M-HEAT

Multiscale Hydrogen Embrittlement Assessment for Subsea Conditions (M-HEAT)

Multiscale Hydrogen Embrittlement Assessment for Subsea Conditions (M-HEAT)

Objectives

The primary objective for the M-HEAT project is to establish a hydrogen informed framework for accurate and cost-effective engineering assessment of industrially relevant materials exposed to hydrogen in subsea conditions. The secondary objectives are to:

- Study the hydrogen uptake and diffusion under realistic subsea operating conditions

- Explore the hydrogen affected deformation and failure mechanisms of subsea materials by integrating multiscale experiments and simulations

- Derive a mechanism-based hydrogen failure criterion for targeted materials and conditions

- Develop and validate a multiscale hydrogen assessment framework for commercial alloys

- Educate 3 PhD candidates in materials technology, hydrogen embrittlement and material mechanics for the Norwegian industry.

How hydrogen causes transgranular to intergranular fracture transition?

How hydrogen causes transgranular to intergranular fracture transition?

August 2022 Acta Materialia 239(156-163):118279

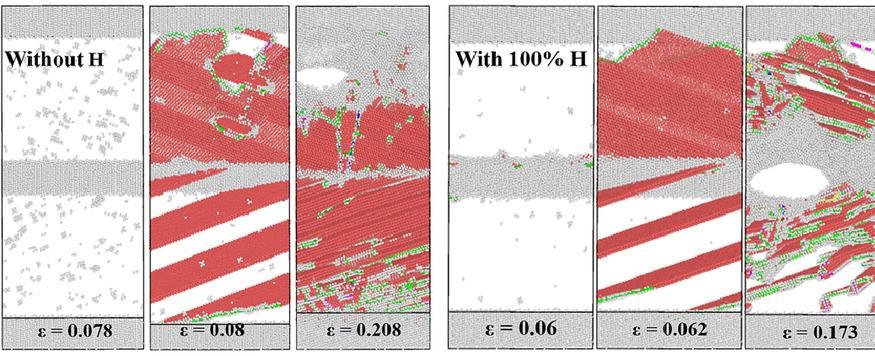

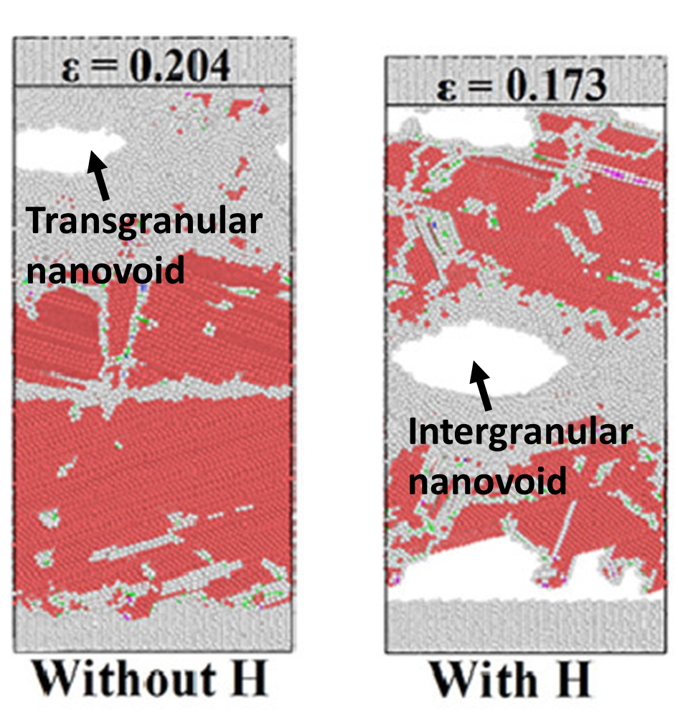

Without hydrogen, vacancy generation at grain boundary is limited and transgranular fracture mode dominates. When charged, hydrogen as a booster can enhance strain-induced vacancy generation by up to ten times. This leads to the superabundant vacancy stockpiling at the grain boundary, which agglomerates and nucleates intergranular nanovoids eventually causing intergranular fracture.

Find full article in ScienceDirect here.

A predictive model unifying hydrogen enhanced plasticity and decohesion

A predictive model unifying hydrogen enhanced plasticity and decohesion

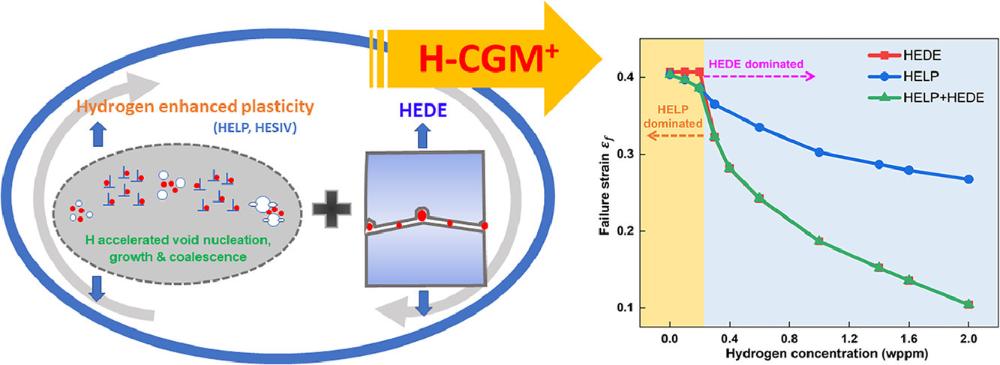

Thanks to the potential of hydrogen as a carbon-free energy carrier, hydrogen embrittlement, a 150 years old problem, has recently received an exponentially growing interest. Historically, hydrogen enhanced plasticity and hydrogen enhanced decohesion have been treated separately. In this work, we for the first time, presented a model which can unify these two failre modes together in a computational framework, capturing the full transition of hydrogen induced ductile to brittle fracture transition.

A hydrogen embrittlement predictive model unifying plasticity and decohesion.

Hydrogen-induced transgranular to intergranular fracture transition

Hydrogen-induced transgranular to intergranular fracture transition

A new paper published in Scripta Materialia

The manuscript demonstrates the direct transgranular to intergranular fracture transition process controlled by hydrogen-influenced plasticity, by scrutinizing the tensile responses of Ni Σ5(210)[001] GB with varied hydrogen concentration using atomistic modeling. Compared with the Σ3 coherent twin GB which traps nearly no H atoms, H will form an atmosphere at the Σ5 GB due to the high trapping energy and excess volume and induce a higher initial local stress. In the case without H, less stress is built up at the Σ5 GB region during deformation, which leads to transgranular fracture. In contrast, H suppresses the stress-releasing ability of the Σ5 GB, which causes a local stress concentration and promotes local plasticity on the GB. This further leads to early dislocation emission, severe twinning evolution, increased number of vacancies and thus enhanced nanovoiding on the GB. The growth of nanovoids with H finally completes the transgranular to intergranular-fracture transition. These findings enrich our knowledge of hydrogen-induced intergranular fracture at the microscale.

Popular science presentation of the M-HEAT project in English

Popular science presentation of the M-HEAT project in English

While Norwegian continental shelf calls for development of new material solutions to handle harsher conditions, or development of subsea gas processing systems, the material integrity in the intended conditions must be secured - including the effects of hydrogen exposure. Hydrogen embrittlement is a long-standing challenge for the subsea industry and a critical failure mode that must be considered in life extension strategy. The current framework for assessing hydrogen embrittlement of subsea components is limited to duplex stainless steels. A practical framework to quantitatively address hydrogen embrittlement of other subsea material groups is missing. Although significant efforts have been made to understand hydrogen embrittlement, today’s theories still offer a qualitative and binary treatment of hydrogen embrittlement. For industrial applications, a quantitative prediction is needed. Hence a gap exists which restricts direct application of scientific understandings in practical engineering.

This project aims to enable prediction of hydrogen embrittlement when designing subsea components and to evaluate hydrogen embrittlement sensitivity of materials. This will be accomplished by developing and implementing a new multiscale assessment framework for hydrogen embrittlement. The proposed solution represents an efficient and accurate methodology to address hydrogen embrittlement. It provides quantitative methods to reduce and manage uncertainty and thereby risk. With reduced risk, the safety factors can be optimized to allow more cost-effective solutions through savings in material use, project execution and product development. The proposed solution can be extended beyond the oil and gas industry to the renewable energy sector, e.g. offshore windmills, to the fuel cell industry and others

Popular science presentation of the M-HEAT project in Norwegian

Popular science presentation of the M-HEAT project in Norwegian

Mens norsk kontinentalsokkel krever utvikling av nye materialløsninger for å håndtere tøffere forhold, og for utvikling av undervanns olje- og gassprosessingssystemer, må materialers integritet i de faktisk forholdene sikres. Dette inkludert også virkningen av eksponering mot hydrogen. Hydrogensprøhet har vært en utfordring for undervannsindustrien i mange år, som også må vurderes i forbindelse med levetidsforlengelse av strukturer og utstyr. Det eksisterende rammeverket for å vurdere hydrogensprøhet av utstyr og komponenter under vann er begrenset til dupleks rustfrie stål (DNVGL RP F112). Et praktisk rammeverk for kvantitative analyser av hydrogensprøhet for andre materialgrupper som brukes under vann, mangler. Selv om det er gjort store anstrengelser for å etablere en bedre forståelse for fenomenet hydrogensprøhet, gir eksisterende teorier fortsatt kun en kvalitativ og binær behandling av hydrogensprøhet. For industrielle anvendelser er det nødvendig med kvantitativ prediksjon. Derfor eksisterer det i dag et gap som begrenser direkte anvendelse av vitenskapelige resultater i praksis.

Dette prosjektet tar sikte på å utvikle et multiskala-rammeverk som gjør det mulig å forutse hydrogensprøhet, når undervannsutstyr- og komponenter designes for bruk under vann, og å evaluere ulike materialers følsomhet for hydrogensprøhet. Den foreslåtte løsningen representerer en effektiv og nøyaktig metode for å behandle hydrogensprøhet. Løsningen gir kvantitative metoder for å redusere og håndtere usikkerhet og dermed risiko. Med redusert risiko kan sikkerhetsfaktorene optimaliseres for å gi mer kostnadseffektive løsninger gjennom besparelser i materialbruk, prosjektutførelse og produktutvikling. Andre sektorer innenfor fornybar energi som f.eks. offshore vindmøller og design/bruk av brenselceller vil også ha nytte av resultatet fra prosjektet.

M-HEAT info

M-HEAT info

Duration: 2019-2022

Funding: 9.8 mKr from the Research Council of Norway via the PETROMAKS 2 Program and about 2.5 mKr from the industrial partners.

M-HEAT members

M-HEAT members

Professor Zhiliang Zhang, NTNU

Project leader

PhD supervisor

Professor Alexey Vinogradov, NTNU

PhD supervisor

Professor Roy Johnsen, NTNU

PhD supervisor

M-HEAT Industrial partners

M-HEAT Industrial partners

Jim Stian Olsen

Aker solutions

jim.stian.olsen@akersolutions.com

Tore R Andersen

Equinor Energy AS

Ragnar Vaksdal

Voestalpine High Performance Metals Norway AS

M-HEAT International Partners

M-HEAT International Partners

Ghent University, Belgium

Professor Alan Cocks

University of Oxford, UK

Professor Michael Ortiz

Caltech, USA

Professor Mariano Iannuzzi

Curtin University