Materials - MTP

Manufacturing

The Manufacturing research group focuses on sustainable manufacturing processes in three main areas: Metal forming; AM, subtractive and manufacturing metrology; Joining, welding and assembly. This group is closely linked to the NTNU Aluminium Product Innovation Centre (NAPIC), MANULAB - national infrastructure and the Gemini Center for Metal Forming.

Metal forming

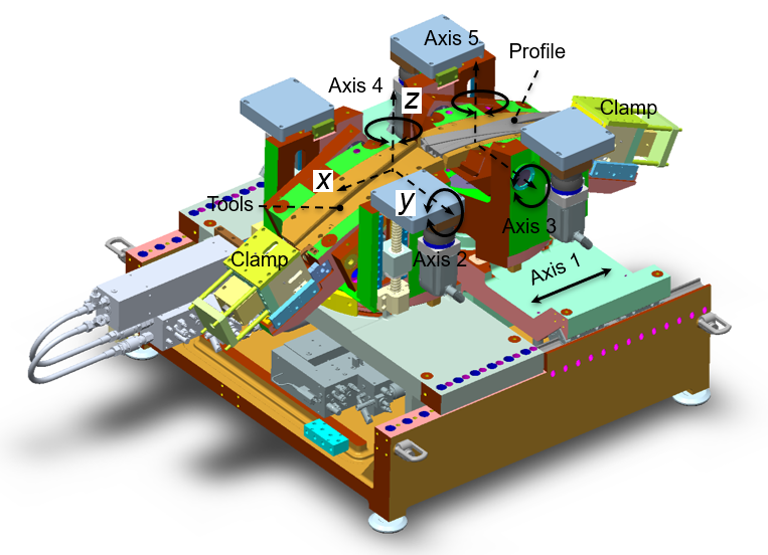

In recent years, the demand for lightweight materials, particularly aluminum, has surged as part of a broader push toward more sustainable solutions. This trend is especially evident in electric mobility. Norway has a long history of a key player in the aluminum value chain. The Manufacturing group's research and educational activities are centered around not only recycling and re-use of extruded aluminum products but also incorporate traditional bending methods such as rotary draw bending, roll bending, and compression Bending. Furthermore, the group is actively exploring innovative processes like 3D flexible rotary stretch forming.

|

|

AM, subtractive and manufacturing metrology

Joining, welding and assembly

Materials

Research focus

Applied materials engineering and advanced surfaces – from materials production to properties and components.

Specifically focused on:

-

Fundamental understanding of materials properties on multi-scale level (from nano to macro), both modelling and experiments.

-

Applied nanotechnology and chemistry: developing new materials (ceramic, metallic, cermets, lubricants and additives) and nanostructured surfaces, as well as methodologies for multi-physical characterization of material properties.

-

Manufacturing and testing materials, components and structures made of polymers and composites: modelling and utilizing material properties in design, optimization of production methods and processes. Long-term properties, inspection and joints.

-

Develop smart solutions for Integrity Management: advanced condition monitoring combined with modelling.

Competence research areas

The activities in the research group materials are split into seven different competence research areas:

-

Polymers and composites

-

Advanced surfaces and materials

-

Corrosion and corrosion protection

-

Mechanical engineering

-

Hydrogen and nanomechanical testing

-

Tribology and lubrication

-

Computational materials and artificial intelligence

Composites and polymers

Composite and polymer materials are being used more and more, both in general and in the offshore industry. Thermoset, thermoplastic and natural polymers of studied. We focus on long-term properties, damage mechanisms, condition monitoring and connections between different materials. Norway’s long coast and the large oil and gas industry mean that it is natural to focus on offshore applications for composites. Examples are flexible pipes, risers, anchoring systems, pressure containers and maritime vehicles. The materials group is also active in renewable energy and works on offshore wind energy, pressure containers for hydrogen and light-weight design of transport solutions.

We focus especially on:

- practical methods for calculating properties of composite laminates and wound products

- connections between different materials: bolt connections and glued connections

- long-term properties of polymers and composites in demanding environments

- materials for insulation and buoyancy in deep sea

We value the interaction between numerical calculations (FEA) and experimental testing. Good knowledge of FEA is an important factor for the job prospects of our students. Our research results contribute to development of design standards, methods for choice of materials, and introduction of new components.

Corrosion and corrosion protection

Because the maritime industry, fish farming and oil & gas industry in Norway are faced with very challenging environment for materials, corrosion and corrosion protection has been an important research area during the last 30 years. The research activities include, but are not limited to:

- Corrosion properties of corrosion resistant alloys in marine and process environment – including effect of microstructure and production method.

- Development of test methods.

- Development/modification of coatings (organic/metallic) for atmospheric conditions and exposure to fluids including quantification of properties.

- Development of condition monitoring systems.

- Cathodic protection to prevent corrosion.

The group has had a focus on development and use of modern and new test techniques to be able to achieve a better basic understanding of the effect of chemical composition, microstructure and production method on corrosion properties of materials. With good interaction with the industry, most of the projects are based on industry problems and needs.

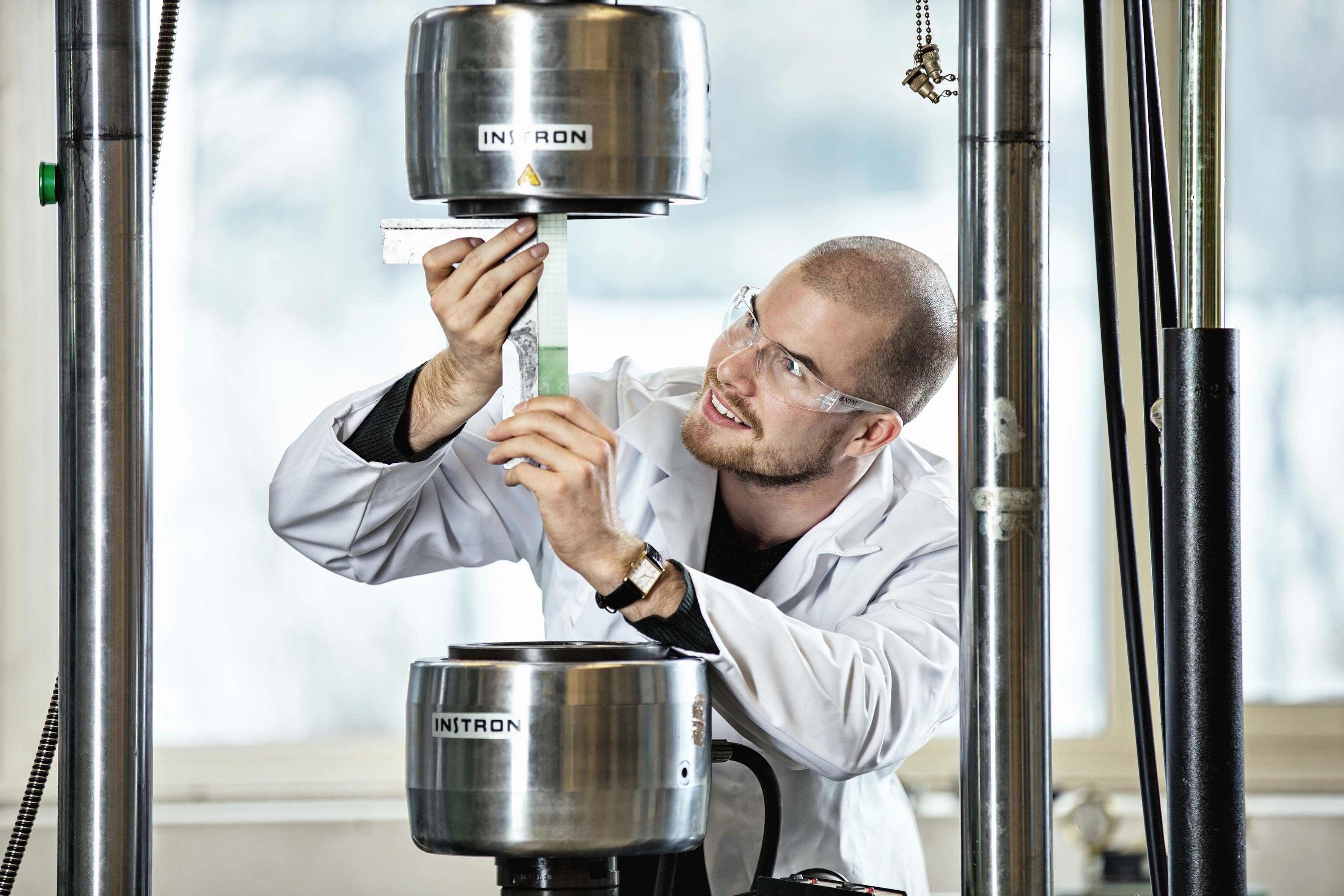

Mechanical Engineering

Research on materials aspects of mechanical engineering is performed in the following areas: application and theoretical aspects of fatigue of technical components made from steel, cast iron, and aluminium alloys; FEM modelling and design of components in various applications (pumps, hydraulic systems, motors, etc). Both testing and modelling aspects of mechanical components are covered.

Research on fracture mechanics is also conducted and focuses on pipelines and offshore constructions. The challenges in industry in recent years have shown a need for a strain-based design of pipelines and use of materials in extreme environments (arctic conditions, hydrogen and other environmental interactions, corrosion, etc). There is a growing need for safe use of materials under extreme conditions.

Hydrogen and nanomechanical testing

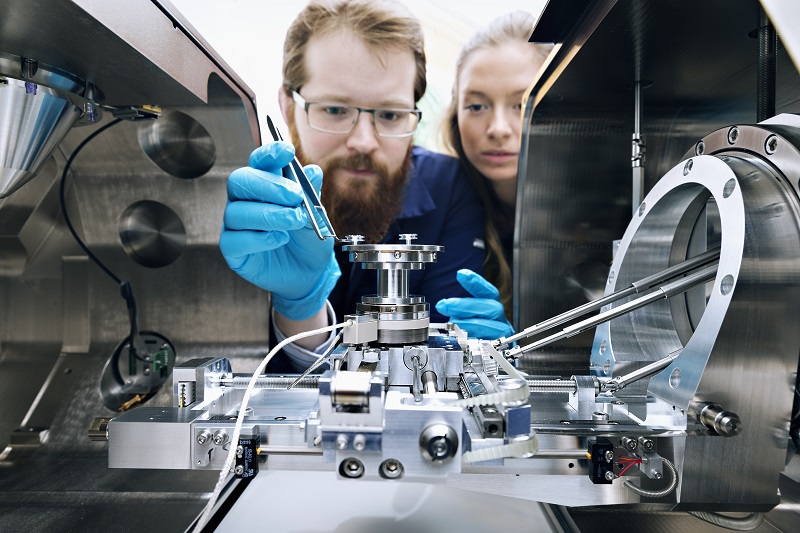

We have built up a well-equipped nanomechanical laboratory with ESEM, AFM, Nanoindenter, and Picoindeter enabling the exploration of hydrogen-assisted damage evolution at multiscale levels (from meso to nano), development of advanced in-situ/ex-situ testing and characterization techniques, and design of hydrogen resistant metallic materials. As research tool, we also use Ga-FIB at NTNU NanoLab and Plasma-FIB at MTP. The research activities include, but are not limited to:

- Meso-scale tensile/fatigue/creep testing and micromechanical testing inside ESEM.

- Nanoindenter-driven microcantilever bending, micropillar compression, and nano-indentation testing under in-situ hydrogen environment.

- In-situ SPM characterization of microstructure evolution under in-situ hydrogen environment.

- High-resolution material characterization using ECCI, TKD, Tof-SIMS, and 3D-EBSD.

The materials being investigated cover a wide range of high strength steels, nickel-based alloys, high-entropy alloys, and titanium alloys for automotive, oil and gas, and hydrogen energy applications.

Tribology and lubrication

The research in tribology and lubrication covers all aspects of tribology from modelling/theory to experimental. We have a very well-equipped tribology laboratory and access to other advanced infrastructure at NTNU. This research area focuses on the following topics:

- Tribocorrosion of passive metals and alloys, from biological to energy systems.

- Applied tribological problems related to dry and lubricated systems.

- Modelling tribology from nano-to-meso scale, with focus on 2D materials, electrolytes, and polymers. We use atomistic and coarse-grained molecular-dynamics simulations.

- Fundamental research on nanotribology using simple models to understand basic mechanisms.

- Nano-tribology with focus on experimental techniques such as AFM (liquid, dry and electrochemical) and QCM (including electrochemical QCM). These studies are combined with micro- and macro-tribological tests.

- Lubricants and lubrication, with special focus on environmentally acceptable lubricants (EALs) and green tribology. In this area, we perform research on developing new lubricant formulations for the green shift. To reach the UN Sustainable Development Goals by 2030, EALs will be a requirement in many fields.

Advanced surfaces and materials

The main goal of the research in this area is to offer solutions for degradation of materials. Degradation of materials usually starts at the surface, with corrosion, wear, or fatigue. Surface engineering is key to improve the lifetime of materials providing a protection to the bulk. In addition, we consider functionality, combining multifunctional surfaces. In this area, the group is constantly developing new solutions for wear and corrosion-related problems, both at fundamental and applied levels. The group has developed, patented and commercialized surface engineering solutions for multiple purposes, especially in the field of thermal spray.

In addition to surface engineering, surface chemistry plays a role both in lubricant formulation and degradation of materials. Understanding the surface mechanisms and phenomena across scales (from nano-to-macro) is crucial to solve the degradation of materials to design and optimize surface solutions.

This research area focuses on the following topics:

- Thermal spray coatings and feedstock materials. We are well equipped with a powder lab to develop our own feedstock powders, both for thermal spray and additive manufacturing.

- Organic coatings for corrosion protection and drag performance in offshore installations and shipping industry.

- DLC coatings for lubricated systems, with focus on optimizing the coating-lubricant additive pair.

- Surface solutions for civil infrastructure.

Computational materials and artificial intelligence

With the ever-increasing availability of computing power, computers are becoming more and more important in many aspects of our lives, including research. Simulations are becoming a powerful tool for understanding and predicting the behaviour of materials in circumstances where experiments are difficult or cannot provide enough information. We use simulations as a tool to support experiments, develop new materials, design of components, and to develop understanding of basic mechanisms. We use High-Performance Computing facilities in our department, at NTNU, and national clusters through Sigma2.

- FEM

- Molecular Dynamics (atomistic and coarse-grained): transport properties and degradation mechanisms. Transport in materials such as diffusion and friction can lead to changes over time that produce wear, damage, degradation, and loss of function. There is no general formalism to describe this. To understand transport and degradation, we use molecular dynamics simulations to link microscopic dynamics of particles to macroscopic averages.

Manufacturing

Head of Department Torgeir Welo

Associate Professor Bjørg Margrethe Granly

Associate Professor Nima Razavi

Associate Professor Sigmund Arntsønn Tronvoll

Associate Professor Sindre Wold Eikevåg

Materials

Polymers and composites

Associate Professor Nils Petter Vedvik

Advanced surfaces and materials

Angelika Brink

Corrosion and corrosion protection

Ole Øystein Knudsen

Mechanical engineering

Associate Professor Bjørn Haugen

Associate Professor Nils Petter Vedvik

Hydrogen and nanomechanical testing

Tribology and lubrication

Computational materials and artificial intelligence

Associate Professor Bjørn Haugen