BRU21 Academy

BRU21 Academy

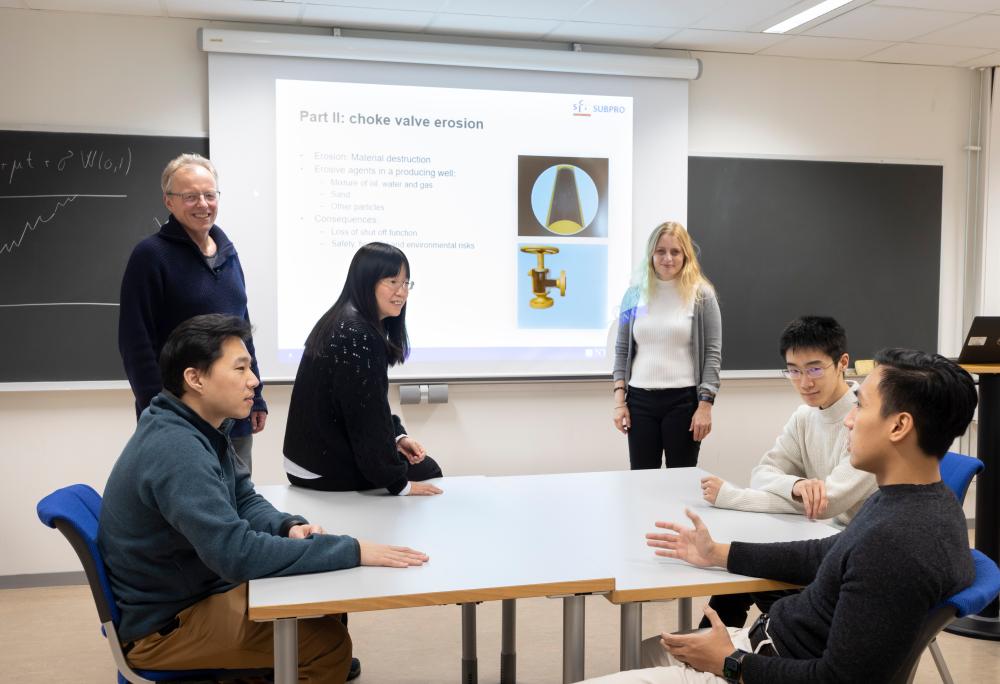

The BRU21 team has established a continuing education master program in Digitalization and Automation where the courses are aligned with the BRU21 research.

NTNU runs several continuing education programs, please see the continuing education pages at NTNU for a list of programs. Among these programs is the Technology Management and Digital Transformation program where you find our specialization in Digitalization and Automation. The structure of our specialization is as follows:

- A set of 5 basic courses where the students choose 4 out of these courses

- A set of specialization courses in digitalization and automation where the students choose 4 out of these courses, see a list of current courses below

- A master project where the student typically applies theory from the program on a relevant use case in her/his own company.

For continuing education programs it is expected that the student studies in parallel with ordinary work which means that the duration of the program is around 4 years. There is no required sequence of the courses to follow, but for some courses there is a recommended sequence.

To be admitted to the master program it is required to have a BSc degree in a technology discipline and minimum two years of relevant work experience.

Time table

The schedule for the courses in the specialization are as follows:

| Course name | Contacts | Semester |

| Remote operations | Elena Parmiggiani, Vidar Hepsø | September 16 & 17 and October 14 & 15 - 2025. Sign up ☑. |

| Maintenance optimization | Jørn Vatn | October 7, 8 & 9 and November 18, 19 & 20 - 2025. Sign up ☑. |

| Petroleum Cybernetics for Engineers and Managers | Alexey Pavlov | Autumn 2025. Sign up ☑. |

| Safety and Reliability | Jørn Vatn | Spring 2026. Sign up ☑. |

| Demonstrating Safety of Novel Solutions | Jørn Vatn | Spring 2026. Sign up ☑. |

Description of the specialization courses

PK6018 - Safety and Reliability

PK6021 - Maintenance optimizaiton

IT6207 - Remote operations

PG6210 - Petroleum Cybernetics for Engineers and Managers