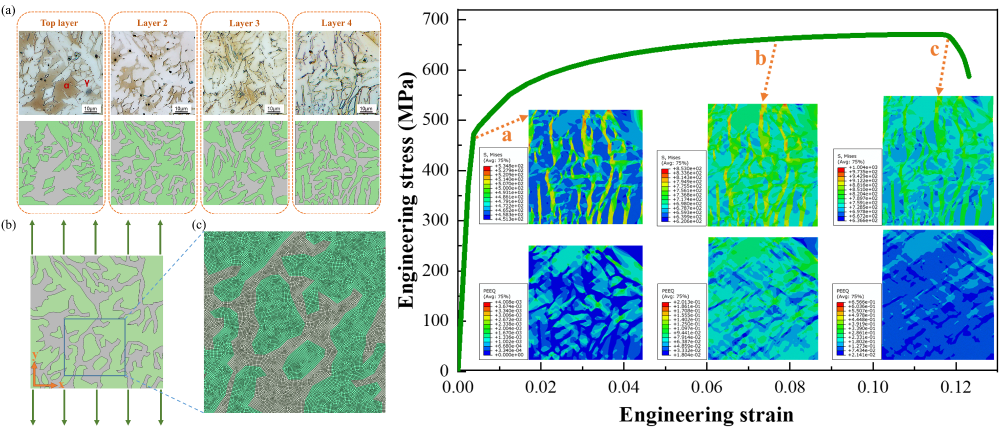

A framework for predicting the local stress-strain behaviors of additively manufactured alloys

A framework for predicting the local stress-strain behaviors of additively manufactured alloys

New paper in Materials Science and Engineering A

We have proposed a framework for characterizing and predicting the local stress-strain behaviors of AM-ed multiphase alloys in the sequential layers, by combing nanoindentation and microstructure-based finite element method (FEM). At first, nanoindentation was utilized to characterize the mechanical properties of the two constituent phases in each layer, including elastic modulus and hardness and the indentation size effect (ISE). Subsequently, the yield strength and hardening exponent of the individual phase were estimated by reverse analysis method. The constitutive behaviors of the individual phase were consequently acquired, which served as input parameters for FEM models. By aid of actual microstructure-based FEM under uniaxial tension, the overall stress-strain behaviors of each layer and the distributions of the stress and strain during the deformation process were investigated. By this method one can not only obtain the local stress-strain behavior, but also illustrate the effects of the constituent phases in multiphase materials.

Latest research shows a correlation between ice adhesion and gas hydrate adhesion

Latest research shows a correlation between ice adhesion and gas hydrate adhesion

Gas hydrate is both a valuable future energy source and a threat to the gas transport. Developing anti-gas hydrate surface is a new strategy to mitigate the hydrate agglomeration challenge.

One question has been asked frequently: Is there any corelation between the ice adhesion and gas hydrate adhesion on a solid surface.

Our recent research shows, yes, there is a simple correlation:

Ice adhesion strength ≈ 5 * Gas hydrate adhesion strength !

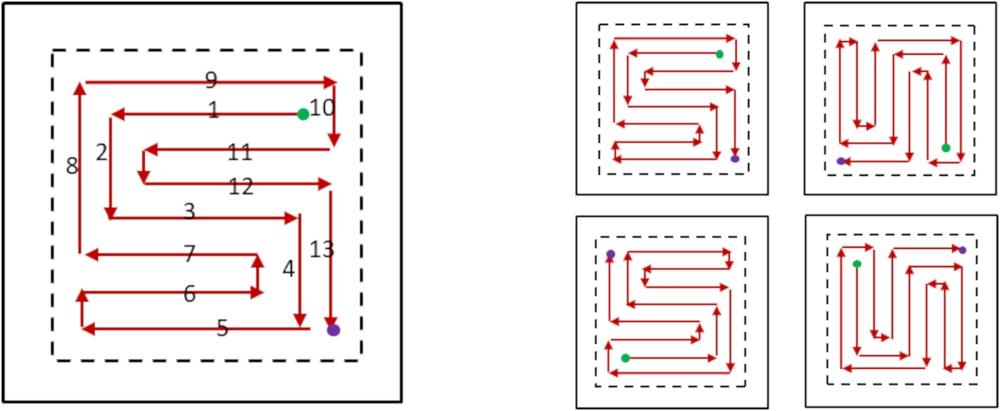

An effective and generic method for evaluating and optimizing the residual stresses in additively manufactured materials

An effective and generic method for evaluating and optimizing the residual stresses in additively manufactured materials

A new publication in Additive Manufacturing

Based on numerical simulations, we first proposed a so-called S printing pattern which theoretically can result in the lowest residual stress in additive manufacturing.

Together with Dr. Jonas Hensel's group at Technische Universität Braunschweig, Germany and Dr. Sakari Pallaspuro at Oulu University, Finland, we experimentally compared the S printing pattern with two other common printing patterns. It was found that the S pattern does not only induce lower residual stresses, but also produces smaller coarse-grain size and less porosity!

Experimental verification shows our novel S printing pattern highly beneficial, better than expected

Experimental verification shows our novel S printing pattern highly beneficial, better than expected

A new paper published in Materials and Design

Based on finite element simulation results, a novel additive manufacturing deposition pattern, called the S pattern was proposed in an early publication. Compared with other existing printing patterns, it was shown numerically that the S pattern produces the lowest residual stresses.

In the new publication appeared in the Materials and Design, an joint experimental verification program led by Dr. Jonas Hensel at Technische Universität Braunschweig, Germany and Dr. Sakari Pallaspuro at Oulu University, Finland has been carried out to compare the performance of three printing patterns.

Experimental results show that the S pattern does not only induce lower residual stresses, but also produces smaller coarse-grain size and less porosity!

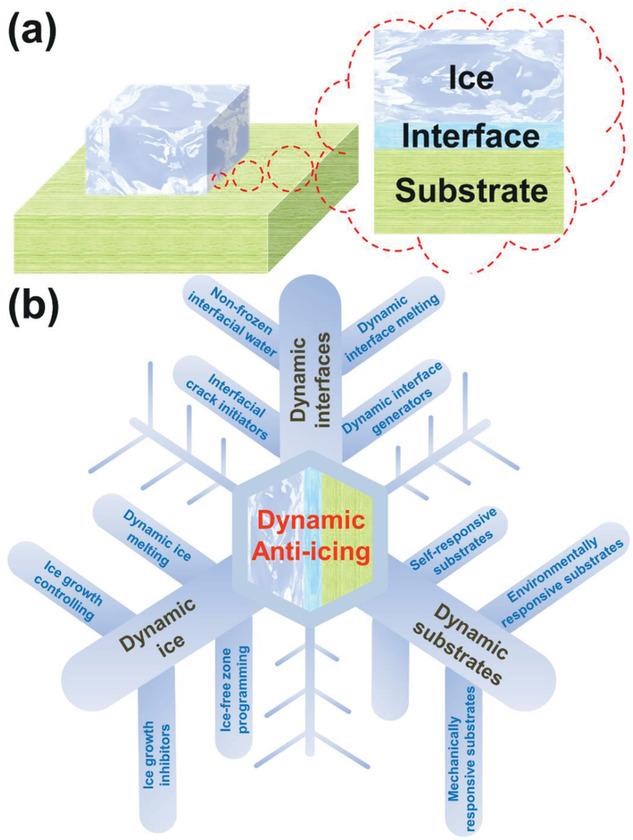

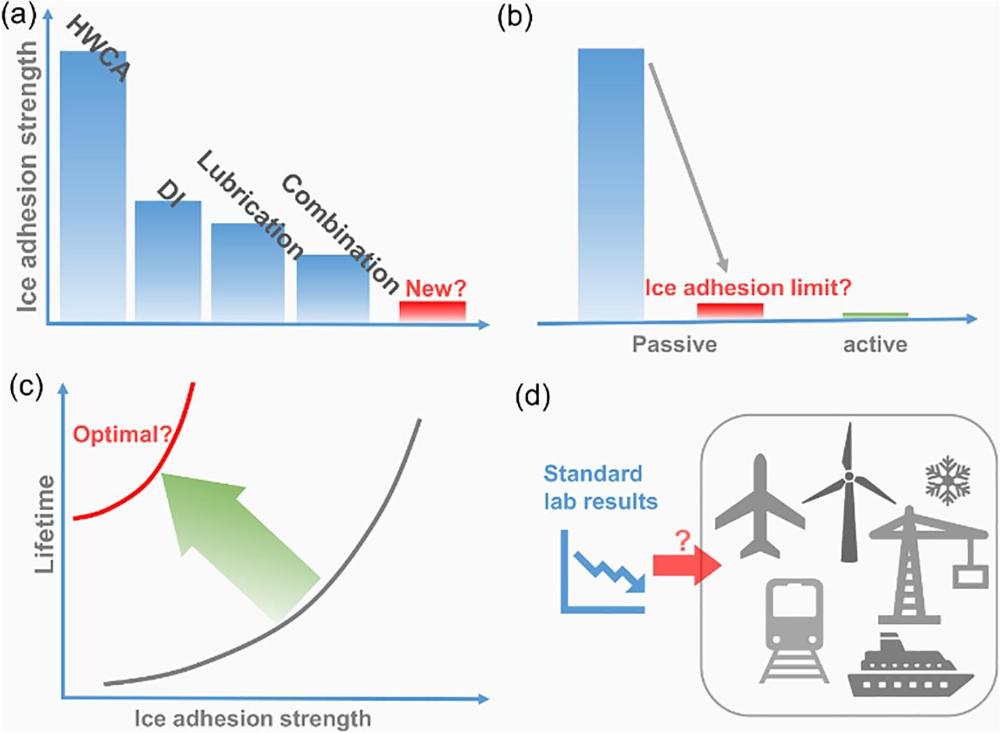

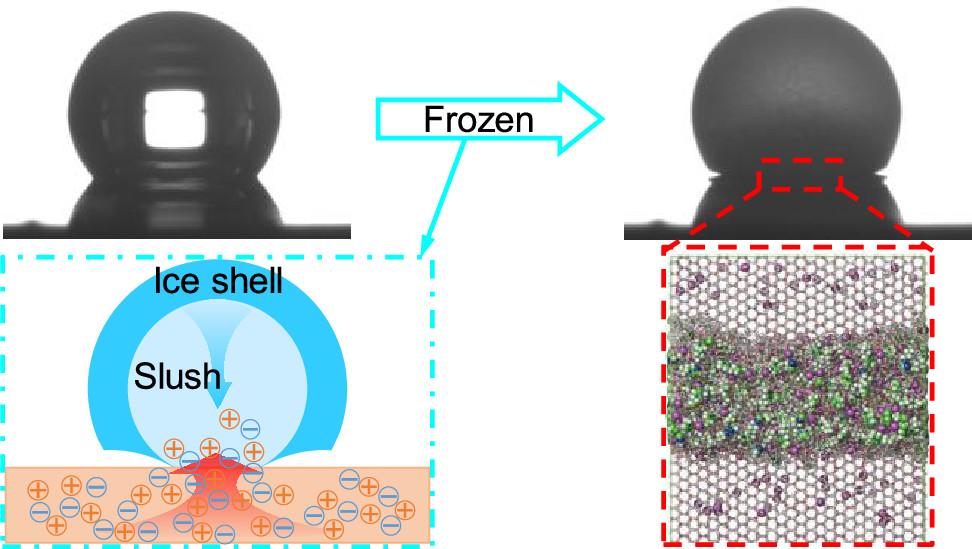

Dynamic Anti-Icing Surfaces (DAIS)

Dynamic Anti-Icing Surfaces (DAIS)

Review article published in Advanced Science

Remarkable progress has been made in surface icephobicity in the recent years. The mainstream standpoint of the reported antiicing surfaces yet only considers the ice–substrate interface and its adjacent regions being of static nature. In reality, the local structures and the overall properties of ice–substrate interfaces evolve with time, temperature and various external stimuli. Understanding the dynamic properties of the icing interface is crucial for shedding new light on the design of new anti-icing surfaces to meet challenges of harsh conditions including extremely low temperature and/or long working time. This article surveys the state-of-the-art anti-icing surfaces and dissects their dynamic changes of the chemical/physical states at icing interface. According to the focused critical ice–substrate contacting locations, namely the most important ice–substrate interface and the adjacent regions in the substrate and in the ice, the available anti-icing surfaces are for the first time re-assessed by taking the dynamic evolution into account. Subsequently, the recent works in the preparation of dynamic anti-icing surfaces (DAIS) that consider time-evolving properties, with their potentials in practical applications, and the challenges confronted are summarized and discussed, aiming for providing a thorough review of the promising concept of DAIS for guiding the future icephobic materials designs.

Phys.org news about our work

Phys.org news about our work

Reference: Zhuo, Y., Xia, Z., Qi, Y., Sumigawa, T., Wu, J., Šesták, P., Lu, Y., Håkonsen, V., Li, T., Wang, F., Chen, W., Xiao, S., Long, R., Kitamura, T., Li, L., He, J., Zhang, Z., Simultaneously Toughening and Stiffening Elastomers with Octuple Hydrogen Bonding. Adv. Mater. 2021, 33, 2008523. https://doi.org/10.1002/adma.202008523

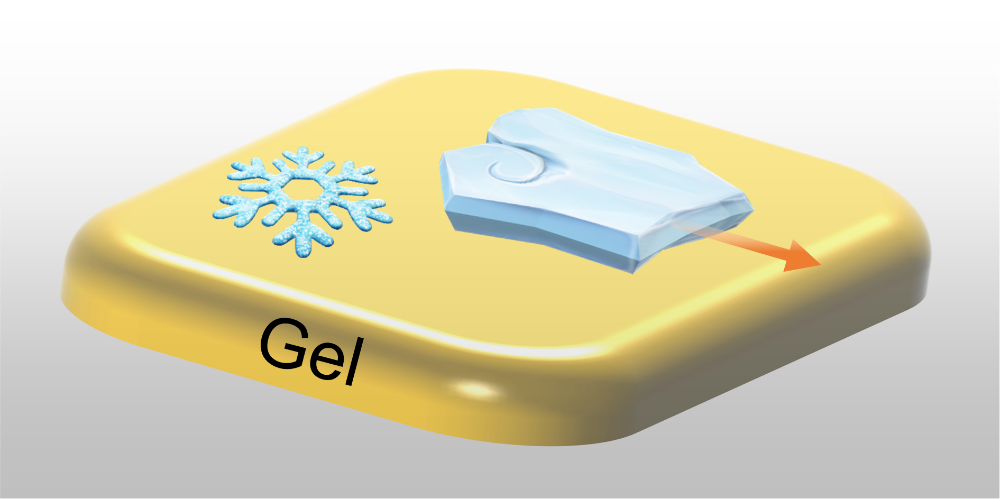

Gels as emerging anti-icing materials

Gels as emerging anti-icing materials

Mini review published in Materials horizons

Gel materials have drawn great attention recently in the anti-icing research community due to their remarkable potential for reducing ice adhesion, inhibiting ice nucleation, and restricting ice propagation. Although the current anti-icing gels are in their infancy and far from practical applications due to poor durability, their outstanding prospect of icephobicity has already shed light on a new group of emerging anti-icing materials. There is a need for a timely review to consolidate the new trends and foster the development towards dedicated applications. Starting from the stage of icing, we first survey the relevant anti-icing strategies. The latest anti-icing gels are then categorized by their liquid phases into organogels, hydrogels, and ionogels. At the same time, the current research focuses, anti-icing mechanisms and shortcomings affiliated with each category are carefully analysed. Based upon the reported state-of-the-art anti-icing research and our own experience in polymer-based anti-icing materials, suggestions for the future development of the anti-icing gels are presented, including pathways to enhance durability, the need to build up the missing fundamentals, and the possibility to enable stimuli-responsive properties. The primary aim of this review is to motivate researchers in both the anti-icing and gel research communities to perform a synchronized effort to rapidly advance the understanding and making of gel-based next generation anti-icing materials.

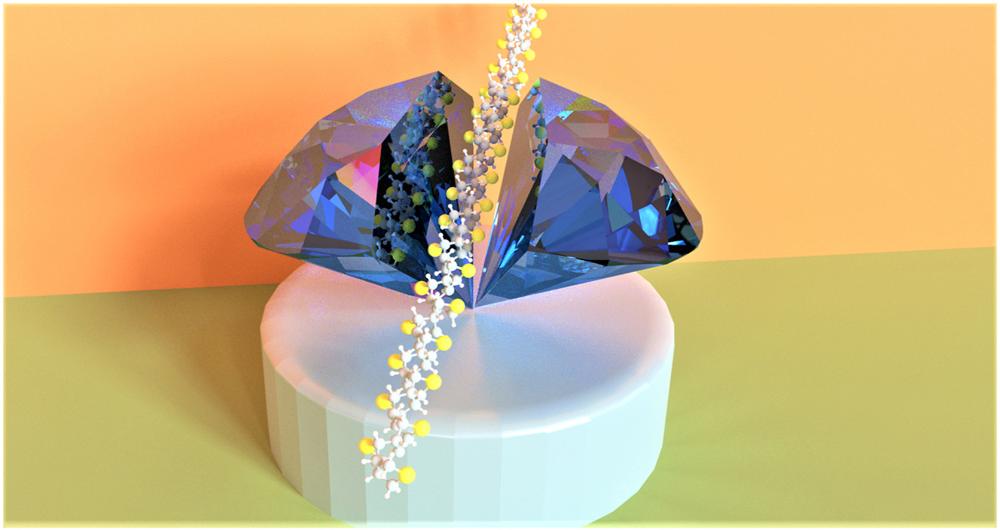

Nanomechanics of ultra-thin carbon sulfur nanothreads

Nanomechanics of ultra-thin carbon sulfur nanothreads

A new paper published in Carbon

Carbon sulfur nanothreads (CSNTs) mainly composed of two chiral long alkane chains have been recently fabricated from thiophene by a pressure-induced phase transition in low-temperature, but their mechanical properties remain unexplored. Here, the critical roles of morphology and temperature on the tensile characteristics of CSNTs are for the first time examined using molecular dynamic simulations with a first-principles-based ReaxFF forcefield. It is revealed that CSNTs exhibit high tensile Young's modulus, high tensile strength and excellent ductility, and their tensile properties are morphology and temperature dependent. Morphologically, atomic arrangement with various configurations makes every CSNTs possess unique mechanical properties. Thermally, as temperature varies from 1 to 1500 K, CSNTs become mechanically weakened. In comparison with conventional diamond nanothreads (DNTs) and carbon nitride nanothreads (CNNTs), CSNTs show distinct axial elongation mechanisms, with relatively insignificant changes in chemical bond orders and bond length in the skeleton prior to the final rupture. Instead, the stretching of bond angle and dihedral angle mainly contribute to the global axial elongation, while the torsional deformation is limited due to their perfect global symmetry in the configuration. This study provides fundamental insights into the mechanics of ultra-thin CSNT structures.

Hydrogen-induced transgranular to intergranular fracture transition

Hydrogen-induced transgranular to intergranular fracture transition

A new paper published in Scripta Materialia

The manuscript demonstrates the direct transgranular to intergranular fracture transition process controlled by hydrogen-influenced plasticity, by scrutinizing the tensile responses of Ni Σ5(210)[001] GB with varied hydrogen concentration using atomistic modeling. Compared with the Σ3 coherent twin GB which traps nearly no H atoms, H will form an atmosphere at the Σ5 GB due to the high trapping energy and excess volume and induce a higher initial local stress. In the case without H, less stress is built up at the Σ5 GB region during deformation, which leads to transgranular fracture. In contrast, H suppresses the stress-releasing ability of the Σ5 GB, which causes a local stress concentration and promotes local plasticity on the GB. This further leads to early dislocation emission, severe twinning evolution, increased number of vacancies and thus enhanced nanovoiding on the GB. The growth of nanovoids with H finally completes the transgranular to intergranular-fracture transition. These findings enrich our knowledge of hydrogen-induced intergranular fracture at the microscale.

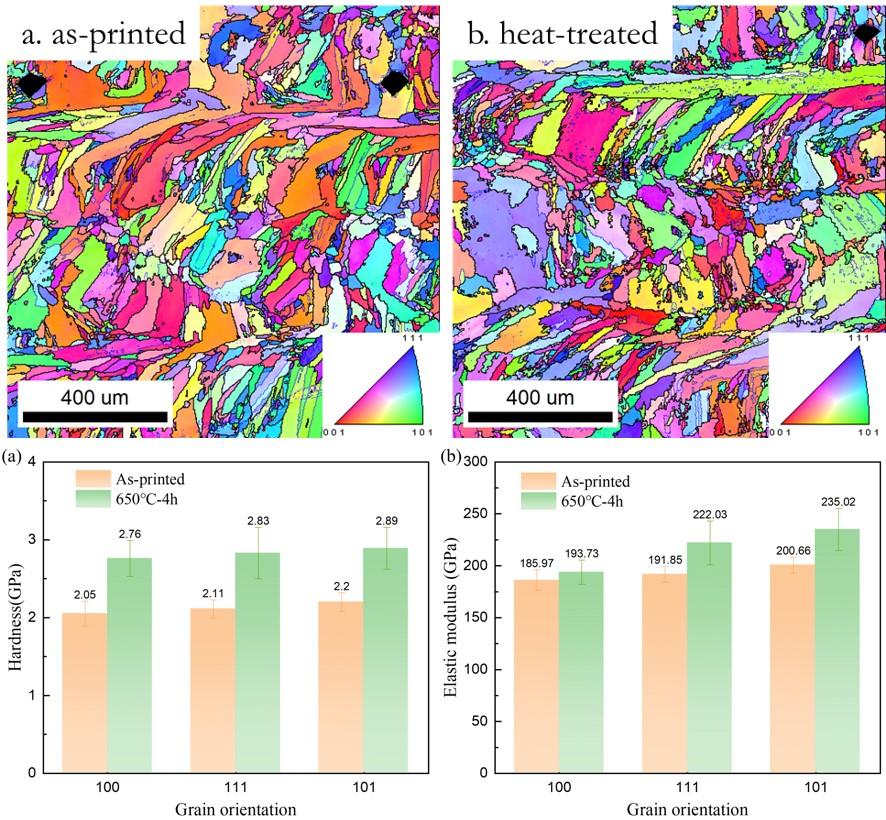

Microstructure and nanomechanical behavior of additively manufactured high entropy alloy

Microstructure and nanomechanical behavior of additively manufactured high entropy alloy

A new paper published in Materials Science and Engineering A

The microstructure and crystallographic orientation-dependent nanomechanical characteristics of an additively manufactured (AM-ed) high-entropy alloy (HEA) were investigated by aid of nanoindentation and SEM. Furthermore, the effect of heat treatment on AM-ed HEA was explored by comparing with as-printed HEA. Interestingly, it is found that the grain {101} has the highest hardness and elastic modulus, whereas the creep resistance of grain {111} is the greatest, with the indicators of the creep mechanism showing lattice diffusion is the dominant mechanism. Heat treatment in the current study can increase the hardness and elastic modulus but decrease the creep resistance slightly. This work elucidates the grain orientation dependence on nanomechanical properties and the role of heat treatment, and sheds light on the nanoscale creep behavior and the corresponding creep mechanisms in the AM-ed HEA.

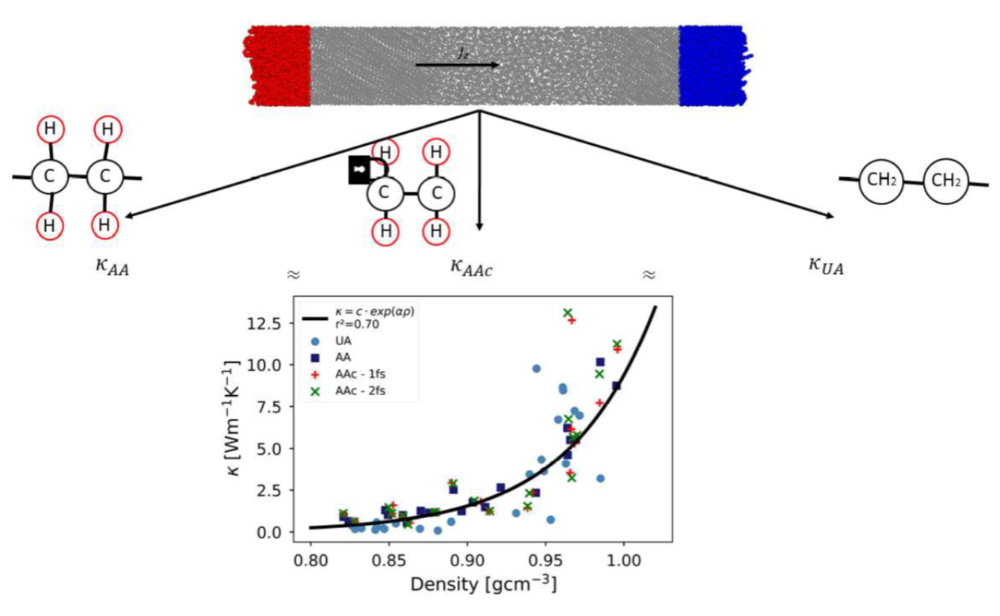

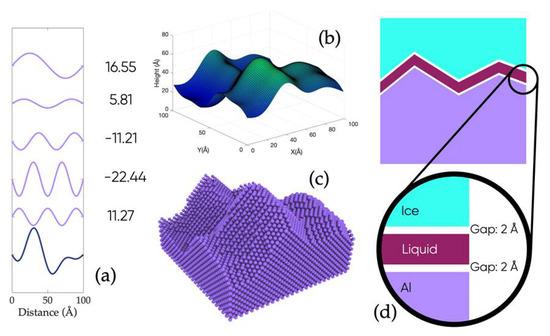

The effect of forcefields on thermal transport in polymers

The effect of forcefields on thermal transport in polymers

The local structure and heat transfer properties (thermal conductivity and interfacial conductance) in model semi-crystalline polyethylene (PE) are studied by non-equilibrium molecular dynamics. Three different force fields with different levels of detail (all-atom, all-atom with constraints, and united-atom) are compared. We find that the structure of the model PE is significantly influenced by the choice of force field. The united-atom force field results in a reduced overall crystallinity and an over-idealized organization of the polymer chains, compared to the all-atom force fields. We find that thermal transport properties are not greatly influenced when structural effects are taken into consideration, and our results suggest that united-atom models can be used to study heat transfer properties of model PE, with decreased computational cost.

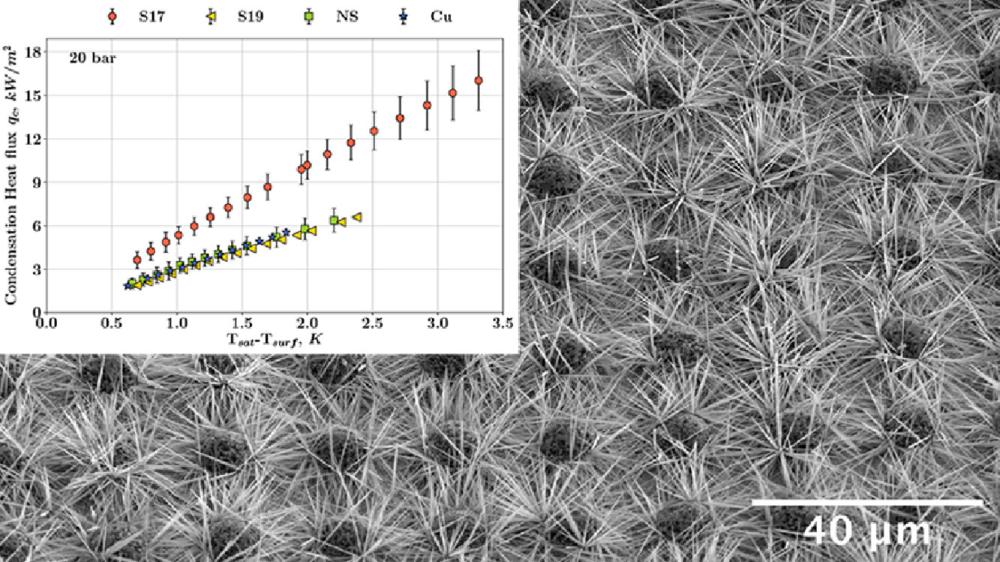

CO2 condensation heat transfer on structured surfaces

CO2 condensation heat transfer on structured surfaces

New papers published in

International Journal of Heat and Mass Transfer

Experimental Thermal and Fluid Science

The experimental method and setup for determining the heat transfer coefficient under CO2 condensation is developed and validated. Condensation heat transfer coefficient of CO2 on smooth surfaces of Cu, Al and stainless steel as well as hierarchical surfaces of Cu based micro and nanostructures have been investigated. It is found that the heat transfer coefficient increases with increasing the saturation pressure and increased surface area. The best of the structured surfaces resulted in a heat transfer coefficient 66% higher than that of the unstructured surface.

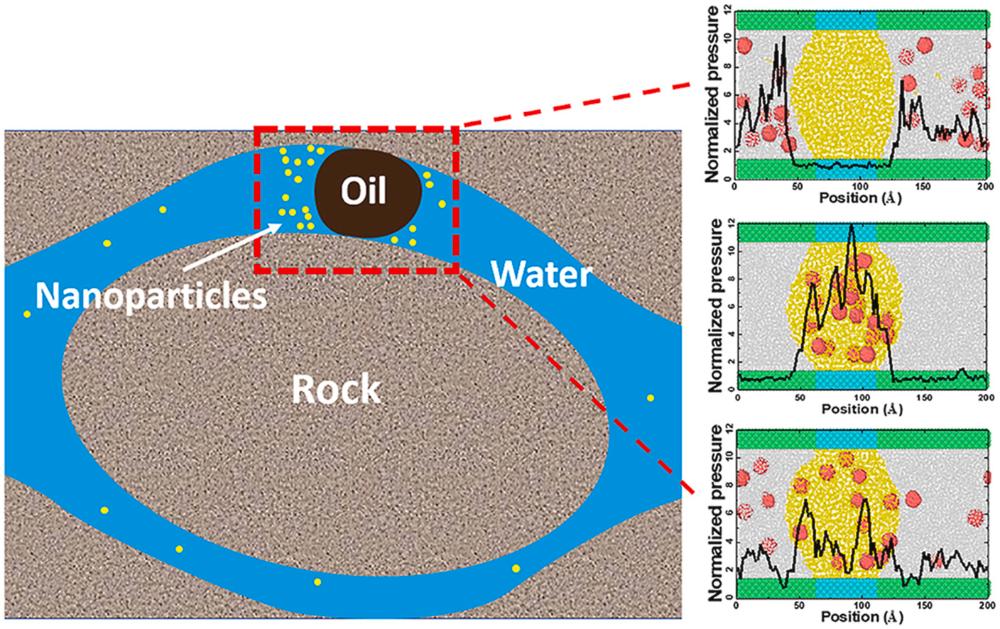

Molecular dynamics simulation reveals structural disjoining pressure

Molecular dynamics simulation reveals structural disjoining pressure

Nanoparticles hold promising potentials in enhanced oil recovery. The mechanics of nanoparticles interacting with different components in confined nanochannels still awaits in-depth clarification. In the current work, atomistic modeling and molecular dynamics simulations were utilized to investigate three different nanoparticle dispersion patterns in nanochannels with trapped oil droplets, namely nanoparticles favoring in water, in oil, and in both phases. The special focus of this study is to detail the local pressure in the nanochannels induced by the injections of nanoparticles. The results reveal the key effects of different nanoparticles on altering the atomistic mechanics in the complex nanofluid system and shed light on the rational design and selection of nanoparticles in practice. Particularly, the local pressure in the three-phase contact area triggered by hydrophilic nanoparticles was found to feature the famous structural disjoining pressure, which supplied supporting evidences to the former continuum medium based analytical study from the atomistic level for the first time.

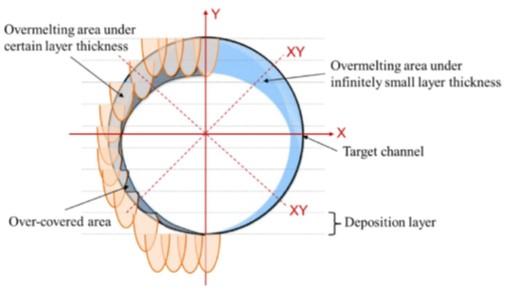

A novel method for Improving Dimensional Accuracy of Additively Manufactured Thin Channels

A novel method for Improving Dimensional Accuracy of Additively Manufactured Thin Channels

A new paper published at International Journal of Precision Engineering and Manufacturing-Green Technology

Powder-bed fusion additive manufacturing technology makes it possible to produce parts with complicated geometry and high accuracy. However, dimensional deviation caused by powder overmelting and dross formation is still a challenge for manufacturing thin channels. In this study, the origins of the overmelting of printed thin channels were analyzed and a concept called “melting cell” is proposed to describe and quantify the geometric error. Based on the geometrical relationship between the melting cell and target channel, a method for predicting and optimizing the fnal geometry of thin channels is outlined. In order to verify the method, geometries of thin horizontal circular channels in various sizes are studied as examples. The predicted results by the proposed method show a remarkable agreement with available experimental results. Moreover, a new egg-shaped compensated design, which is able to improve the dimensional accuracy of thin horizontal circular channels, is presented. The proposed method is simple yet very efective. It can be easily extended to the manufacturing of thin channels with various shapes, materials, and different powder bed fusion processes.

Simultaneously toughening and stiffening elastomers with octuple hydrogen bonding

Simultaneously toughening and stiffening elastomers with octuple hydrogen bonding

Paper published by Advanced Materials (Impact Factor of 27.4).

Current synthetic elastomers suffer from the well‐known trade‐off between toughness and stiffness. By a combination of multiscale experiments and atomistic simulations, a transparent unfilled elastomer with simultaneously enhanced toughness and stiffness is demonstrated. The designed elastomer comprises homogeneous networks with ultrastrong, reversible, and sacrificial octuple hydrogen bonding (HB), which evenly distribute the stress to each polymer chain during loading, thus enhancing stretchability and delaying fracture. Strong HBs and corresponding nanodomains enhance the stiffness by restricting the network mobility, and at the same time improve the toughness by dissipating energy during the transformation between different configurations. In addition, the stiffness mismatch between the hard HB domain and the soft poly(dimethylsiloxane)‐rich phase promotes crack deflection and branching, which can further dissipate energy and alleviate local stress. These cooperative mechanisms endow the elastomer with both high fracture toughness (17016 J m−2) and high Young's modulus (14.7 MPa), circumventing the trade‐off between toughness and stiffness. This work is expected to impact many fields of engineering requiring elastomers with unprecedented mechanical performance.

Reconfigurable Mechanical Anisotropy in Self‐Assembled Magnetic Superstructures

Reconfigurable Mechanical Anisotropy in Self‐Assembled Magnetic Superstructures

A new paper published at Advanced Science (Impact Factor of 15.8)

Through a comprehensive Monte Carlo investigation, this study demonstrates how the mechanical properties of self‐assembled magnetic nanocubes can be controlled intrinsically by the nanoparticle magnetocrystalline anisotropy (MA), as well as by the superstructure shape anisotropy, without any need for changes in structural design (i.e., nanoparticle size, shape, and packing arrangement). The new concepts developed here pave the way for the experimental realization of smart magneto‐micromechanical systems (based, e.g., on the permanent super‐magnetostriction effect illustrated here) and inspire new design rules for applied functional materials.

Machine Learning Based Prediction of Nanoscale Ice Adhesion on Rough Surfaces

Machine Learning Based Prediction of Nanoscale Ice Adhesion on Rough Surfaces

Our group is truly the first one to develop machine-learning based tool for predicting nanoscale ice adhesion. See the publication here.

NML Season's Greetings 2020

NML Season's Greetings 2020

Self-emulsifying and demulsification of water-in-oil microemulsion droplet

Self-emulsifying and demulsification of water-in-oil microemulsion droplet

Stability, deformation and rupture of Janus oligomer enabled self-emulsifying water-in-oil microemulsion droplet

Physical Chemistry and Chemiscal Physics, DOI: 10.1039/D0CP03092A

We have investigated the spontaneous emulsification process from a water, oil and surfactant mixture to form a single microemulsion droplet. By applying counter forces on the water core and the surfactant shell, the mechanical stability of microemulsion droplets was probed at different ambient temperatures. A strengthening response and a softening regime before and after a temperature-dependent peak force were identified followed by final rupture. The findings contribute to establishing an atomistic view on the previous studies on microemulsion fluids, and provide a general guide to design a stable microemulsion system, such as oil recovery and production, drug delivery, materials fabrication, chemical sensors, wastewater treatment, etc.

Timely data survey on the polysiloxane-based icephobic materials

Timely data survey on the polysiloxane-based icephobic materials

Polysiloxane as icephobic materials – The past, present and the future

Chemical Engineering Journal, 2021, 405: 127088

Perspectives of polysiloxane low-ice adhesion materials research.

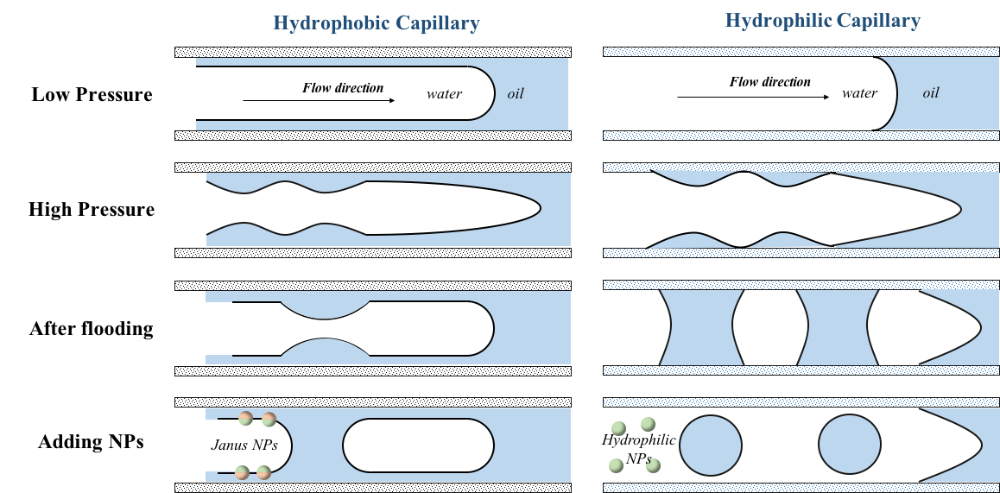

Pressure-induced displacement of nanofluids in confined capillaries

Pressure-induced displacement of nanofluids in confined capillaries

Insight into the pressure-induced displacement mechanism for selecting efficient nanofluids in various capillaries

Environmental Science: Nano, 2020, 7: 2785-2794

Fluids flow in porous media is ubiquitous and has important application in numerous fields, such as groundwater remediation, oil recovery, water purification, etc. Taken the oil recovery as an example, increasing the pumping pressure of injecting fluid can improve the oil recovery. However, as flooding pressure reaches a specific high value, considerable amount of oil would be trapped in the reservoir due to “fingering” phenomenon. How to overcome the “fingering” to increase the production of the residual oil is a hot topic in the research of petroleum engineering. Here we propose two distinct displacement mechanisms. Specifically, reducing the interfacial tension of fluids is beneficial to improve the displacement efficiency in hydrophobic capillary, while increasing viscosity of fluids favours for hydrophilic capillary. Based on the proposed mechanisms, we design three types of nanofluids to improve the displacement efficiency for different capillaries.

Pascal-level ice adhesion surfaces

Pascal-level ice adhesion surfaces

New article by Dr. Tong Li

Self-Deicing Electrolyte Hydrogel Surfaces with Pa-level Ice Adhesion and Durable Antifreezing/Antifrost Performance

ACS Applied Materials & Interfaces, 2020, 12, 35572-35578

We have synthesized the ionic gel (IG) surfaces for everlasting anti-freezing and zero ice adhesion to ice with tuneable anti-icing temperature (down to -48.4 degree C). Moreover, we introduce the concept “deicing time” to evaluate the ice self-removal from the IG surface within 10-100 s. These excellent performances are due that the ions inside the IG diffuse to the interface between IG and water/ice to destroy ice crystals, as demonstrated by both the molecular dynamics simulations and experimental results. In summary, we first provide a possible approach to prevent ice formation and accretion in the long-term.

A novel "S-type" printing pattern developed at NML will yield lowest residual stresses in additive manufacturing of metallic materials

A novel "S-type" printing pattern developed at NML will yield lowest residual stresses in additive manufacturing of metallic materials

Tensile characteristics of carbon nitride nanothreads

Tensile characteristics of carbon nitride nanothreads

New article by PhD candidate Yuequn Fu

The effects of morphology and temperature on the tensile characteristics of carbon nitride nanothreads

Nanoscale, 2020, 12, 12462-12475

We have performed comprehensive investigation on tensile mechanical characteristics of seven experimental synthesized CNNTs by using first-principle based ReaxFF molecular dynamics (MD) simulations. All the CNNTs exhibit unique tensile mechanical properties that change with molecular morphology, atomic arrangement and the distribution of nitrogen in the skeleton. CNNTs with more effective loading covalent bonds at cross-sections are more mechanically robust. The study provides physical insights into the tensile characteristics of CNNTs for the design and application of CNNT-based nanostructures as multifunctional materials.

New ionogel surfaces inhibit ice nucleation, growth and adhesion

New ionogel surfaces inhibit ice nucleation, growth and adhesion

Anti-icing Ionogel Surfaces: Inhibiting Ice Nucleation, Growth, and Adhesion

ACS Materials Letters, 2020, 2: 616-623

We have fabricated an ionogel surface that can not only inhibit the ice nucleation but also the subsequent step, the ice growth. Due to the inhibited ice growth, the ionogel surface enables an unconventional inward ice growth in water droplets from the droplet-air interface, resulting in a spherical cap ice rather than a normal pointy cap ice at cold environment. Both experiments and molecular dynamic simulations confirm that the prepared ionogel surface can efficiently generate an interfacial liquid layer due to the inward ice growth and presence of ionic liquid. Such non-frozen interfacial liquid layer is desired for lowering ice adhesion and preventing ice/frost formation. Consequently, the ionogel surface exhibits unprecedented anti-frost abilities under humid environment (-20 ºC, 60% RH). This is the first surface that can inhibit both ice nucleation and growth!

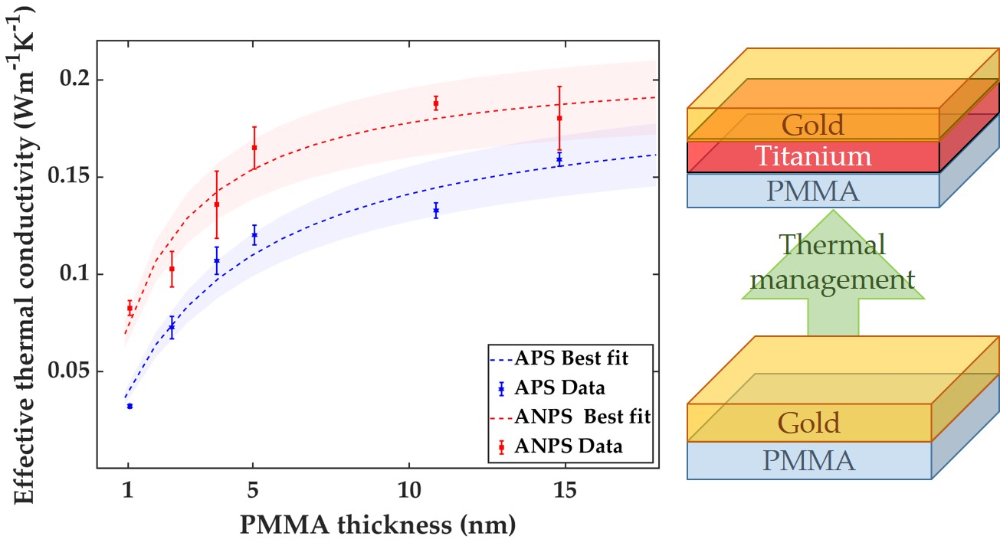

How to enhance the thermal boundary conductance of metal-polymer system

How to enhance the thermal boundary conductance of metal-polymer system

New article by PhD candidate Susanne Sandell

Enhancement of Thermal Boundary Conductance of Metal–Polymer System

Nanomaterials, 2020, 10, 670

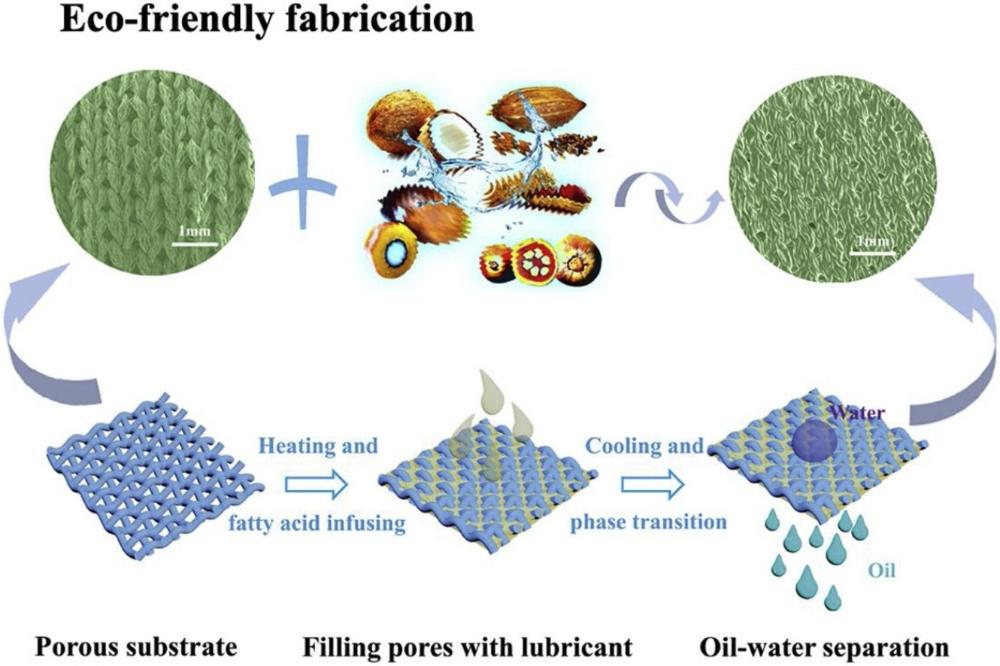

Phase transition lubricant for oil/water separation

Phase transition lubricant for oil/water separation

New article by PhD candidate Feng Wang

Enabling phase transition of infused lubricant in porous structure for exceptional oil/water separation

Journal of Hazardous Materials, 2020, 290, 122176

New Paper published at "Applied Materials Today"

New Paper published at "Applied Materials Today"

NML developed an ultrafast self-healing, highly transparent mechanically durable icephobic coating.

Ultrafast self-healing and highly transparent coating with mechanically durable icephobicity

Applied Materials Today, 2020, 19, 100542

News: No ice, ice, baby!

person-portlet

-

Jun Chen Postdoctoral Fellow

+4745891932 jun.chen@ntnu.no Department of Structural Engineering -

Karl Etienne Dany Druesnes PhD Candidate

+4948900882 karl.druesnes@ntnu.no Department of Structural Engineering -

Håvard Mo Fagersand

+4741085722 havard.m.fagersand@ntnu.no Department of Structural Engineering -

Martha Seim Gunstad PhD Candidate

martha.s.gunstad@ntnu.no Department of Structural Engineering -

Helge Kristiansen

helge@conpart.no Department of Structural Engineering -

Erling Velten Rothmund PhD candidate

erling.v.rothmund@ntnu.no Department of Structural Engineering -

Håvard Rugtvedt PhD candidate

havard.rugtvedt@ntnu.no Department of Structural Engineering -

Paul Jorrit Rübsamen-Von Döhren PhD student

paul.j.r.von.dohren@ntnu.no -

Thorstein Wang PhD student

thorstein.wang@ntnu.no -

Yu Wei Researcher

yu.wei@ntnu.no Department of Structural Engineering -

Kaizheng Yang PhD Candidate

kaizheng.yang@ntnu.no Department of Structural Engineering -

Yifan Zhang

yifan.zhang@ntnu.no Department of Structural Engineering -

Yunqi Zhang PhD Candidate

yunqi.zhang@ntnu.no Department of Structural Engineering -

Xinshu Zou PhD

xinshuz@ntnu.no