Powder Diffraction Lab - Department of Materials Science and Engineering

X-ray powder diffraction laboratory (XRD-Lab)

X-ray powder diffraction laboratory (XRD-Lab)

X-ray diffraction is a central technique in the investigation of condensed matter, providing direct insight into the crystal structures of materials.

It is a very flexible method also, with applications ranging from quantitative assessment of industrial feed and product materials to complex crystal structure determination. Modern laboratory scale instrumentation is both fast and easy to use, and is consequently ubiquitous in both research and industrial analysis laboratories.

The powder diffraction facility at the Institute for Materials Technology was established in its modern form in 1997, and has grown since then to service the needs of both IMA and the wider NV Faculty. The lab is part of the Norwegian Centre for X-ray Diffraction, Scattering and Imaging REsource Centre X-rays (RECX), a virtual centre spanning the Departments of Materials and Physics at NTNU and the Department of Chemistry at the University of Oslo.

Currently we boast state-of-the-art diffraction facilities for the analysis of powders and solid compacts and we are open to users from all NTNU and SINTEF departments and also to external users via agreement with the laboratory engineer. The X-ray diffraction lab is primarily "user-operated", with routine data collection and analysis being performed by researchers themselves. In this way we complement the educational role of the University, with on average ~60+ new users being trained every year.

Instruments

We currently have five instruments with sample holders and ancillary equipment enabling the collection of data on a broad variety of specimens and under non-ambient environmental conditions.

Bruker D8 Focus

Bruker D8 Focus, with CuKα radiation (i.e. wavelength of 1.54 Å, 9 position sample changer and LynxEye™ SuperSpeed Detector. This instrument is suited for routine X-ray powder diffraction.

More information about the Bruker D8 Focus

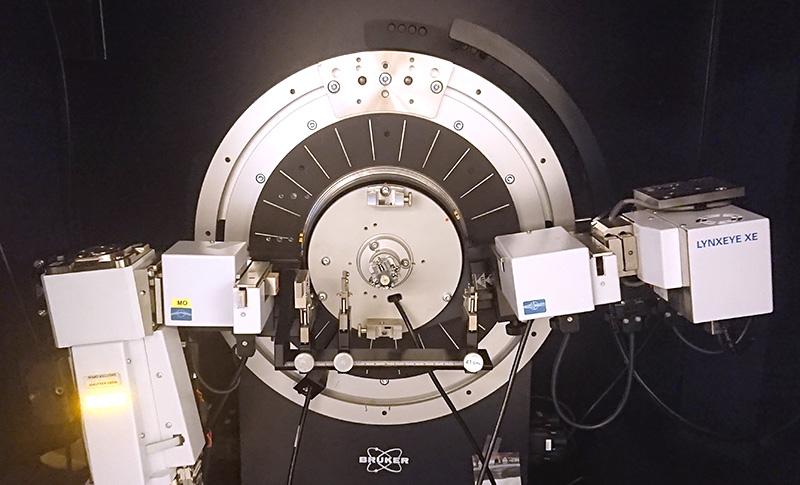

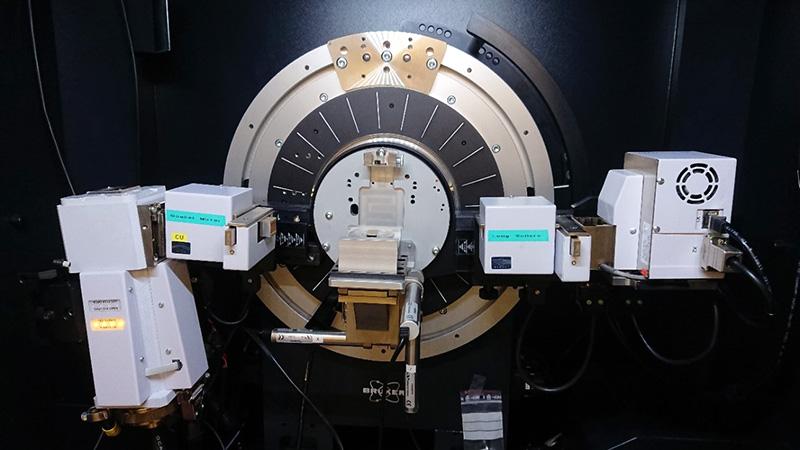

Bruker D8 A25 DaVinci (DaVinci 1)

Bruker D8 A25 DaVinci (DaVinci 1) with CuKα radiation, 60 position sample changer and LynxEye™ SuperSpeed Detector. The instrument can be changed between Bragg Brentano and parallel beam geometry. This instrument is suited for routine X-ray powder diffraction and GIXRD. Energy-discriminating detector makes it useful for sample that contain Fe, Co, Mn.

More information about the Bruker D8 A25 DaVinci (DaVinci 1)

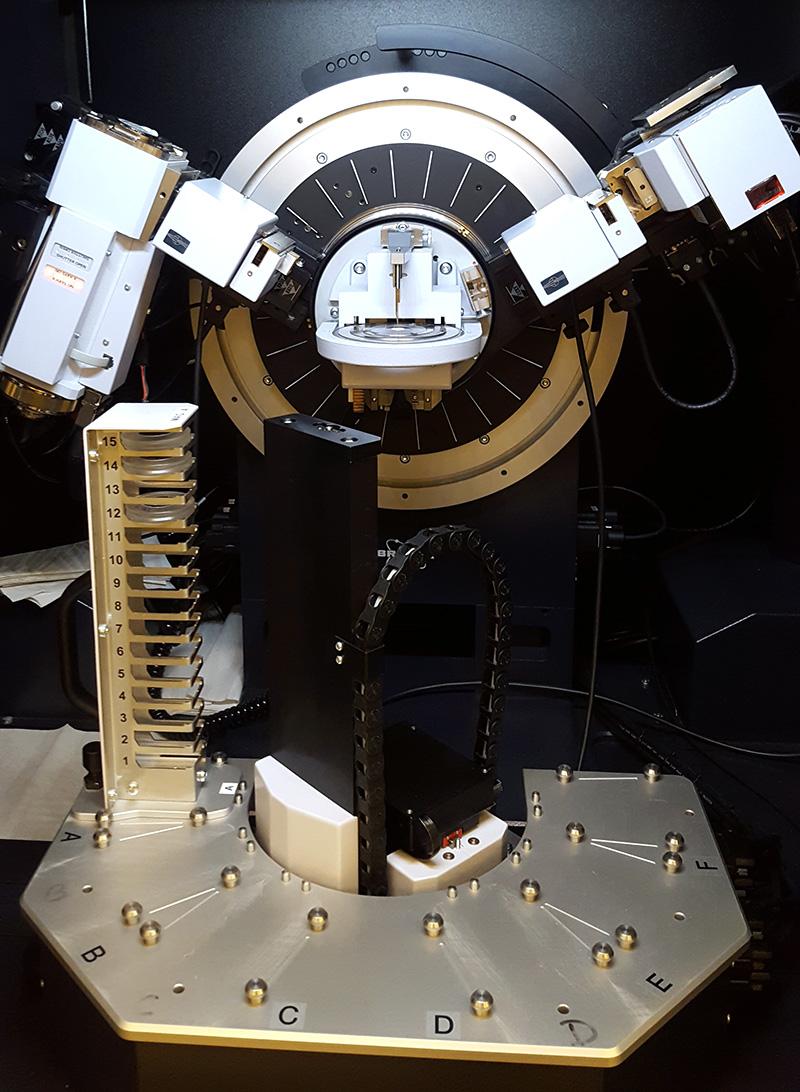

Bruker D8 A25 DaVinci (DaVinci 2)

Bruker D8 A25 DaVinci (DaVinci 2) used for non standard set-ups. It has two sources Cu and Mo. Application with Cu radiation: GIXRD, XRR, XRD. Application with Mo radiation: Advance analysis for powder XRD (using capillary stage), suppression of fluorescence Co, Mn, Fe samples, in-situ studies on batteries or other reactions.

More information about Bruker D8 A25 DaVinci (DaVinci 2)

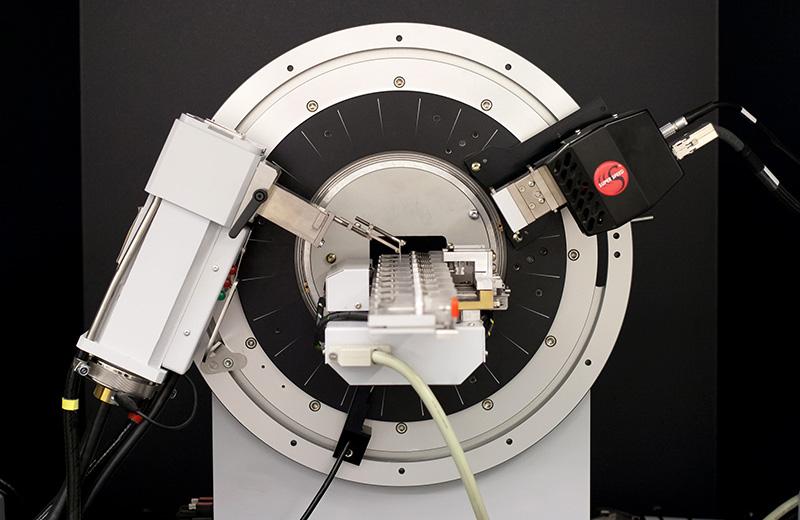

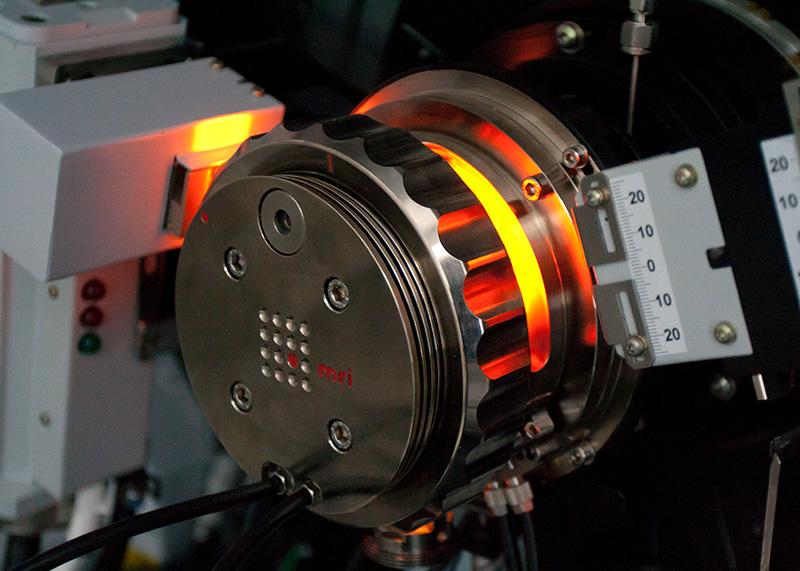

Bruker D8 Advance with Våntec-1 super-speed detector

This instrument is used for non-ambient data collection using a selection of low temperature, high temperature and high pressure sample stages covering a temperature range of -190°C to 1400°C, under inert and reactive atmospheres up to 10 bar pressure.

More information about the Bruker D8 Advance with Våntec-1 super-speed detector.

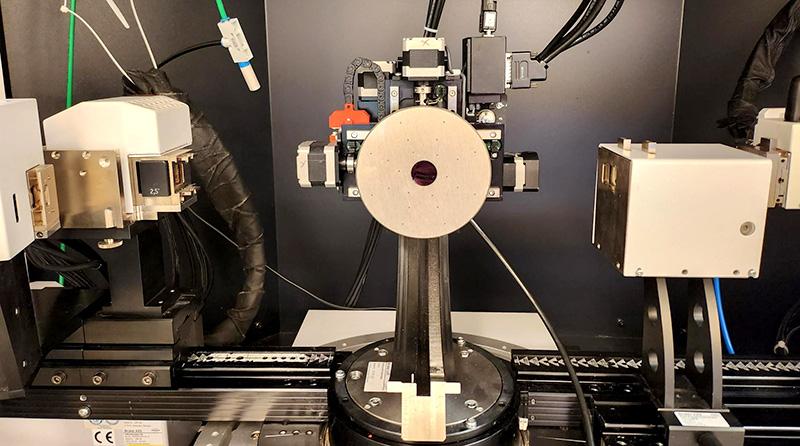

Bruker D8 Discover

Bruker D8 Discover with Ge-002 monochromator with CuKα1 radiation for thin film studies. This is instrument is suitable for XRR, GIXRD, HR-XRD studies.

More information about the Bruker D8 Discover

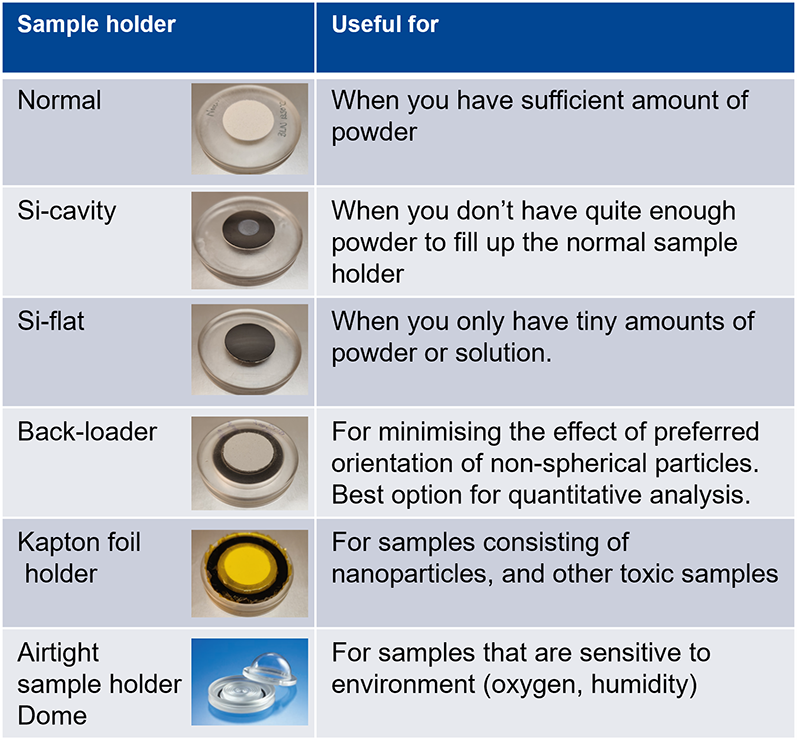

We have also various sample holder that allows performing measurement from solution, nanoparticules, toxic samples, solid samples and air-sensitive samples.

To aid data analysis and interpretation the laboratory offers a wide range of software analysis tools including the latest ICCD PDF4+ structural databases and the Bruker Topas Rietveld analysis software. Users also have free access to support and training with respect to their data analysis.

More information

For more detailed information of our capabilities please read the relevant sections linked to the left.

Scientific responsible: Ingrid Hallsteinsen

Enquiries regarding the laboratory: Elvia Chavez (elvia.a.c.panduro@ntnu.no)

Where to find us

The XRD lab is located in the K2-building (K2-113) on campus Gløshaugen.

Address

Sem Sælands vei 12

7034 Trondheim

Norway

Contact

Contact

Elvia Chavez Panduro

XRD lab responsible

Email: elvia.a.c.panduro@ntnu.no

Location

Sem Sælands vei 12

Kjemiblokk II K2-113

Logo - Powder Diffraction Lab