Innovation

BRU21 Innovation

BRU21 Innovation

Innovation is among the top priorities for the BRU21 program. Most BRU21 research results are transferred directly to the partner companies. Research results with a broader potential impact are turned into innovation projects. These projects are supported by NTNU Technology Transfer AS, with IP protection, securing investments for further development and commercialization, and establishing startup companies and licensing agreements.

Startups

Startups

COMPUTERWELL: High-Performance Digital Twin of Drillstring Dynamics

ComputerWell delivers software for surveillanceof ongoing and historic drilling operations for the purpose of decision support. Read more about ComputerWell.

Contact person: Professor Sigve Hovda

PRODECS: Software for Project Economic Analysis under Uncertainty

ProDecs is a software for project economic analysis under uncertainty. The BRU21 research project on valuation of marginal fields has resulted in methods that can be extended and used throughout the whole industry. Read more about ProDecs.

Contact persons: Dr. Semyon Fedorov and Professor Verena Hagspiel

DIGIWELLDATA: Remote / Automated Drilling Operation

DigiWellData focuses on developing applications to optimize Drilling and Completion operations and Well integrity for the purpose of remote and automated operation. Read more about DigiWellData.

Contact person: Professor Behzad Elahifar

Innovation Projects

Innovation Projects

DrillFeel: Increasing Driller’s Situational Awareness

DrillFeel is a technology that uses haptic feedback to increase driller’s awareness of the downhole and top-side drilling process. Read more about DrillFeel.

Contact person: Professor Alexey Pavlov

OSDU Innovation Lab: Innovation Laboratory on Open Subsurface Data Universe

In collaboration Equinor and AkerBP, BRU21 is establishing an Innovation Laboratory on Open Subsurface Data Universe. Read more about OSDU.

Contact persons: Professor Eric Monteiro and Mahdis Moradi

PERMEAN: Rapid downhole testing of permeability anisotropy

BRU21 Dr. Guowen Lei developed a novel method for reducing the time needed to conduct downhole testing of permeability anisotropy, as well as increasing the testing accuracy. Read more about PERMEAN.

Contact person: Professor Milan Stanko

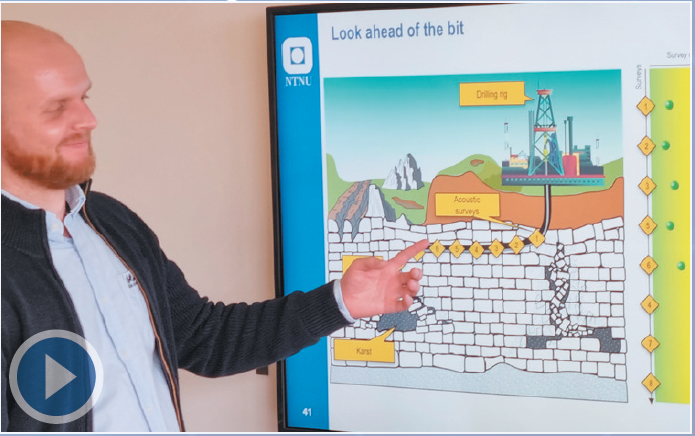

MAC: Acoustic look-ahead technology based on machine learning

The method is based on a new way of conducting acoustic surveys (Method of Acoustic Comparisons) and machine learning for processing the test data. Read more about MAC.

Contact person: Professor Alexey Pavlov

ADF: Drilling Data Analytics tool

The BRU21 team developed a method, called Adaptive Differentiating Filter, which solves this problem by automatically tuning filter parameters to the signal properties in real time. Read more about ADF.

Contact person: Professor Alexey Pavlov