Operations, maintenance, safety and security

MENU

Operations, maintenance, safety and security

Operations, maintenance, safety and security

The basis for the program area on operation, maintenance, safety & security is the opportunities and challenges we see in light of the digitalization & automation taking place these days. Within the field of operation and maintenance this includes predictive maintenance/real-time monitoring of asset condition, with application of big data analytics and artificial intelligence/machine learning as well as “physical” achievements like use of drones and other autonomous tools. Another aspect covered in this program area is cyber security and safety of instrumented systems – areas that are even more important than before...read more

Program area team

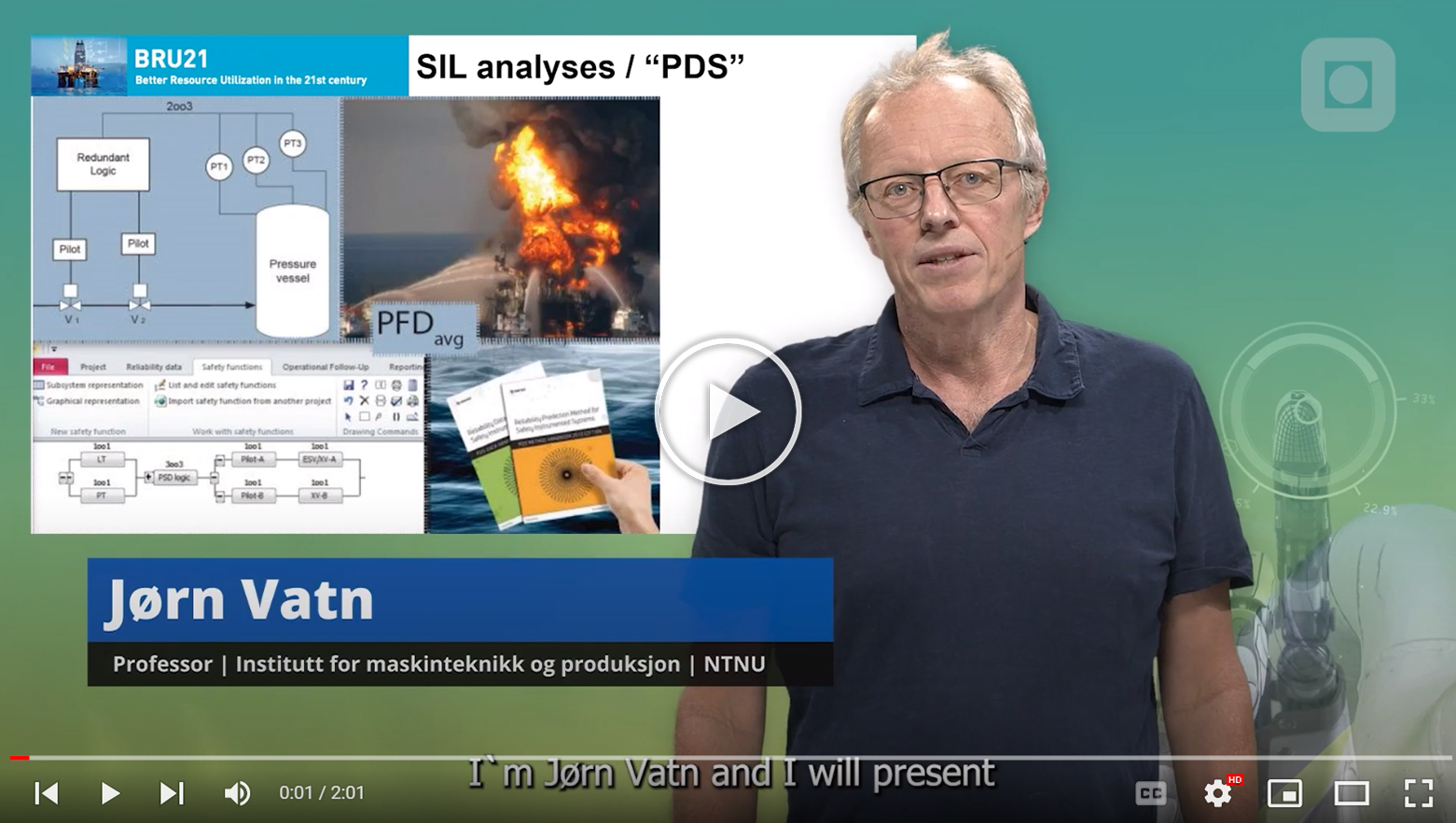

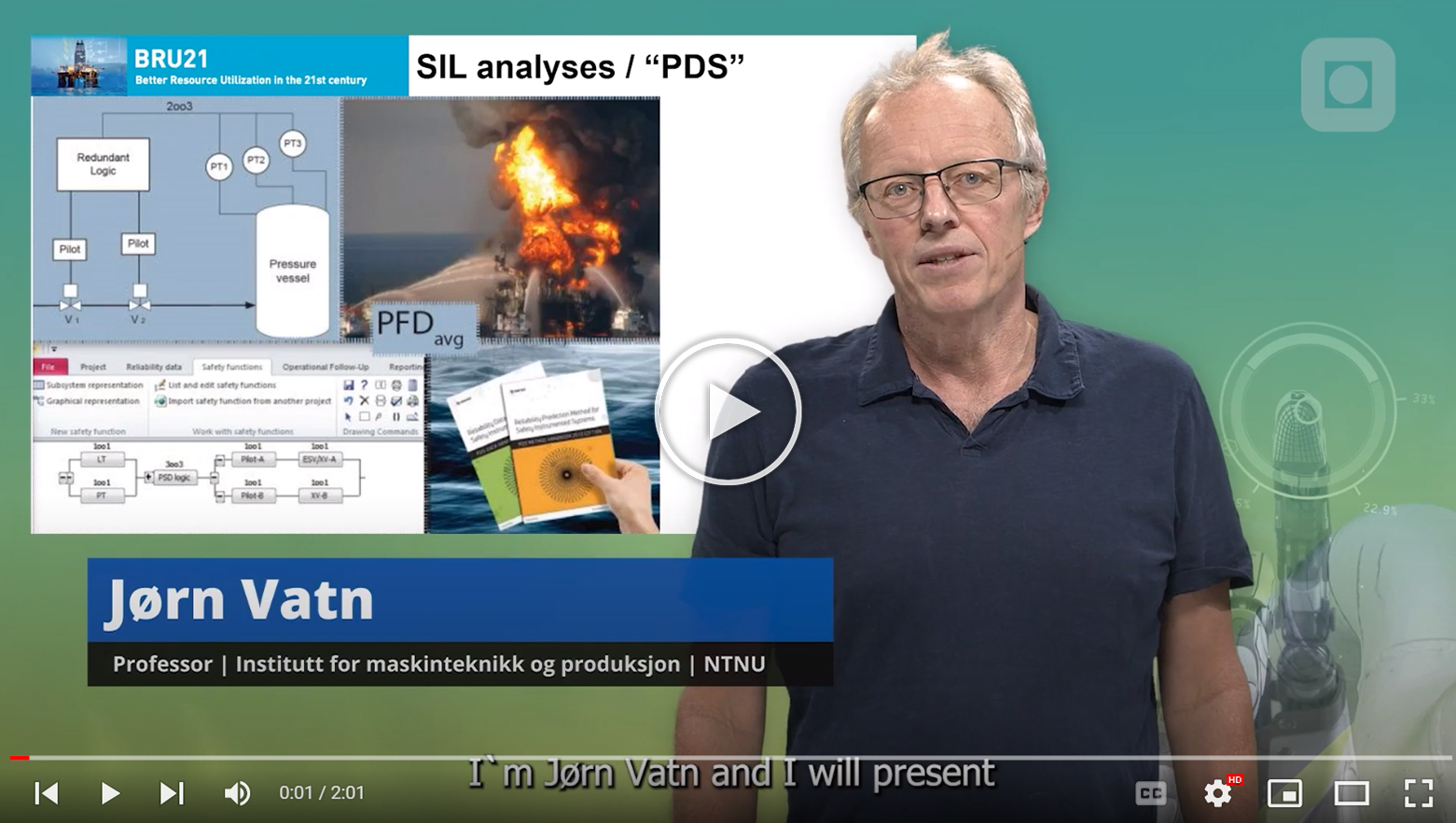

- Jørn Vatn, Prof. Maintenance, Risk & Optimization

- Mary Ann Lundteigen, Prof. Safety of Automation Systems

- Per Schjølberg, Prof. Maintenance Management and Industry 4.0

- Shen Yin, Prof. Fault diagnosis and fault-tolerance

- Pierluigi Salvi Rossi, Prof. Data fusion, sensor networks, communication and more

- Sokratis Katsikas, Prof. Cyber Security

- Bálint Zoltán Téglásy, PhD candidate

- Tom Ivar Pedersen, PhD candidate

- Abu Md Ariful Islam, PhD candidate

- Ewa Maria Laskowska, PhD candidate

- Endre Sølvsberg, PhD candidate

- Gianluca Tabella, PhD candidate

Projects

Projects

Projects

Industry 4.0 and Smart Predictive Maintenance

PhD Candidate Tom Ivar Pedersen, Main Supervisor Per Schjølberg, Sponsor: Lundin Energy Norway AS

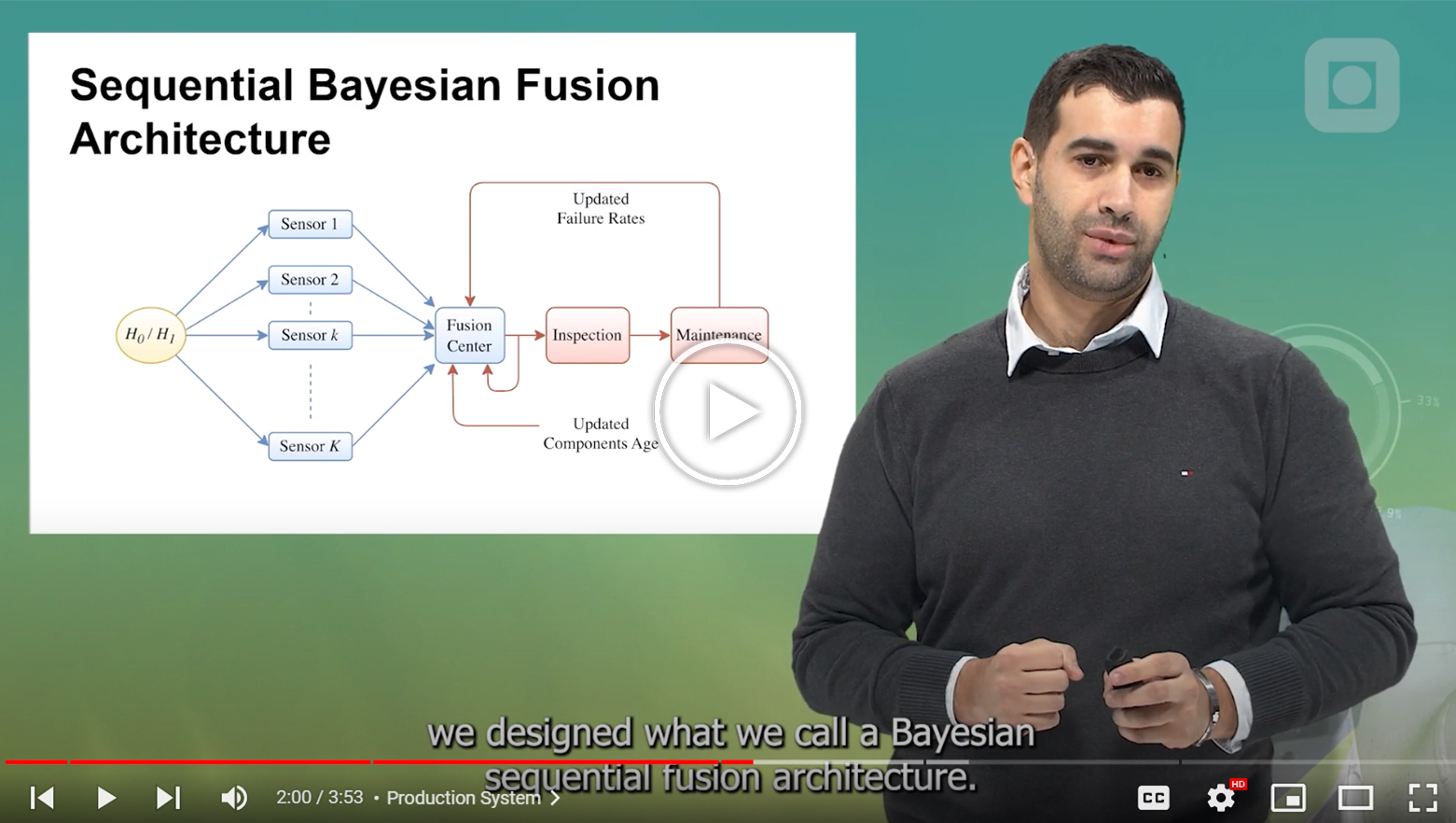

Maintenance optimization in remote operations

PhD Candidate Ariful Islam Abu, Main Supervisor Jørn Vatn, Sponsor: Aker BP

SIL analyses

Professor Jørn Vatn, PhD Candidate Ewa Laskowska

Safety and security in design and operation of ICS systems

PhD Candidate Bálint Zoltán Téglásy, Main Supervisor Mary Ann Lundteigen, Sponsor: NTNU

Extending lifetime of Norwegian oil installations using predictive maintenance through condition and remaining useful life estimation

PhD Candidate Endre Sølvsberg, Main Supervisor Per Schjølberg, Sponsor: OKEA

Predictive maintenance

PhD Candidate Ewa Laskowska, Main Supervisor Jørn Vatn, Sponsor: Lundin Energy Norway AS

Risk based maintenance

PhD Candidate Markus Bratland Kvammen, Main Supervisor Per Schjølberg, Sponsor: Equinor

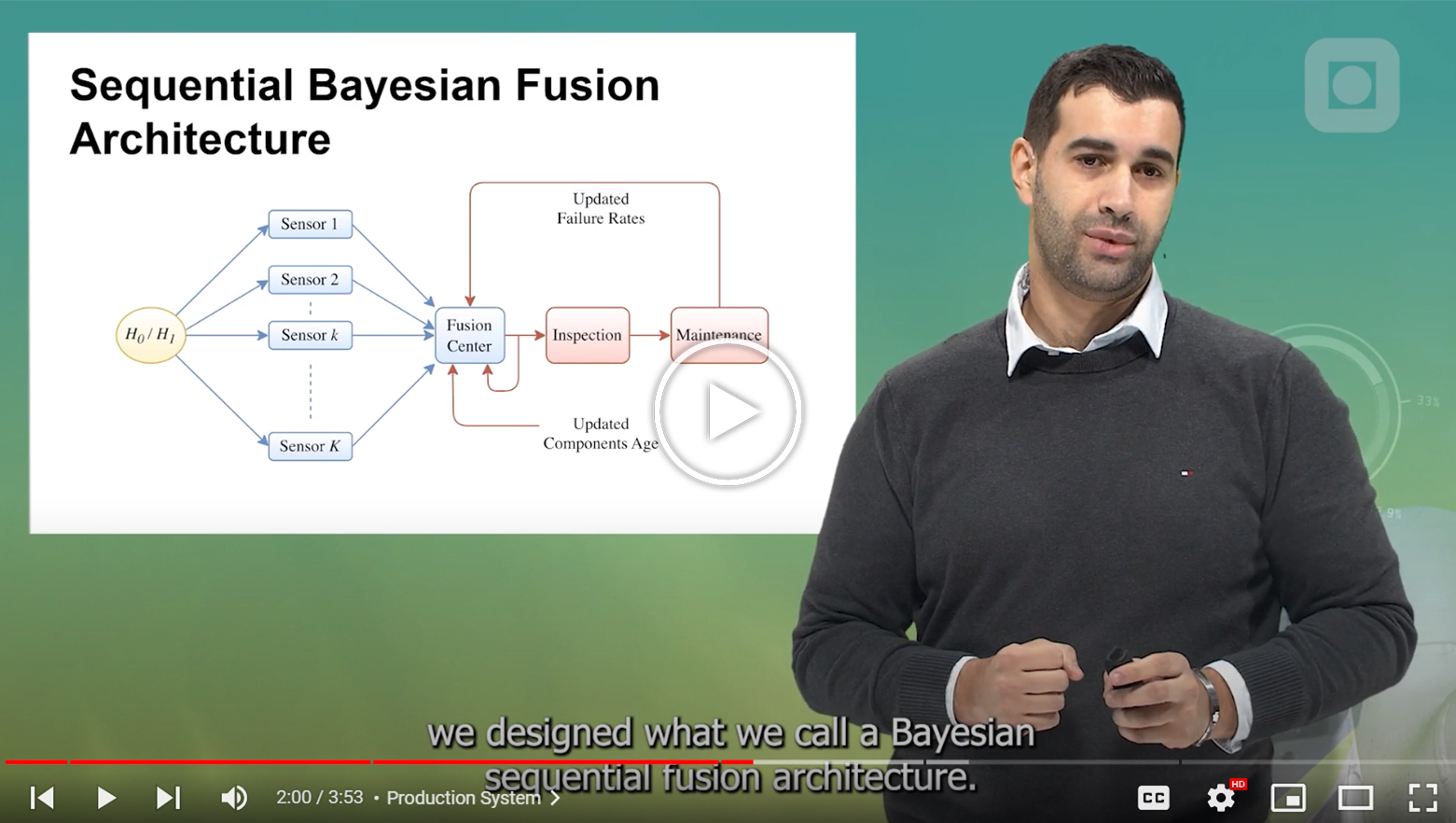

Subsea Leak Detection and Localization

PhD Candidate Gianluca Tabella, Main Supervisor Pierluigi Salvi Rossi, Sponsor: NTNU