Operations, maintenance, safety and security

BRU21: NTNU’s Research and Innovation Program in Digital and Automation Solutions for the Oil and Gas Industry. We mobilize multidisciplinary expertise across NTNU and, in cooperation with industrial partners, produce research results for novel technological and organizational solutions. The program consists of over 30 PhD and PostDoc projects supported by NTNU and 9 Oil and Gas and Technology companies. …read more

Video newsletters: In this series of newsletters we present BRU21 projects and selected results in the form of short videos covering each of the 6 program areas.

BRU21 program area: Operations, maintenance, safety and security

Digital and automation solutions for optimized maintenance, improved safety and reliability and higher security levels

The basis for the program area on operation, maintenance, safety and security is the opportunities and challenges we see in light of the digitalization & automation taking place these days. Within the field of operation and maintenance includes predictive maintenance/real-time monitoring of asset condition…read more

Identifying customer returns in production using the Mahalanobis distance:

Sølvsberg´s PhD project has developed a method for multivariate outlier detection that has been verified in the manufacturing sector. The remaining work entails connecting this method to digitalization/Industry 4.0 and Smart Maintenance in order to provide improved decision support for the ongoing life extension efforts on the Norwegian Continental Shelf

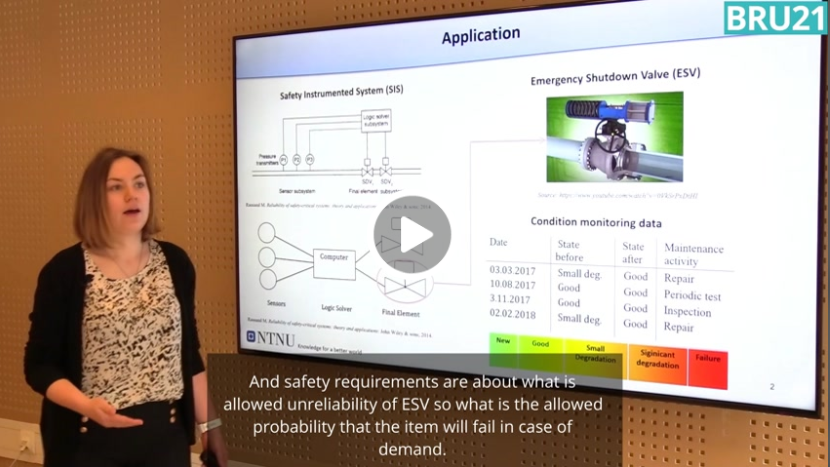

Inspection strategies for safety instrumented systems

Ewa Laskowska's PhD project has developed a model for optimizing inspection strategies where she can handle both ageing effects and the model allows the operator to use longer interval in situations where the condition is rather good and then reduce the intervals as the valve is deteriorating.

BRU21 project: Maintenance optimization in remote operations

Developing predictive maintenance models for critical assets using data and a framework for decision support systems

Project result: Maintenance decision support in remote operations

A framework using predictive maintenance and grouping optimization to find best inspection and maintenance dates

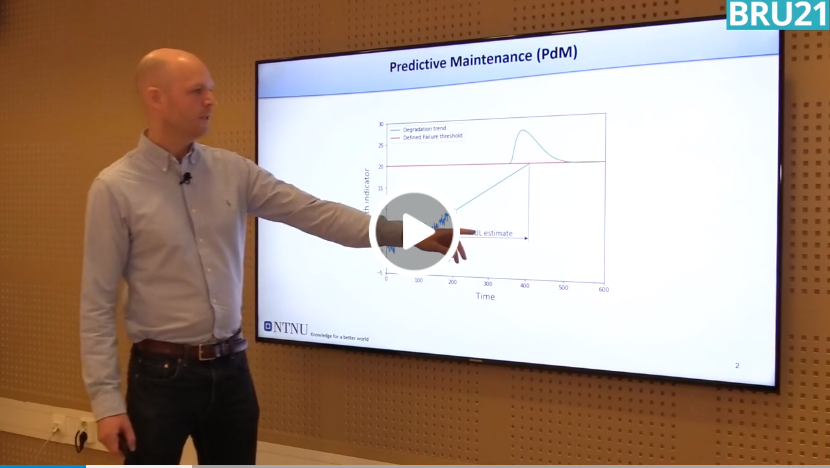

BRU21 Project: Predictive maintenance

An algorithm for maintenance optimization and prognosis of safety critical valves using stochastic modeling

Project result: Optimization of testing strategy for Emergency Shutdown Valves

A study case where condition-based testing allows to reduce the number of tests and repairs without increasing the probability of failure on demand

BRU21 Project: Industry 4.0 and smart predictive maintenance

Leveraging sensor data to better predict remaining useful life of components and enable predictive maintenance

Project result: Predictive maintenance on centrifugal pumps

A study case predicting remaining useful life using head degradation data which allows to plan timely maintenance operations considering uncertainty

BRU21 Project: Risk-based maintenance

Developing smart methods and advanced modeling to optimize and improve maintenance practices in a safe and sustainable manner.

BRU21 Project: Extending lifetime of Norwegian oil installations using predictive maintenance

Optimizing maintenance management strategies using condition monitoring and estimation of remaining useful life.

Other BRU21 video-newsletters can be found here